www.SteamPoweredRadio.Com

INTERCONNECTING

Re

ga

rdless

of

application observe

the

re

quir

ements

und

er "Line

Input"

and "Reproduce

Output"

when

interconnec

ting

the

machine with

an

y

other piece

of

equipment.

3-2

CONNECTORS

A power cable and marching plugs for the

MICROPHONE

(JI

01S

),

LINE

INPUT

(]10

2S),

and

OUTPUT

(JI

04S)

connectors

are

s

up

-

plied

with

the

equipment.

Shielded, low-capacity cable is re

comme

nded for

making

up

input

and

output

cables. Make such cables as shore as possible for intercon-

ne

c

ting

units in

audio

systems.

Refer

co

the

schematic diagram ( Fig.

5.3),

to

determin

e correct

pin

conn

ec

ti

on for all plugs.

STUDIO

The

reproduce head

cab

le is d

ou

ble shielded, insuring against r-f

INSTALLATION

pi

ckup. Cable capacity and length have been minimized

co

avo

id

high

frequency loss. In general, mo

unt

the

electro

ni

c assembly and cape trans-

port

no mo

re

than

o

ne

foot apart.

If

che r

epro

du

ce head cable is len

gt

h-

ened for gr

ea

ter separation of

the

components, high fre

qu

ency response

wi

ll

be

affected. In the

eve

nt an in

sta

llation absolutely d

ema

nds len

gth-

ening

thi

s cable, a very low capacity rype (

RG

-62/

U)

is

in

dicated, plus

the

addition

of

an

ourer shield.

Hi

gh fr

eq

uen

cy

losses cannot be ke

pt

co

a

minimum

if

the

cable l

ength

exceeds three feet.

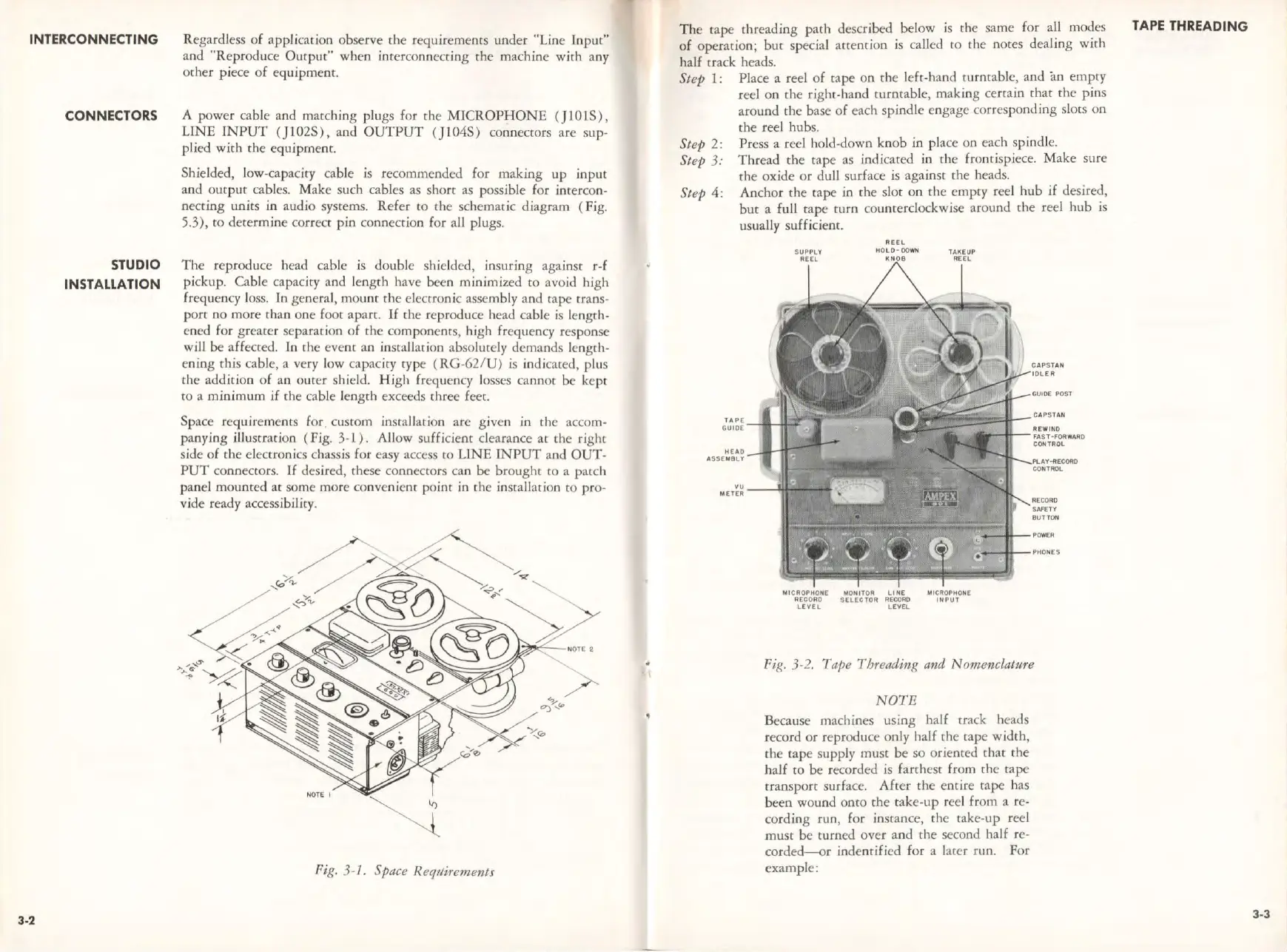

Space requirements for custom installation

are

given in the accom-

panyin

g illu

st

rati

on ( Fig.

3-

1

).

All

ow

suffi

cient

clearance

at

the

right

side

of

the electronics chassis for easy access

to

LINE

INPUT

and

OUT

-

PUT

co

nn

ecto

rs.

If

desired, these conneccors can

be

brought

co

a parch

pane

l

mounted

at

some

more convenie

nt

point in

the

inscallacion ro

pr

o-

vide ready accessibility.

Fig.

3-

1. Space R

eq1

ti

rcments

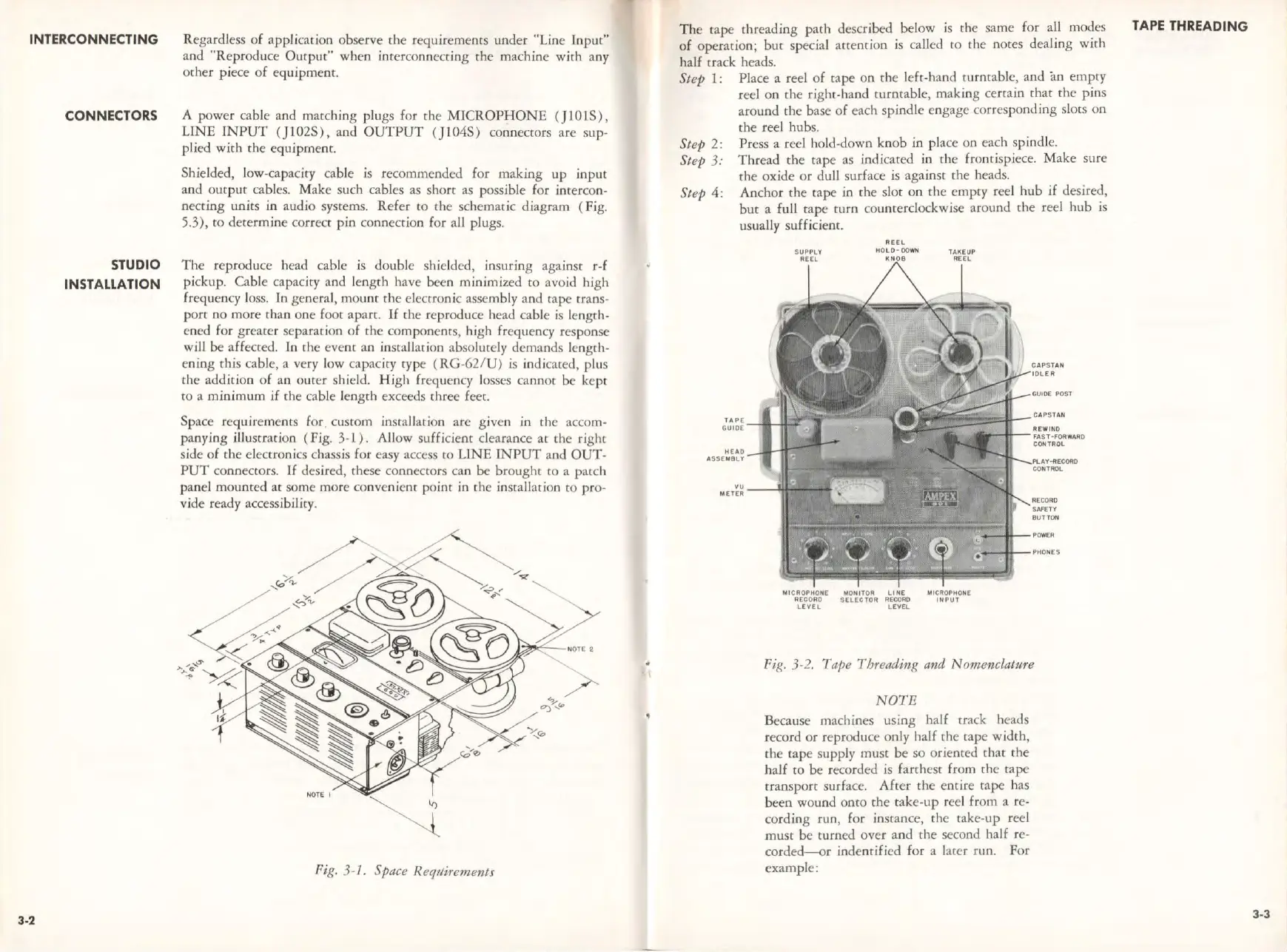

Th

e cape threading

path

described bel

ow

is

the

same for all modes

of operation; but special attention is ca

ll

ed

to

the

notes dealing

with

half crack heads.

St

ep

1: Place a r

ee

l of cape on

the

left-hand

cu

rnrable, and iui

empty

ree

l

on

the

ri

gh

t-hand

turnt

able,

making

certain

tha

t

the

pins

around rhe base of each

sp

indle en

gage

cor

responding s

loe

s

on

the

reel

hub

s.

Step 2:

St

ep

3:

Press a reel hold-down

knob

in place on each spi

ndle

.

Thr

ead

the

cape as indicated in

th

e fro

nti

spiece.

Mak

e sure

the

ox

i

de

or dull surface is against

th

e heads.

Step

4:

Anchor

the

rape in rhe slot

on

the

em

pry r

ee

l

hub

if desired,

but

a

full

cape

turn

councerclockwise around che reel

hub

is

usua

ll

y sufficient.

HEAD

ASSEMBLY

REEL

MI

CROPHO

NE

MONITOR

LINE

MI

CROPHO

NE

RECORD

SELECTOR

RECORD

INPUT

LEVEL

LEYEL

CAPSTAN

IDLER

GUIDE

POST

CAPSTA

N

R

EWIND

FAST·FORWARD

CONTROL

Pl.AY-RECOAO

CO

N

TROL

RECORD

SAFETY

BUTTON

Fig.

3-2

.

Tap

e Threading

and

N omenclatNre

NOTE

Because machines using half track heads

record

or

reproduce only half

the

cape wi

dth,

the

t

ape

supp

ly

must

be

so

oriented chat

th

e

half

to

be

recorded is farthest from

th

e cape

transp

ort

surface.

After

the

e

ntir

e rape has

been wound onto che take

-up

reel from a re-

cording

run, for instance,

the

take-

up

r

ee

l

muse

be

turned over a

nd

the

second half re-

corded--or

indencifi

ed

for a lacer

run.

For

ex

ample:

TAPE THREADING

3-3

Loading...

Loading...