CHAPTER 3: USING PROGRAMMING FUNCTIONS

IS-300CA INVERTER POWER SUPPLY

3-14 990-418

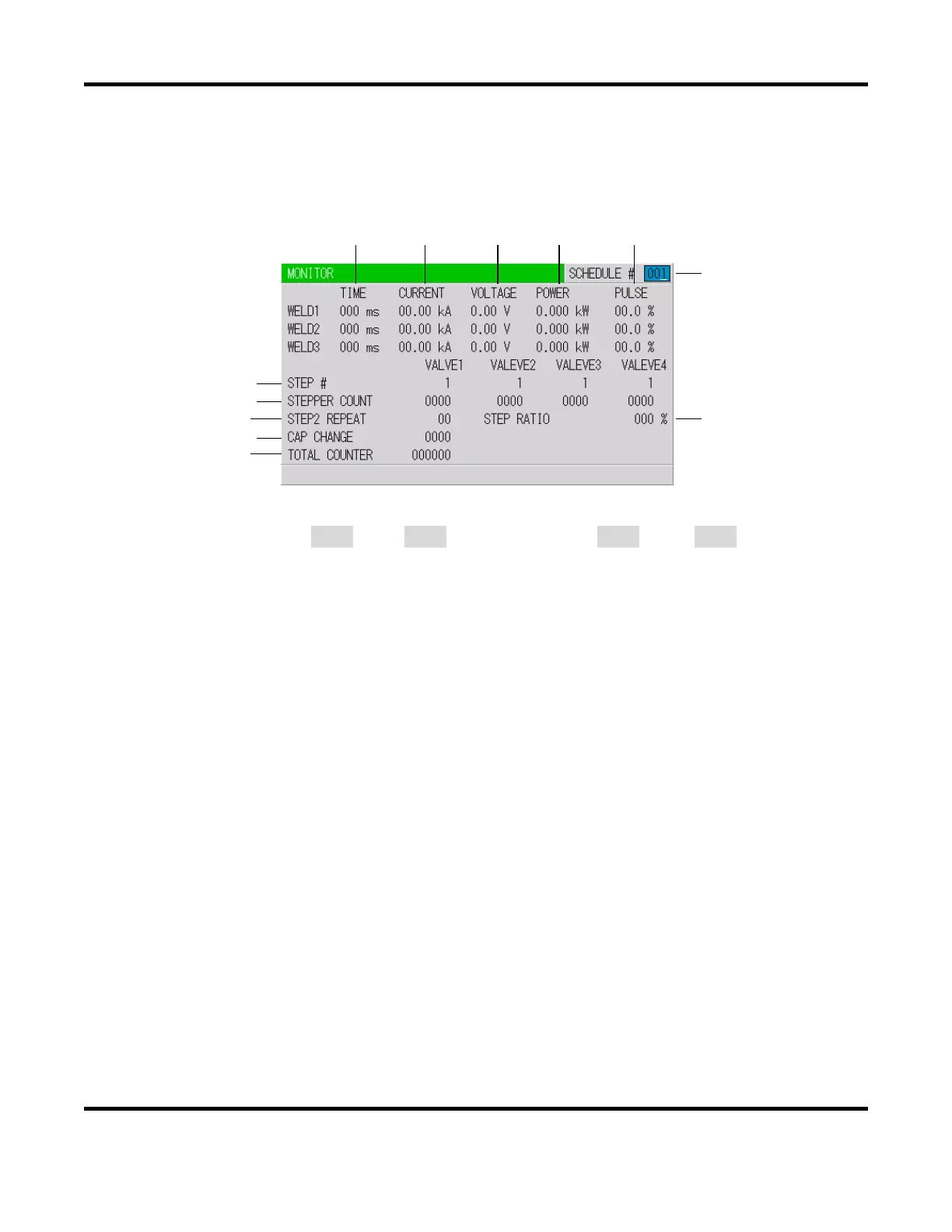

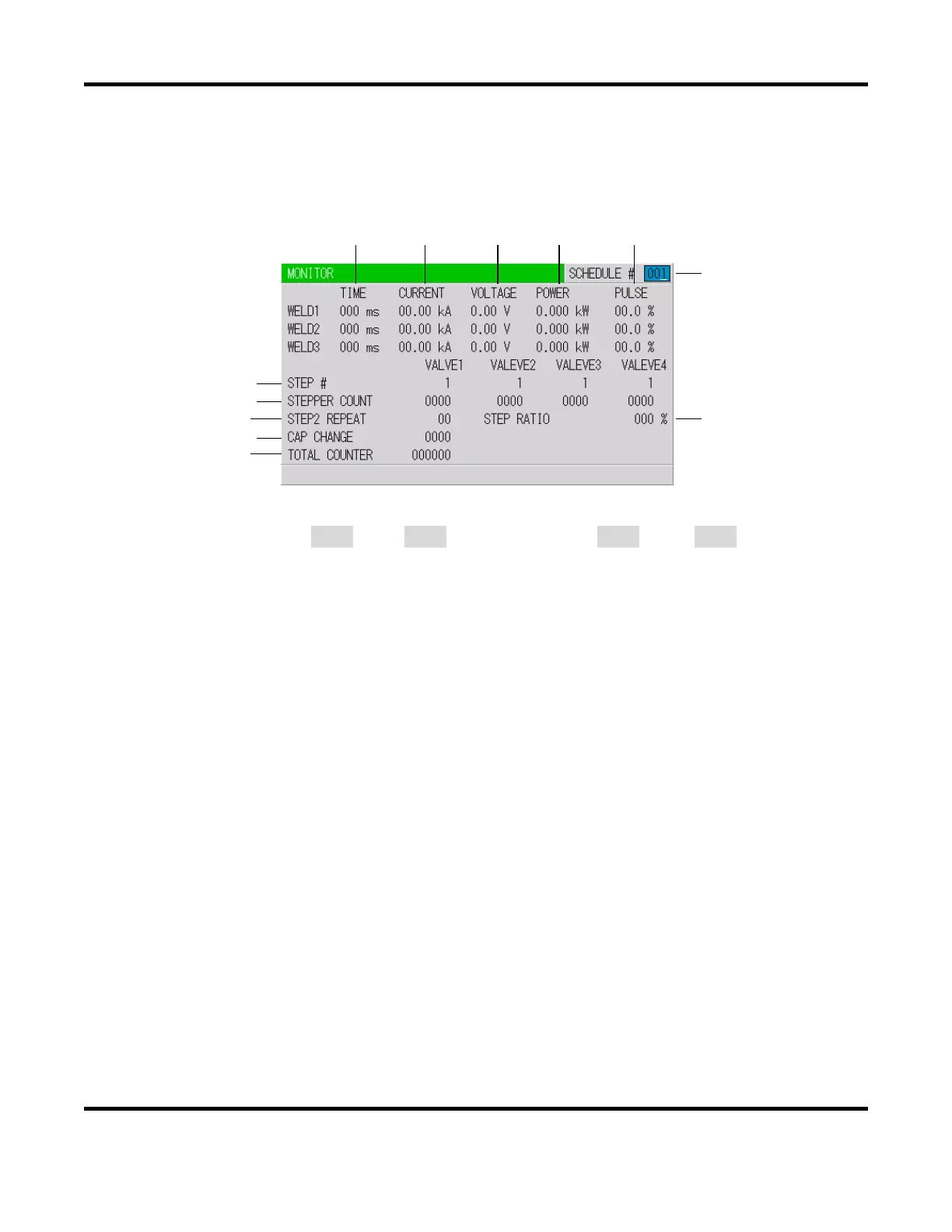

4. MONITOR Screen

In this screen, you can confirm the operational conditions during welding. Monitored data is

displayed for each SCHEDULE.

(b) (c) (d) (e) (f)

NOTE: The screen shows the settings for 10 kA or 05 kA range. In 20 kA, 40 kA, or 80 kA

range, CURRENT is 000.0 kA to 999.9 kA and POWER is 000.0 kW to 999.9 kW.

a. SCHEDULE #

Set the No. of the SCHEDULE to monitor. The measured values (welding current, voltage, etc.)

for welding within that SCHEDULE are displayed. The Power Supply stores the latest measured

values of each SCHEDULE number. The stored measurement values are not erased even when

the power is turned off, and thus can be checked for the next job.

b. TIME

The lengths of periods during which current was supplied in the course of WELD1, WELD2 and

WELD3 operations are displayed. The latest measured value welded with the displayed

SCHEDULE No. is displayed. As units of time, ms and CYC may be selected. Either unit can

be selected via the

MODE SELECT screen.

c. CURRENT

The current during which current was supplied in the course of WELD1, WELD2 and WELD3

operations are displayed. The latest measured value welded with the displayed SCHEDULE

No. is displayed.

d. VOLTAGE

The voltage during which current was supplied in the course of WELD1, WELD2 and WELD3

operations are displayed. To display the voltage, you need to measure the secondary voltage by

connecting the voltage detecting cable. The latest measured value welded with the displayed

SCHEDULE No. is displayed.

(g)

(h)

(i)

(k)

(l)

(a)

(j)

Loading...

Loading...