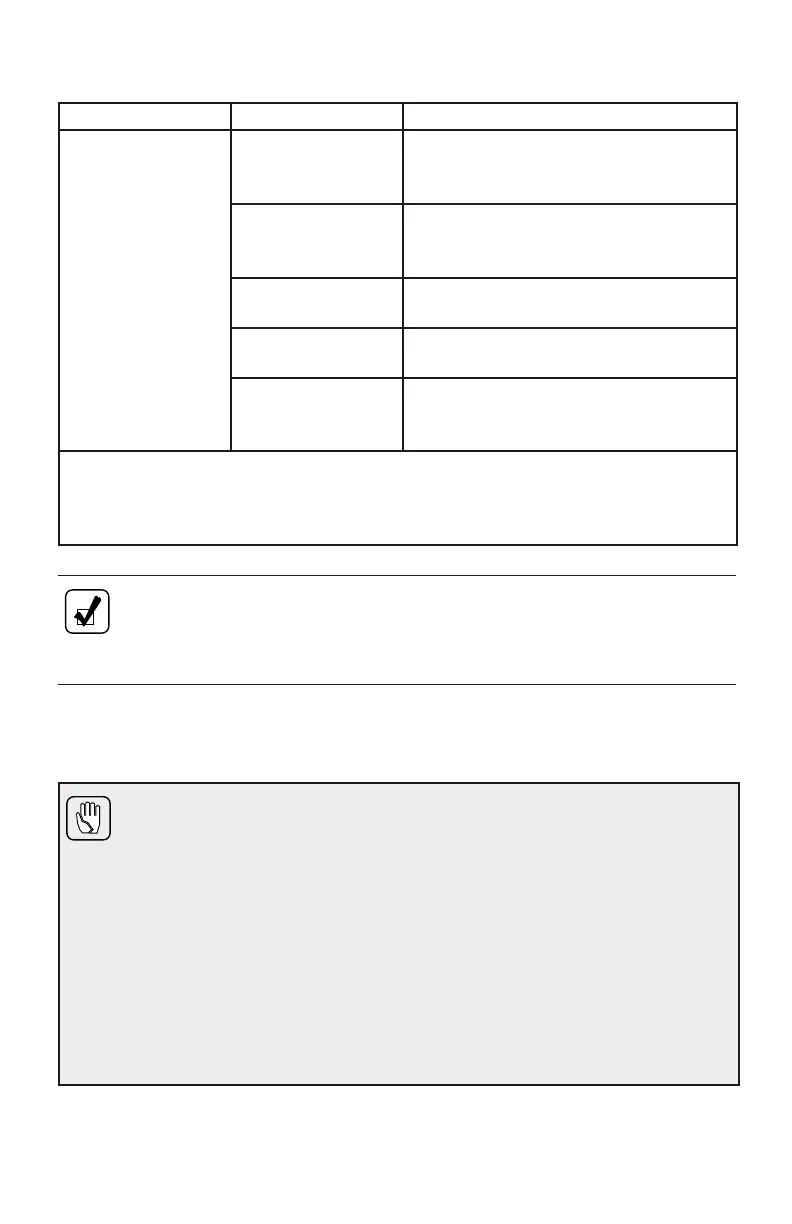

Types of Retarder Control

(cont’d)

Type Description Amount of Application

Combinations of

the above

systems **

Auto “half-on”

plus pressure

switch *

Half capacity at closed throttle or

“Full On” with brake pressure

Auto “

1

/

3

on” plus

two pressure

switches *

1

/

3

, capacity at closed throttle or

2

/

3

and “Full On” with brake pressure

Hand lever plus

pressure switch *

6 levels of modulation with lever, or

“Full On” with brake pressure

Foot pedal plus

pressure switch

Full modulation with separate pedal,

or “Full On” with brake pressure

Hand lever plus

interface for

special pedal *

6 levels of modulation with lever, or 3

levels of modulation based on pedal

position

* These control systems may apply the retarder at high speed on grades when the vehicle has road

speed limiting and the retarder is enabled.

** For retarder apply systems integrated with the service brake system, the retarder is most effective

when applied with light brake pedal pressure for 1–2 seconds to allow the retarder to fully

charge. Added pedal pressure can be applied when more aggressive braking is desired.

NOTE: When the transmission fluid or engine water temperature

(engine water is an OEM option) exceeds programmed limits, retarder

capacity is automatically gradually reduced to minimize or avoid

possible system overheating.

Contact your vehicle manufacturer to understand how the retarder controls have

been integrated into your vehicle.

CAUTION: Observe the following cautions when driving a vehicle

equipped with a retarder:

• THE RETARDER WORKS ONLY WHEN THE ENGINE IS AT

CLOSED THROTTLE.

• OBSERVE TRANSMISSION AND ENGINE TEMPERATURE

LIMITS AT ALL TIMES. Select the lowest possible transmission

range to increase the cooling system capacity and total retardation

available.

• In the event of OVERHEATING, DECREASE THE USE OF THE

RETARDER; USE THE SERVICE BRAKES TO SLOW THE

VEHICLE.

• OBSERVE THE RETARDER/SUMP “OVERTEMP” LIGHT to be

sure it responds properly to retarder temperature.

40

Loading...

Loading...