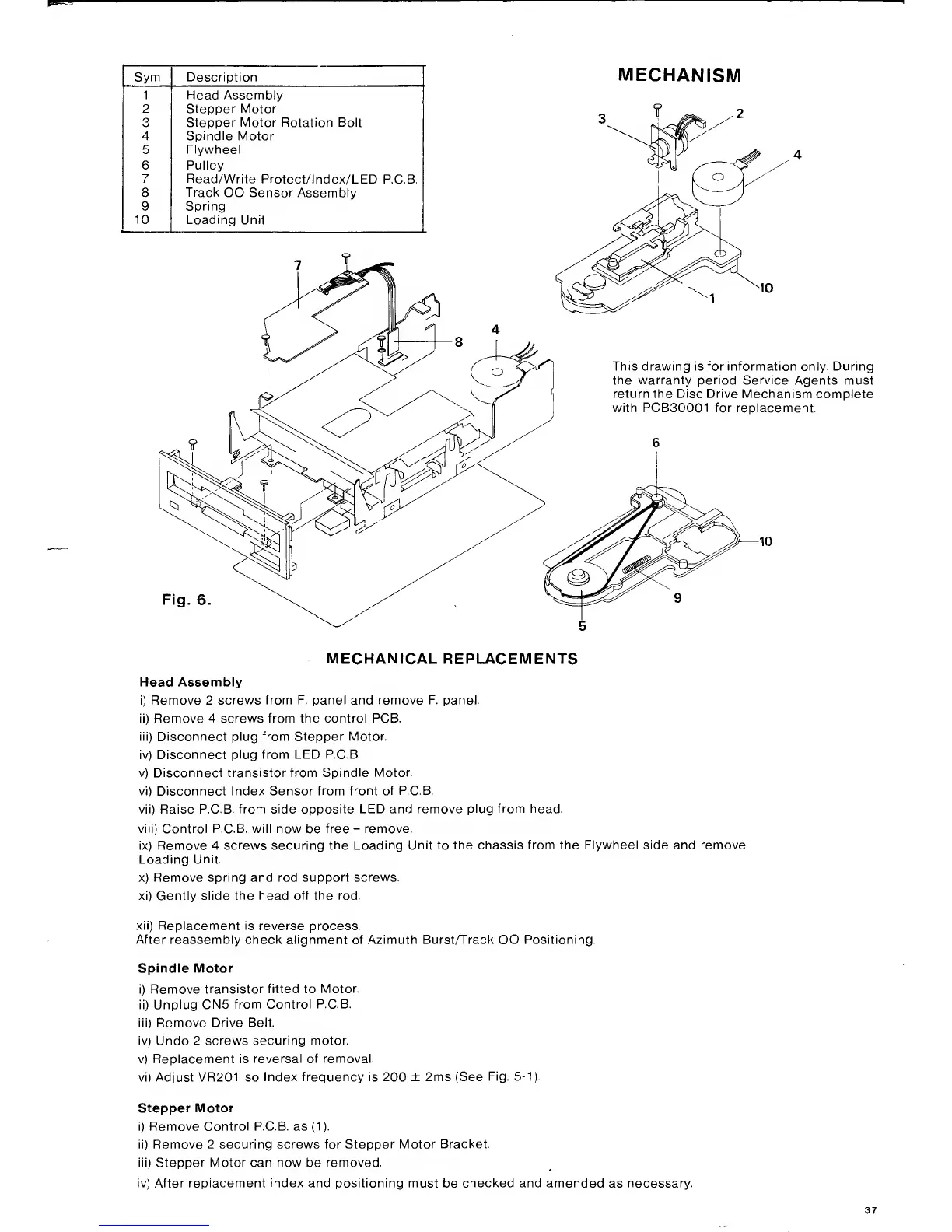

Sym Description

1 Head Assembly

2 Stepper Motor

O

Stepper Motor Rotation Bolt

4

Spindle

Motor

5

Flywheel

6 Pulley

7 Read/Write

Protect/lndex/LED

P.C.B.

8

Track

OO Sensor Assembly

9

Spring

10 Loading Unit

MECHANISM

This drawing is for information only. During

the warranty period Service

Agents must

return the Disc Drive Mechanism complete

with PCB30001 for replacement.

Fig.

6

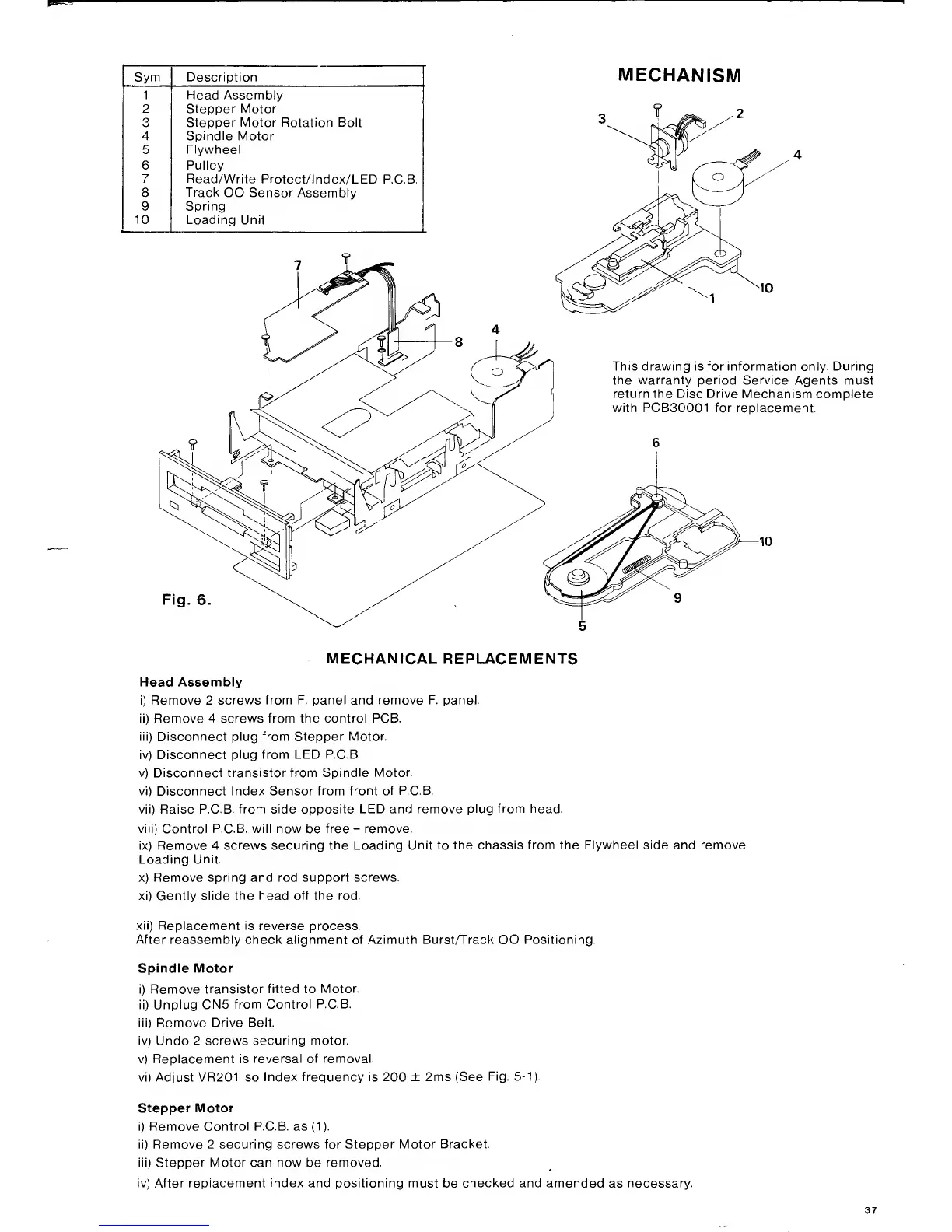

MECHANICAL REPLACEMENTS

Head Assembly

Remove 2

screws from F. panel and remove F. panel.

i)

Remove 4 screws from the control PCB.

ii) Disconnect plug from Stepper Motor.

v)

Disconnect plug from LED P.C.B.

v) Disconnect transistor from

Spindle Motor.

vi) Disconnect Index Sensor

from front of P.C.B.

vii)

Raise P.C.B.

from side opposite LED and remove

plug from head.

viii) Control P.C.B. will now

be

free

-

remove.

ix) Remove 4 screws securing

the Loading Unit to the

chassis from the Flywheel side and remove

Loading

Unit.

x) Remove spring and rod

support screws.

xi) Gently slide

the head off the rod.

xii) Replacement is

reverse process.

After

reassembly check alignment of Azimuth Burst/Track OO Positioning.

Spindle Motor

)

Remove

transistor fitted to

Motor,

i) Unplug

CN5

from Control P.C.B.

ii) Remove Drive

Belt,

v)

Undo

2 screws securing

motor,

v) Replacement is

reversal of removal,

vi) Adjust VR201 so

Index frequency is 200 ± 2ms (See

Fig,

5-1).

Stepper Motor

)

Remove Control P.C.B. as

(1).

i) Remove 2 securing screws for

Stepper Motor Bracket.

ii) Stepper Motor can now

be

removed.

v) After replacement

index

and positioning must

be

checked and amended

as

necessary.

Loading...

Loading...