18 ALLMAND.COM

Engine Fails to Start

1. If the engine fails to start after performing starting

procedure, steps 1 - 4, do not keep the starter

running.

2. Set the starter switch to STOP, wait

approximately 2 minutes, then repeat the startup

procedure.

3. If the repeated startup procedure does not allow

the engine to run, check for the following causes:

• No fuel

• Clogged fuel filter

• Discharge of battery or low cranking speed

• Ambient temperature is too low

Starting the Compressor at Low Temperature

NOTICE When operating compressor under cold

weather conditions below

23°F (-5°C):

• Use SAE10W-30 (CJ-4) for the engine oil.

• When the unit is used in a cold region and

possible freezing is expected, it is recommended

to use LLC (Antifreeze) for the coolant.

• Adjust mixing ratio of LLC (Antifreeze) with water

according to the temperature.

• Use LLC (Antifreeze) within the range of its

mixing ratio between 35 and 60%.

• If LLC (Antifreeze) in the water exceeds more

than 60%, it may decrease its antifreezing effect.

(Upon delivery from the works, LLC density is

55%).

• Use LLC (anti-freeze) which conforms to one

of such standards: SAE JB13, SAE J1034 and

ASTEM D3306.

• Battery should always be fully charged.

• Follow the designated regulations to dispose of

LLC (Antifreeze).

When it is difficult to start engine in cold weather,

complete the following steps:

1. Fully close the service valves.

2. Start engine by following steps 1 - 6 in Starting

the Compressor.

CAUTION When operating the unit in

a low temperature, change engine oil, compressor

oil, LLC , and diesel fuel according to the ambient

temperature.

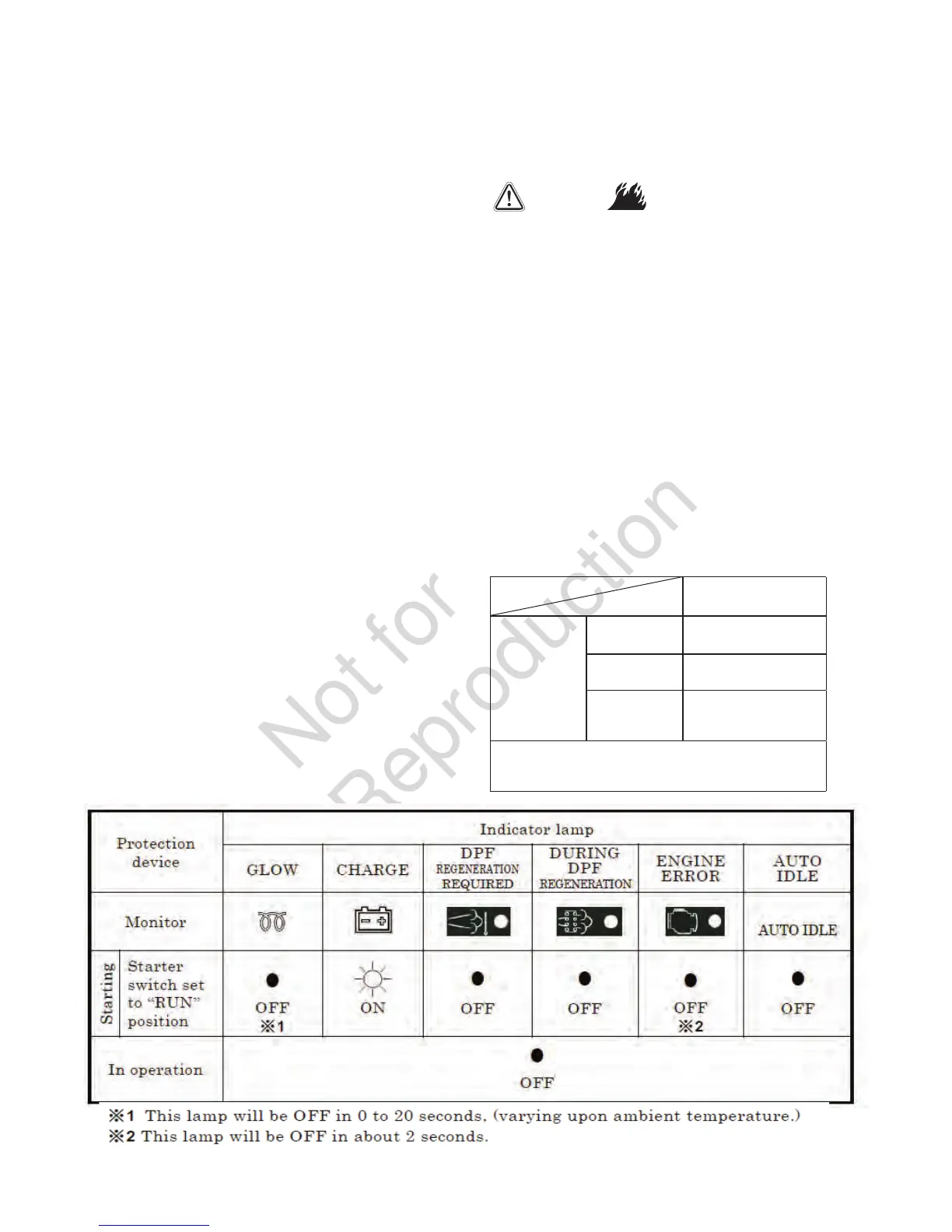

Gauge Indication While Operating Compressor

NOTICE Minimum discharge air pressure is 58 psi (4

bar) during operation. Continuing equipment operation

at a lower pressure than the above pressure may

cause overheating, since it affects the separation of

lubricating oil inside the oil separator and reduces

the oil flow to the compressor air-end, resulting in

temperature rise.

• Make sure to check that gauges or each

component of the compressor are properly

working, or if there is any air-leak, oil-leak, water-

leak or fuel-leak etc.

• During normal operation, each indication of

instruments is shown in the table below. Refer to

the table for daily checks.

Discharge

Pressure Gauge

In Operation

Full Load

* 58 to 100 psi

(4 to 6.9 bar)

No Load

(Unload)

* 116 to 131 psi

( 8 to 9 bar)

At purge

control

(AUTO IDLE)

* 36 to 58 psi

( 2.5 to 4bar)

* Values may vary slightly depending on the operating conditions and

other factors.

Loading...

Loading...