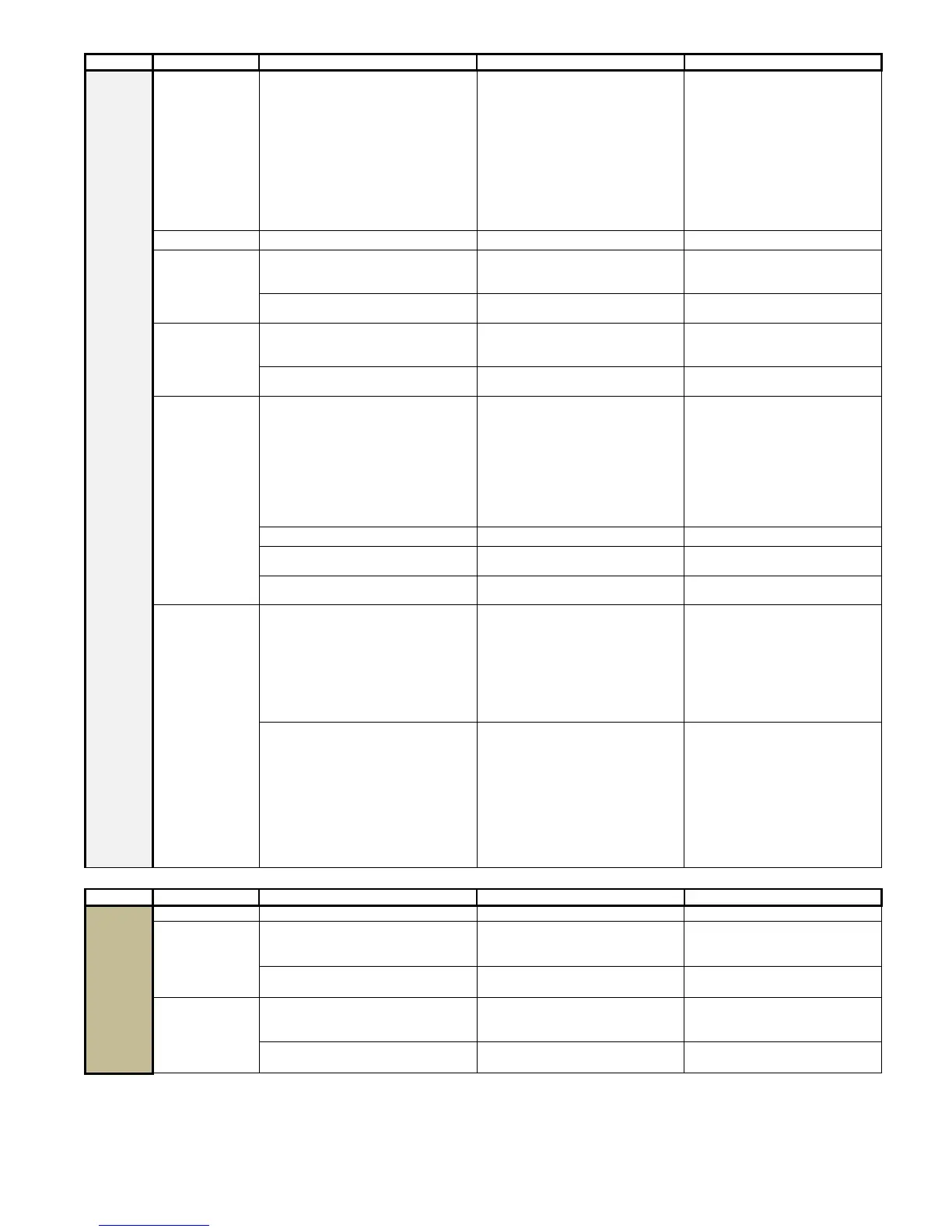

H3

gas R134a gas is missing

Check the refrigerant connection

between units and the circuit of

the external unit using a leak

detector.

• Check that the pressure inside the

circuit have to be more than 3 bar

(using “service” connector on the

external unit)

• For more accurate measure, do

the * LOW GAS CHECKING at the

end of this paragraph

Make a gas recharge and check the

refrigerant connection between units

and the circuit of the external unit

using a leak detector.

If a component is faulty, replace it.

Empty the circuit, make the vacuum

and a new charge in accordance with

the quantity indicated on the external

unit technical label.

evaporator due to ice, leafs, dirt → clogged Visual check of the component Clean the component

air sensor

faulty component → out of tune

Verify with a tester that

between terminals is compliant with

the “SENSOR TEST TABLE”

If the component is faulty, replace it

incorrect positioning Verify the proper positioning

Place the component in the right

position

evaporator sensor

faulty component → out of tune

Verify with a tester that the resistance

between terminals is compliant with

the “SENSOR TEST TABLE”

If the component is faulty, replace it

incorrect positioning Verify the proper positioning

Place the component in the right

position

4-way valve

faulty component → break

Check the functionality after a

temporary ON/OFF power

disconnection

• Verify that the resistance between

terminals is not zero or infinite

• Verify that the resistance between

the terminals and the ground

connection of the terminal block is

infinitive

If the component is faulty, replace it

damaged wirings → not working Visual check of the component If the component is faulty, replace it

bad connection of wirings → not working

Check the correct connection with the

Place the component in the right

position

incorrect positioning Verify the proper positioning

Place the component in the right

• wear

• safety thermostat broken (short

circuit)

• inlet refrigerant in liquid phase due

to high quantity of refrigerant

• over pressure due to broken

pressure switch (short circuit)

• Check the functionality after a

temporary power disconnection

• Verify that the resistance between

terminals is in compliance with

the relative table value

• Verify that the resistance between

the terminals and the external

unit casing is not zero

If the component is faulty, replace it

Not working due to:

• pressure switch broken (open

circuit)

• damaged wirings

• bad connection of wirings

• motor capacitor broken

Pressure switch: verify with a

tester that the resistance between

terminals is infinite even if the

circuit pressure is ok

• Visual check of the wirings and

check the connection with the

mainboard

• Motor capacitor: verify with a

tester that the resistance between

terminals is not zero

If a component is faulty, replace it;

Make connections in the right way

Visual check of the component

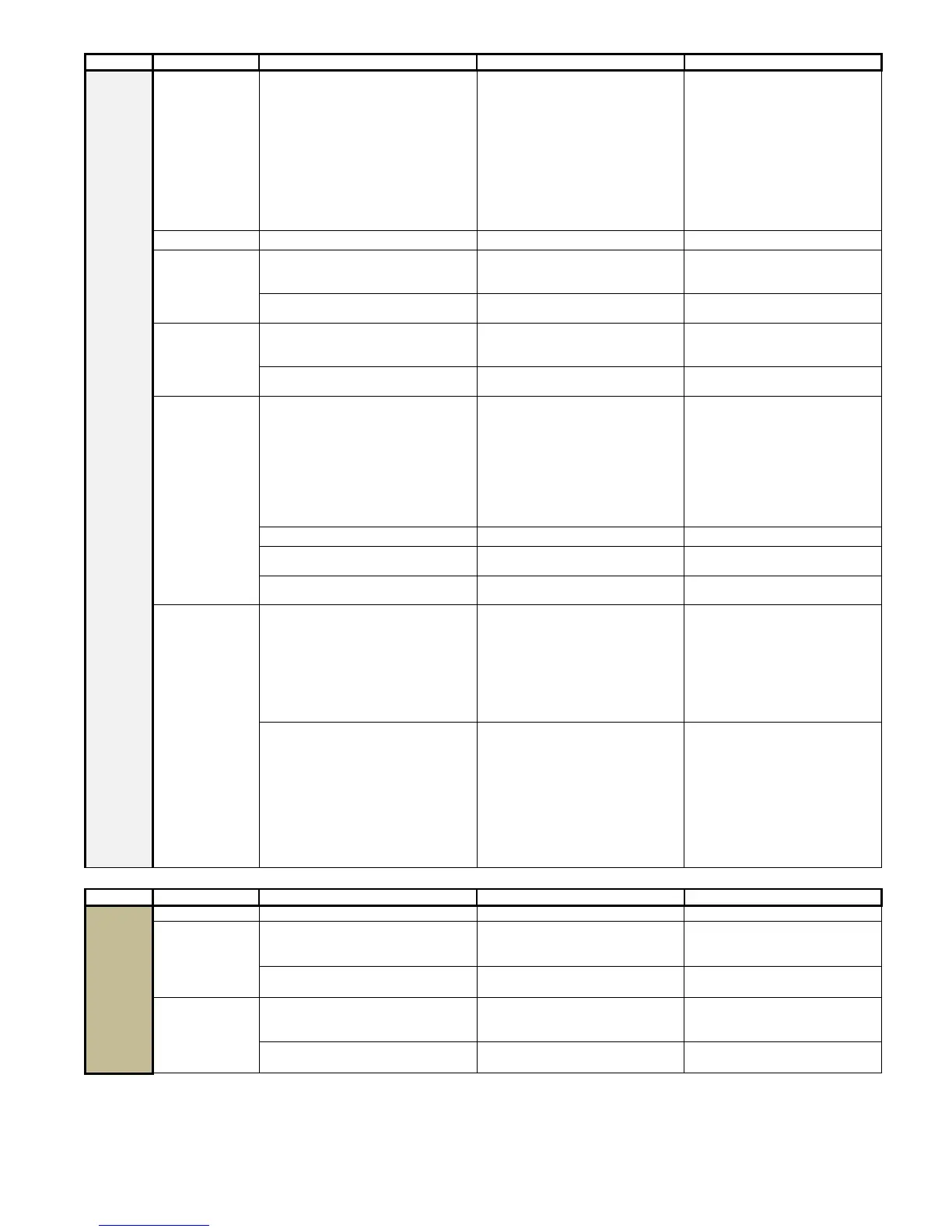

air sensor

faulty component → out of tune

Verify with a tester that the resistance

between terminals is compliant with

the “SENSOR TEST TABLE”

If the component is faulty, replace it

incorrect positioning Verify the proper positioning

the component in the right

position

evaporator sensor

faulty component → out of tune

Verify with a tester that the resistance

between terminals is compliant with

the “SENSOR TEST TABLE”

If the component is faulty, replace it

incorrect positioning Verify the proper positioning

Place the component in the right

Loading...

Loading...