www.SteamPoweredRadio.Com

4

-4

ROUTINE

MAINTENANCE

Cleaning

Lubricati

on

Routine maintenance

of

the

cape transport mechanism consists pri-

marily

of

periodic cleaning and lubrication.

Cleanliness

of

all

parts

of

the tape drive mechanism

is

required

for

con-

sistent

optimum

performance. Mose tape manufacturers lubricate the

ir

tapes; chis lubricant will gradually form a coating

on

the head assembly

and

the

idler wheels

and

may cause loss

of

positive drive at the capstan.

Therefore, periodic cleaning

of

both the head assembly and

al

l

parts

of

the

tape drive mechanism

is

particularly important.

The

recommended

agent

for cleaning

Ampex

Head

Assemblies is a mixture

of

Xylene

and

0.1% Aerosol.

This

agent

is available in 2

oz.

bottles.

(Ampex

Catalog

No.

FP-7.)

To

clean any head assembly simply wind a clean, lintless

cloth on a swab-stick

and

moisten with chis mixture. Swab

the

heads

periodically

to

remove all dirr and oxide which may have accumulated

f~om

the

tape. Clean all pares except the head assembly with a clean,

lmtless cloth moistened with denatured alcohol.

CAUTION

Do

noc

use any ocher solv

ents

as there are some which may damage the

adhesive used

to

hold the head laminations together.

The

recommended standard lubricant for the four places which re-

quire periodic lubrication

(motor

and capstan)

is

Caloil

No

. OC-11.

This

lubricant is available from

AMPEX

as Stock

No.

T0-9

( ½ oz.

oiler)

or

FP-5

( 4 oz.)

NOTE

The

proper

lubricant is available from

AMPEX

as Stock

No.

T0

-9

(

Vi

oz.

oiler)

or

FP

-5

(4

oz.).

The

upper

and l

ower

bearings

of

the drive mocor should be lubricated

after every

500

h

ours

of

operation.

The

upper

oil hole

of

the motor

is

accessible through a hole in the tape transport

gri

ll

e slighcly above

and

to

the

left

of

the takeup turntable. For access to the lower oil hole, lo-

cated in the side

of

rhe moror end bell, remove rhe tape transport from

the case ( See Fig.

4-2).

Four

or

five drops

of

one

of

the recommended lubricants is sufficient.

Care should be taken

to

avoid over-oiling

or

sp

ill

s.

Any such excess

should

be

wiped away

with

solvent.

The

capstan may require oiling

about

once for every four oilings

of

rhe

drive motor.

For

access

co

the

upper

bearing, the capstan idler muse

first

be

removed ( See Fig.

4-2)

. Remove the rubber cap

on

the idler.

Remove the hairpin retainer

and

lift

the

idler off its shaft, caking care

not

to

lose the washers associated

with

ir.

The

aluminum

plug-boccom

over the capstan shaft may

now

be pried off and the felt washer beneath

it

removed

co

expose the

upper

capstan bearing.

Use

as

much

of

one

of

the

recommended lubricants as the bearing will accept,

wipe

away

any excess,

and

reassemble.

CAUTION

Do

not

oil

the

felt washer which serves only as a dust protector

and

to

keep

oil from working its way

up

the capstan.

For access

to

the

lower bearing, remove the tape transport from the case.

The

oil hole

is

located in the bearing housi

ng

as shown in Fig. 4-2.

Ure exactly f ottr drop1

of

oil

--

no

more.

Do

not

o

il

any ocher

parts

of

the

tape

transport mechanism. All

other

bearings and moving pares are lubricated for life.

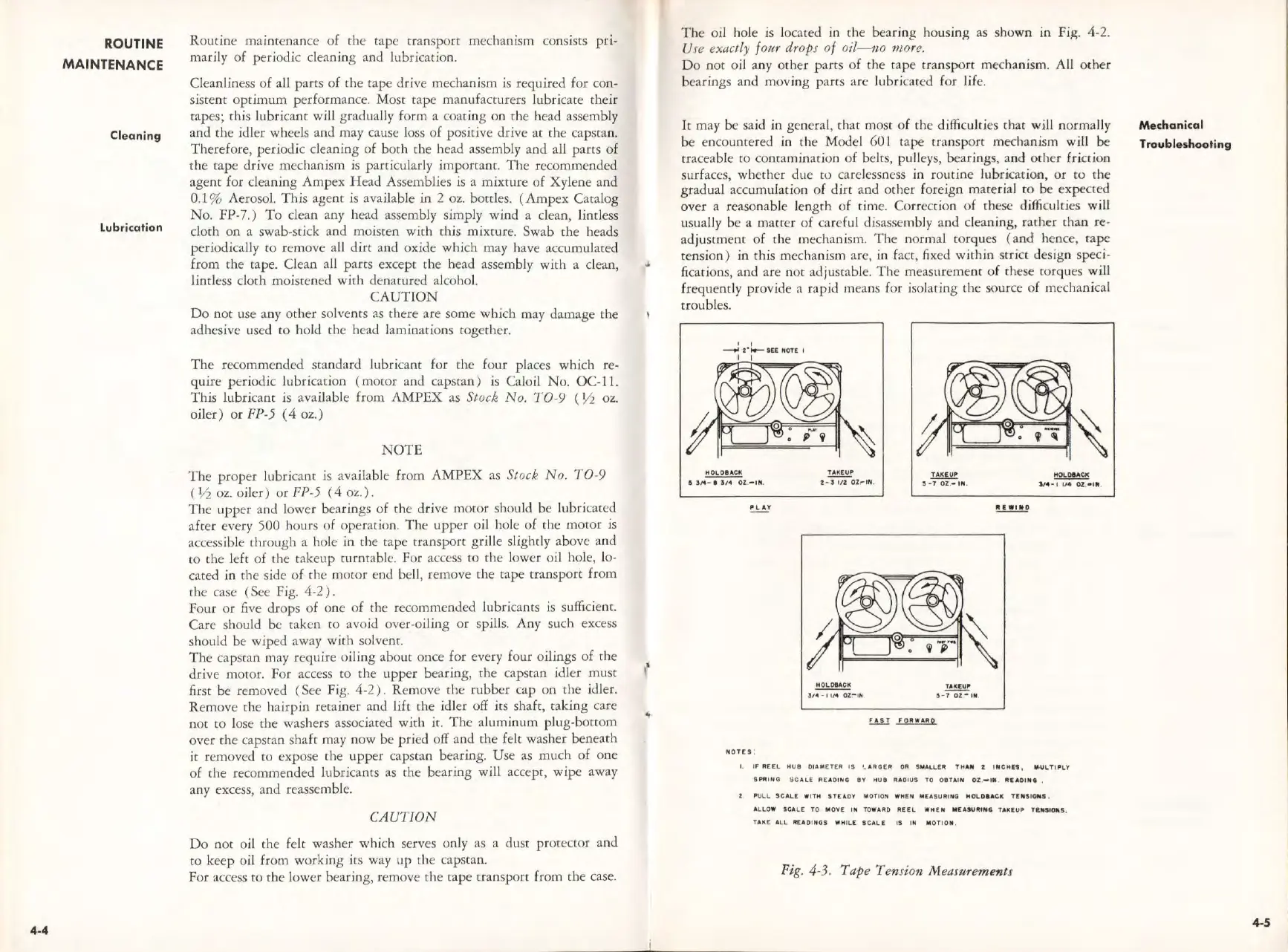

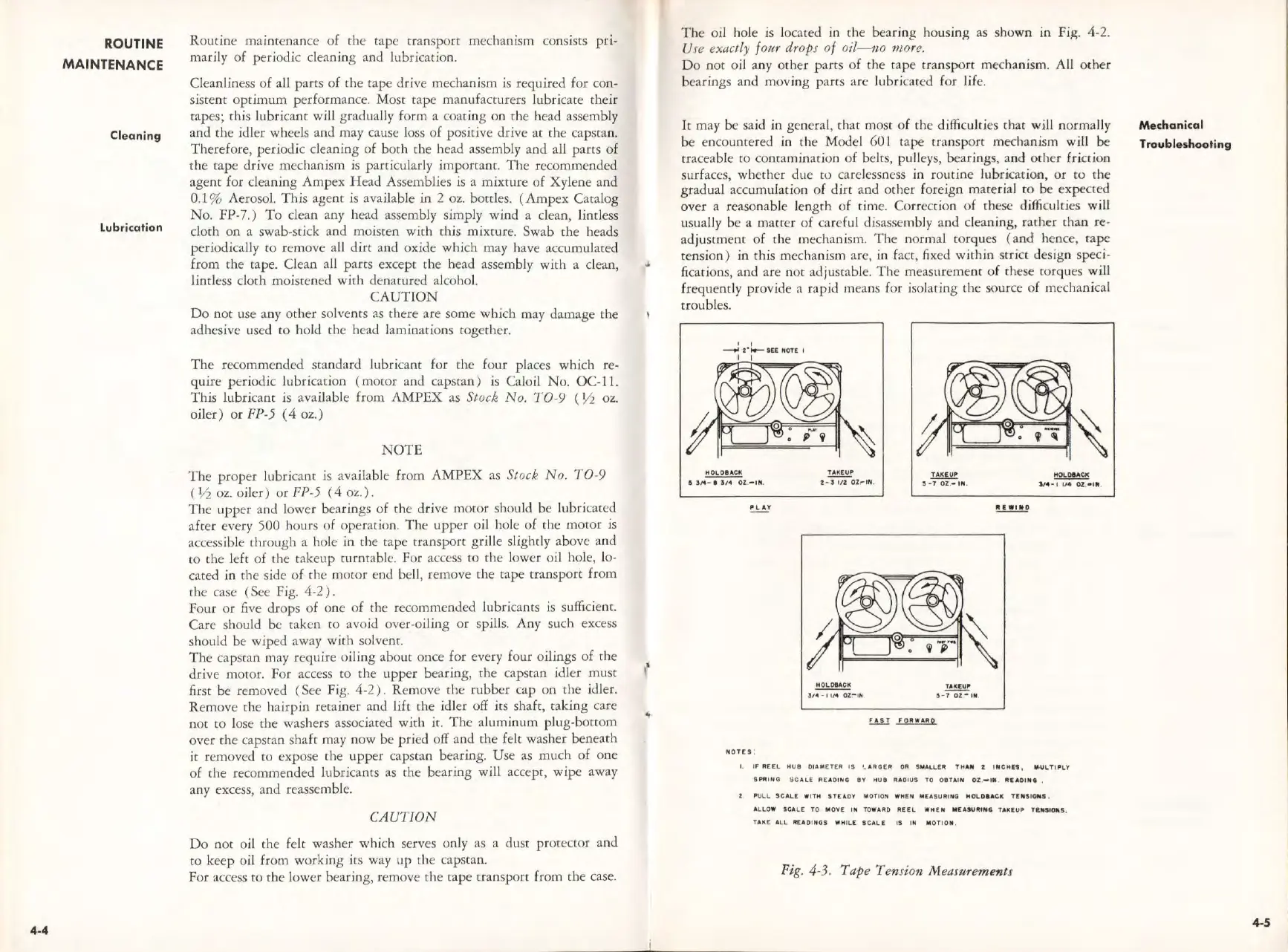

le may be said

in

ge

neral, chat most of the difficulcies char will normally

be

encou

nt

ered

in

the

Model 601 tape transport mecha

ni

sm will

be

traceable

to

contamination

of

belcs, pulleys, bearings, a

nd

ocher friction

surfaces,

whether

due

to

carelessness in routine lubrication,

or

to

rhe

gradua

l accumulation of d

irt

a

nd

other foreign

ma

terial

to

be

expected

over a reasonable l

ength

of time. Correction

of

these difficulties will

usually be a macrer

of

careful disassembly and cleaning, rather

than

re-

adjustment of

the

mechanism.

Th

e normal torques ( and hence, rape

tensi

on)

in

this mechanism are,

in

fact, fixed within strict design speci-

fi

cations, and are noc adjustabl

e.

The

measurement

of

these

to

rques will

frequently provide a

rap

id means for isolati

ng

the source

of

mechanical

troubles.

~

~

~

,,...

_ I

3/4

OZ

-IN

,

2-3

112

OZ~IN

.

T

AKE

U"'

s-~

1

111

.

HOLNACK

114

-~ • l

fl

.

NO

TES

HOLOBACK

3/ 4 - •

,,.

oz-

1N

TAK[U"'

5 - 7

oz.-1N

,

I.

IF

ftEEl

HUB

DIAMETER

IS

•. AAOER Oft SMALLEIIII

THAM

2 UICHIES,

111-

ULTlflLY

SPl'tl

N

(J

!SCALE

lltEAO\frtO ev

HUS

ftADIUS

TO

O

BTA

IN oz.- ,.

JtfAD

INI .

2:

P'UlL

SCALE: W

ITH

STEADY

MOTION WHEN

MEA

SUftl

NG

HO\.DIACK

T!NSIGJU'

.

ALLO

W

SCALE

TO

MOVE

IN TOWARD

REEL

WH

E N M

EAS~.umu•

TAICIEUI' T

IJitSION.S

.

TAKE A

LL

READINGS

WHI

LE

SC

A

LE

IS

IN

M

OTION.

Fig.

4-3. Tape Tension Measurements

Mecha

nical

Troubleshooting

4-5

Loading...

Loading...