26 ALLMAND.COM

• Do not operate machine or charge battery with low

electrolyte level. Doing so may damage battery, or

may cause explosion.

• Add distilled water so that electrolyte level reads

between “UPPER” and “LOWER” level.

• Do not charge frozen battery. Otherwise it may

explode. If battery is frozen, warm it up until the

battery temperature becomes 16°C to 30°C.

• Battery electrolyte is dilute sulfuric acid.

• Mishandling battery could cause severe burns.

• Wear protective gloves and safety glasses when

handling battery.

• If battery electrolyte contacts clothes or skin, wash

immediately with large amount of water.

• If battery electrolyte gets into eyes, flush with plenty

of water and seek immediate medical attention.

• Dispose of battery according to local, state and/or

federal regulations.

Check Battery Electrolyte

Standard battery:

1. Check battery electrolyte level. If low, add distilled

water.

2. Measure specific gravity of battery electrolyte. If

below 1.24, recharge battery. See Charge Battery.

Maintenance-free battery:

1. Check indicator on top surface of battery.

2. If indicator shows that charge is needed, recharge

battery.

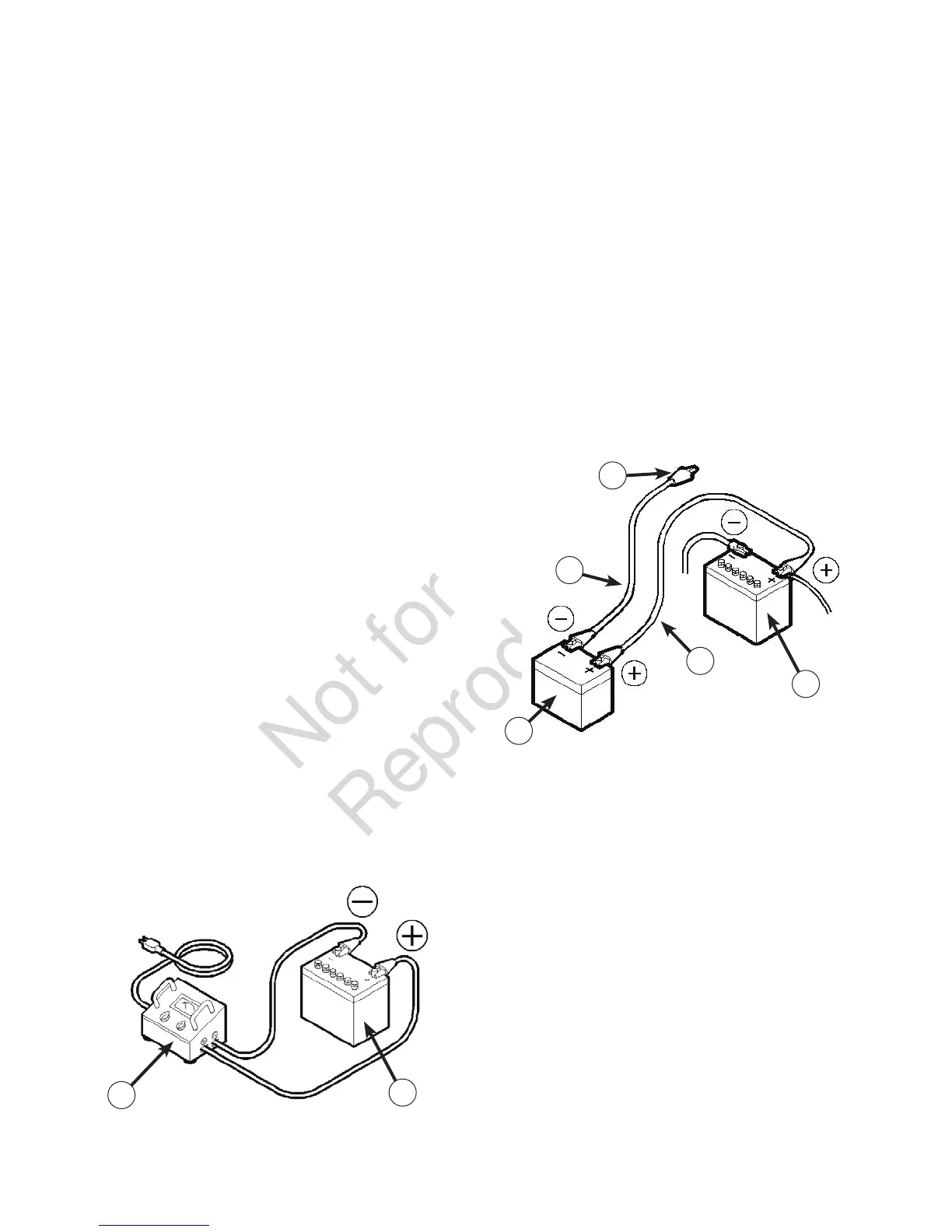

Charge Battery

1. Disconnect cables between battery and unit, black

negative (-) cable first, and charge battery (A) with

a 12-volt battery charger (B). Do not charge two

batteries at the same time.

2. Be sure not to connect (+) and (–) terminals

backwards.

3. Read operation manual of battery charger before

use.

B

A

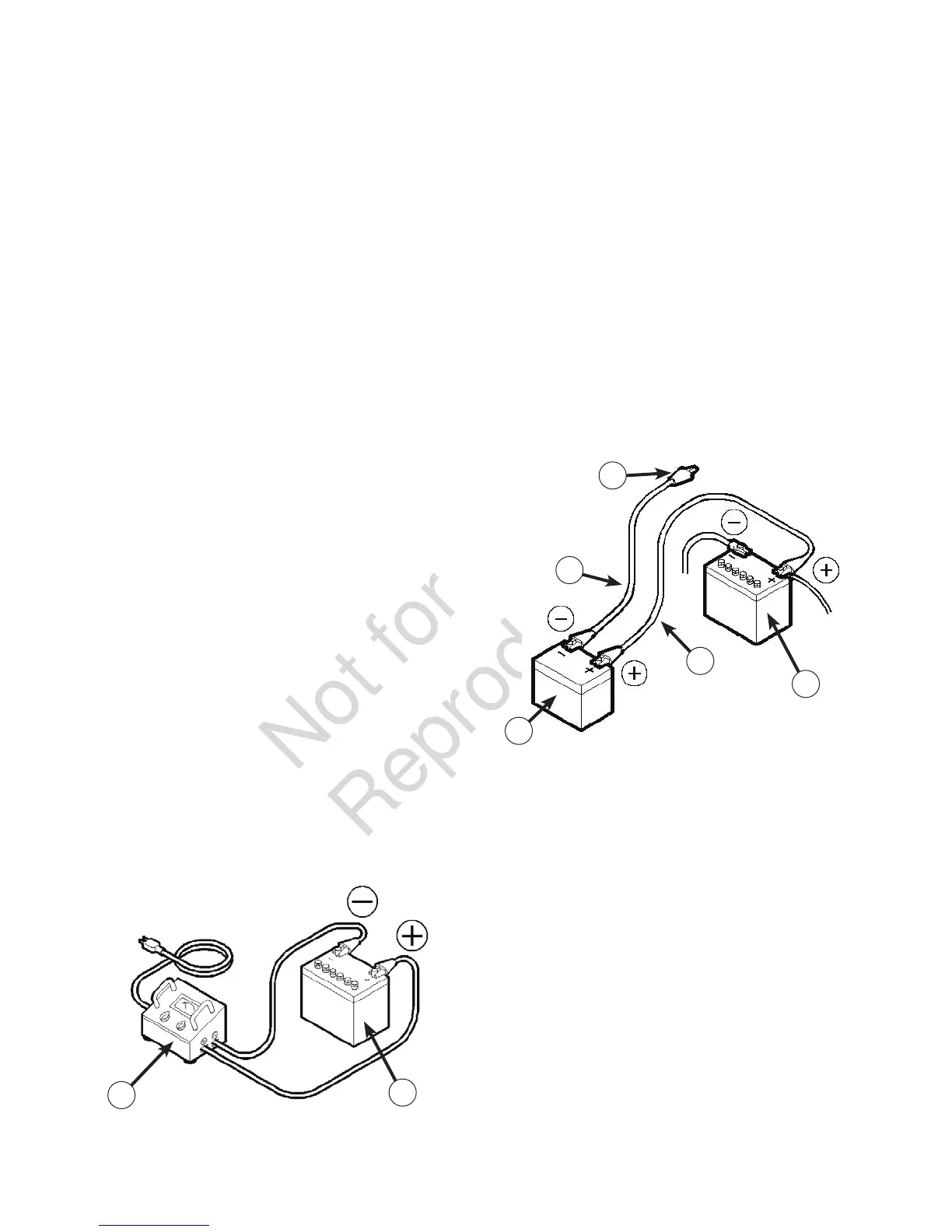

Booster Cables

To use booster cables:

1. Connect one end of red positive (+) cable (C) to

positive (+) terminal of machine battery (D).

2. Connect other end of red positive (+) cable to

positive (+) terminal of external battery (E).

3. Connect one end of black negative (–) cable (F) to

negative (–) terminal of external battery.

4. Connect other end of black negative (–) cable to

engine block of machine (G, not shown).

NOTICE

Be careful not to connect positive (+) and negative

(–) terminals backwards.

5. Start engine.

6. Disconnect booster cables by following above

procedure in reverse order.

E

F

G

D

C

Clean Air Filter Element

1. Loosen latch (B), and remove cap (A). Clean

interior of cap. Be sure O-ring (D) is properly seated

in cap.

2. Remove and clean filter element (C). If damaged

or heavily soiled, replace. (For part numbers, see

Replacement Parts.)

3. Clean interior of case (E).

4. Install filter element into case, then install cap,

securing with latch.

Loading...

Loading...