4

1. Transport & handling

1.1 Transport

E 308 Industrial grinding machine is delivered mounted to a pallet wrapped in protective

packing.

1.2 Handling

E 308 industrial grinding machine can easily be transported in the packing in which it is

delivered. If the grinding machine is delivered on a pedestal you must make sure that the

pedestal is secured to the transport pallet.

1.3 Placing

Placing of the industrial grinding machine must take place on a firm and level surface.

Now tighten the grinding machine to the floor or the working table by using the four bolt

holes used for securing the machine to the pallet.

The electrical voltage must be within the given ranges shown on the motor label.

The machine must be wired according to the wiring diagram (please see section 7.3).

The wiring must be performed by an authorised installer. Please make sure that the motor

has the correct direction of rotation (please see the arrow on the cover).

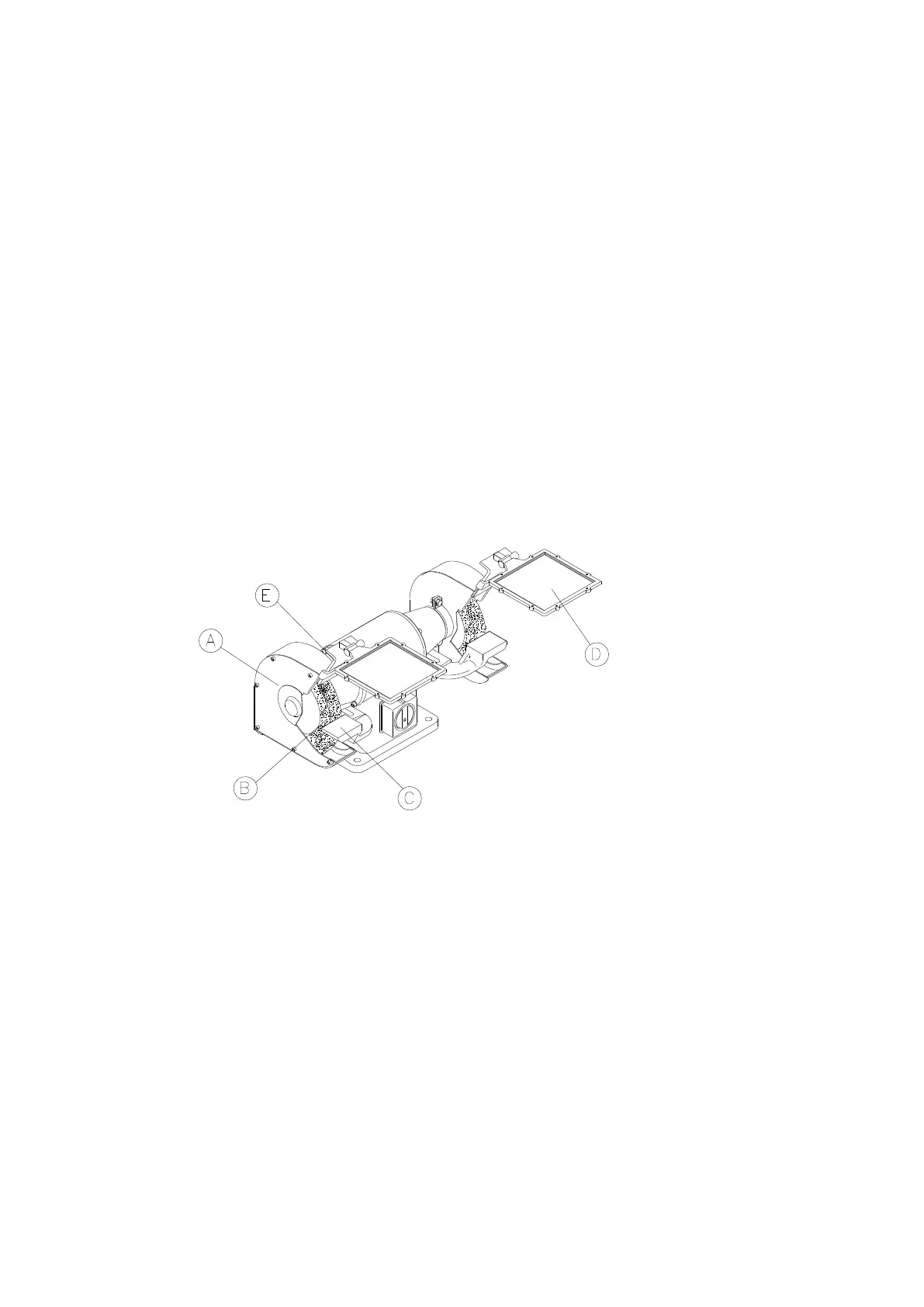

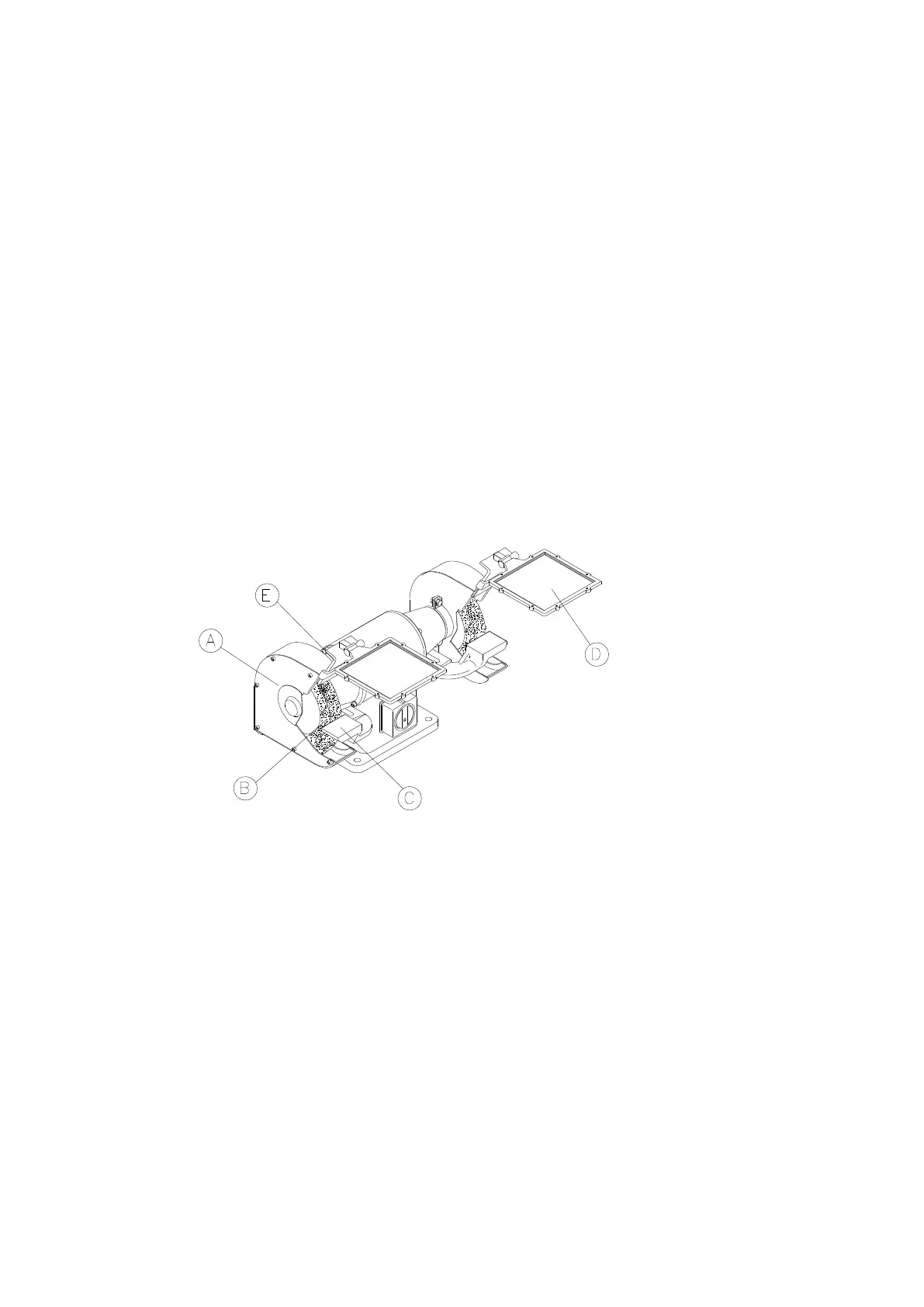

Fig.: 1.1

Before operating the machine please control that the outer cover (A) (see fig.: 1.1) is

secured to the inner cover. The outer cover must be mounted during use of the machine

and can only be dismounted during maintenance. The grinding wheel (B) must be able to

rotate freely without being loose. The tool rest (C) must be adjusted to a distance of appr.

2mm from the grinding wheel.

The eye shield (D) must be kept clean and adjusted to the correct position and the spark

arrester (E) must also be adjusted to a distance of 5mm from the grinding wheel and

lightly fastened.

All these checks and adjustments can only be made while the machine is disconnected

from the power source. First time you start up the machine please let it run at maximum

speed for appr. 5 minutes before start grinding. Make sure you are positioned in a safe

distance while doing the running test.

Loading...

Loading...