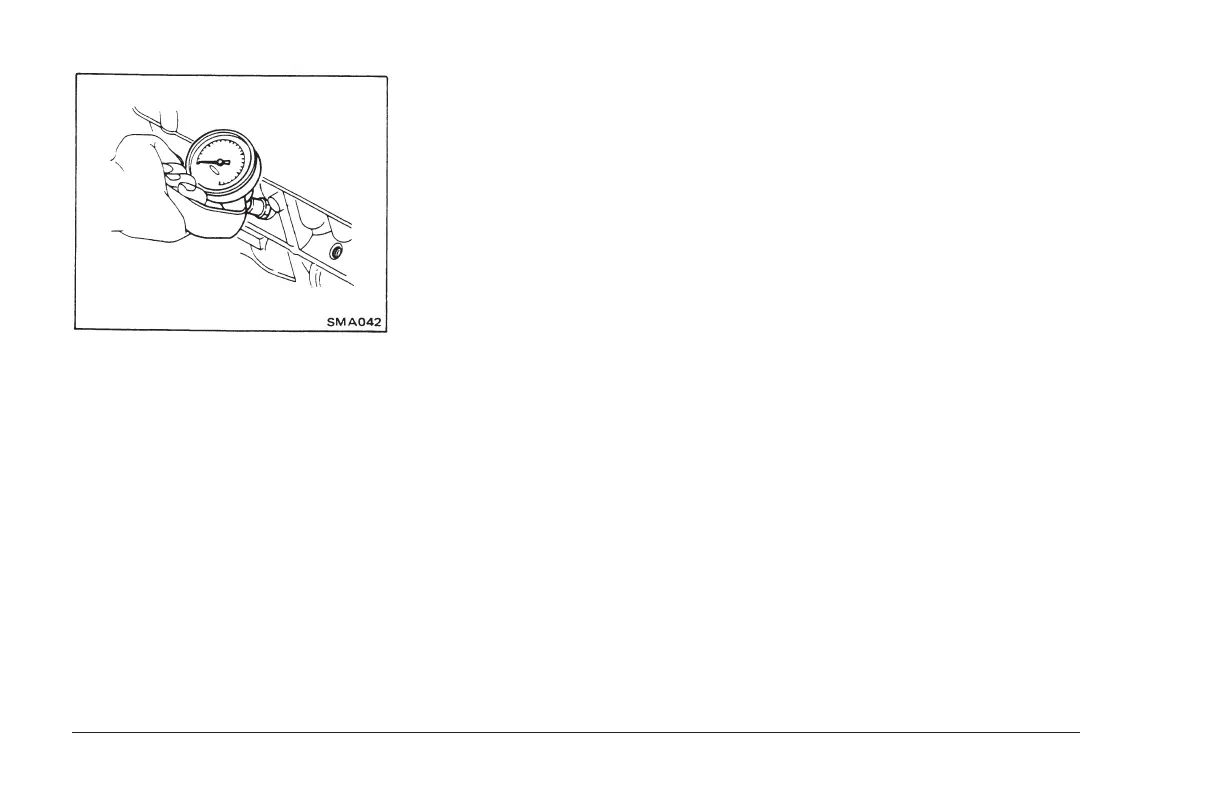

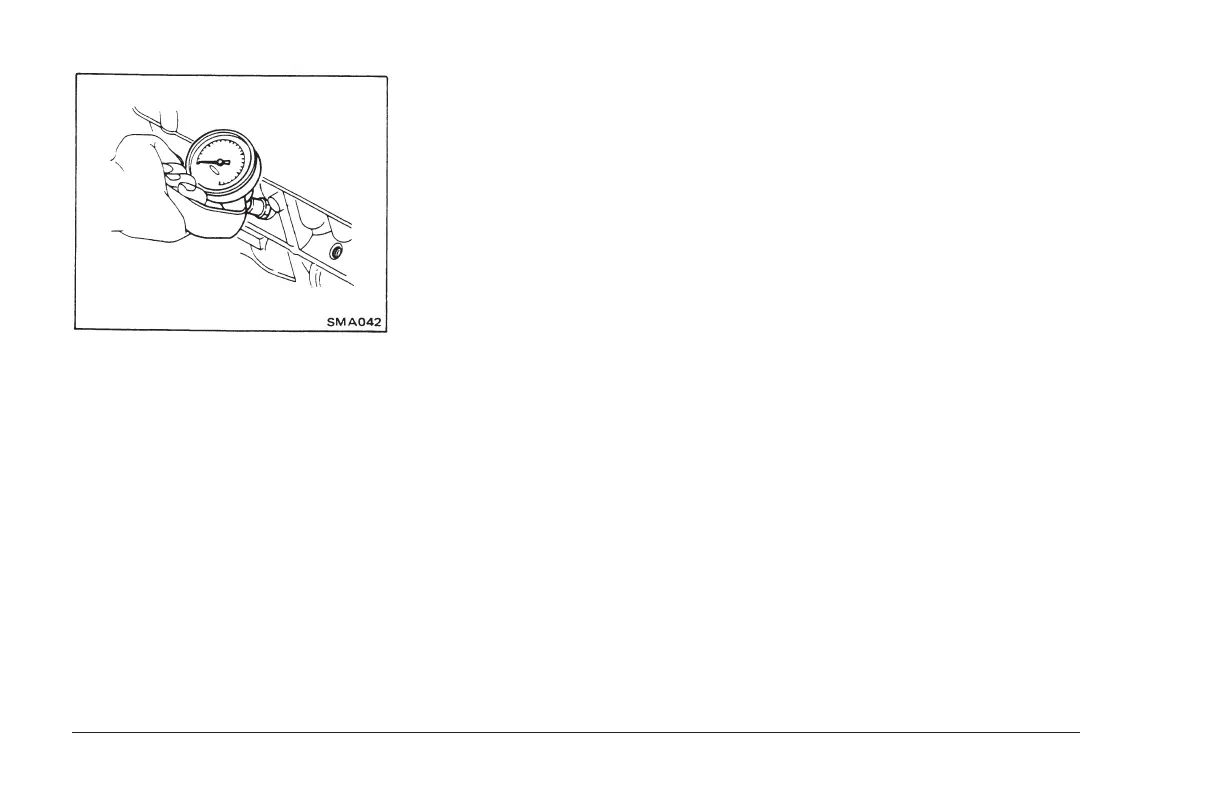

Checking engine compression

pressure

1. Warm up engine sufficiently, then stop

engine.

2. Remove all spark plugs.

3. Properly attach a compression tester to

spark plug hole in cylinder being tested.

4. Set carburetor throttle valve at fully-open

position.

5. Crank engine and read gauge indiction.

Engine compression measurement should

be made as quickly as possible.

Compression pressure:

Standard

1,275 kPa (12.75 bar,

13.0 kg/cm

2

,

185 psi)/300 rpm

Minimum

1,079 kPa (10.79 bar,

110.0 kg/cm

2

,

158 psi)/300 rpm

6. Cylinder compression in cylinders should

not be less than 80% of the highest read-

ing.

If cylinder compression in one or more cylin-

ders is low, pour a small quantity of engine oil

into cylinders through the spark plug holes

and retest compression.

If adding oil helps the compression pres-

sure, chances are that piston rings are worn

or damaged

If pressure stays low, valve may be sticking

or sealing improperly

If cylinder compression in any two adjacent

cylinders is low, and if adding oil does not

help the compression, there is leakage past

the gasketed surface.

Oil and water in combustion chambers can

result from this problem.

Checking fuel lines (Hoses,

piping, connections, etc.)

Check fuel lines for proper attachment, leaks,

cracks, damage, loose connections, chaffing

and deterioration. If necessary, replace any

damaged or defective parts.

18

Loading...

Loading...