40 /

TECHNICAL AREA

SERVICE CODE

Press th programming key b to select code 234 and press Ok

COMPLETE MENU

0 NETWORK

0. 2

BUS

NETWORK

0. 2.

0 Network Presence Boiler

Indication of the devices connected via BUS.

0. 4 BOILER USER INTERFACE

0. 4. 0 Zone to be set by display

from 1 to 3 (nr) 1

0. 4. 1 Backlight timing

from 1 to 10 minutes

or 24 hours

10

0. 4. 2 Thermoregulation button

deactivation

0 = OFF

1 = ON

0

2 BOILER PARAMETERS

2. 0 GENERAL

2. 0. 0

DHW Setpoint Temperature

from 36 to 60 (°C) 55

Setting by DHW button 2

2. 0. 1 DHW Pre-Heating

0 = OFF

1 = ON

0

2. 0. 2 Gas type

0 = Natural Gas

1 = LPG

2 = G230

3 = G130

0

2. 1 FREE PARAMETERS

2. 1. 4 Boiler circulator type

0 = Standard effi -

ciency

1 = High effi ciency

1

ONLY FOR SERVICE - To be used only in

substitution P.C.B.

2. 2 SETTINGS

2. 2. 0 Soft ignition from 0 to 100

see Table summarising changes

2. 2. 3 Underfl oor thermostat

or zone 2 ambient

thermostat selection

0 = Floor safety

thermostat

1 = Zone 2 ambient

thermostat

0

2. 2. 4 Termoregulation 0 = Absent

1 = Present

0

Termoregulation can be activated by pressing the

AUTO button.

2. 2. 5 Heating ignition delay 0 = Deactivated

1 = 10 seconds

2 = 90 seconds

3 = 210 seconds

0

2. 2. 8 Boiler version

- NOT TO MODIFY

from 0 to 5

0 = Combi

0

ONLY FOR SERVICE - To be used only in

substitution P.C.B.

2. 2. 9

Boiler nominal power (kW)

ONLY FOR SERVICE - To be used only in

substitution P.C.B.

2. 3 CENTRAL HEATING 1

2. 3. 0 < Not Available>

2. 3. 1 Maximum CH Adjustable from 0 to 100

(%)

60

see Table summarising changes

WARNING!!

THE AUTOMATIC CALIBRATION MUST BE DONE IN

CASE OF:

- REPLACEMENT OF: FAN, GAS VALVE, AIR/GAS

MIXER, BURNER, ELECTRODE.

- REPLACEMENT OF P.C.B.

- GAS CHANGEOVER

- ANY MODIFICATION TO THE FOLLOWING

PARAMETERS

220 - SOFT IGNITION

231 - MAX CH ADJUSTABLE

232 - MAX DHW PERCENTAGE

233 - MIN PERCENTAGE

234 - MAX CH PERCENTAGE

menu

sub-menu

parameter

description value

default

setings

menu

sub-menu

parameter

description value

default

setings

2. 3. 2 D.H.W. Maximum power

percentage

from 0 to 100 (%)

RESERVED FOR TECHNICAL ASSISTANCE Only if the

gas or PCB is changed - see Table summarising changes

2. 3. 3 Minimum power

percentage

from 0 to 100 (%)

RESERVED FOR TECHNICAL ASSISTANCE Only if the

gas or PCB is changed - see Table summarising changes

2. 3. 4 C. Heating Maximum

power percentage

from 0 to 100 (%)

RESERVED FOR TECHNICAL ASSISTANCE Only if the

gas or PCB is changed - see Table summarising changes

2. 3. 5 CH Anti-cycling time

mode

0 = Manual

1 = Automatic

1

2. 3. 6 Anti-cycling time

(If 235 = 0)

from 0 to 7

(minutes)

3

2. 3. 7 Cl H pump overrun

from 0 to 15 (minutes)

or 16 = continuos

3

2. 3. 8 Pump speed control - NOT ACTIVE

2. 3. 9 Delta T Pump Set - NOT ACTIVE

2. 4 CENTRAL HEATING PARAMETER 2

2. 4. 0 < Not A

vailable>

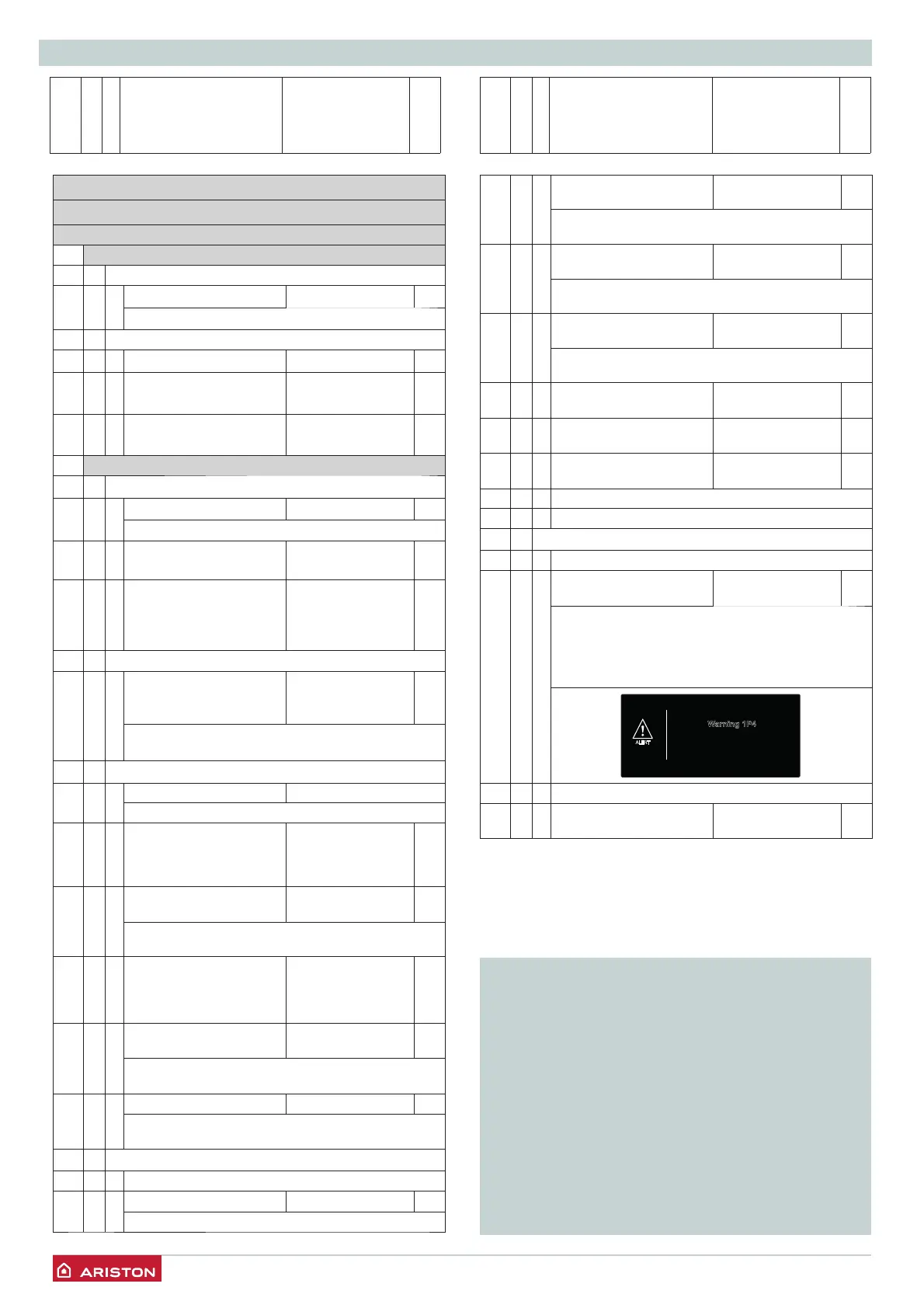

2. 4. 1 Warning Pressure from 4 to 8

(0,x bar)

6

if the pressure falls down to the pre-set alert value,

the boiler will signal a malfunction warning (

1P4)

for insuffi cient circulation; the request for re-

establishing the correct value will appear on the

display.

Warning 1P4

Filling Needed

ALERT

2. 4. 2 < Not Available>

2. 4. 3 Post-ventilation CH 0 = OFF

1 = ON

0

Loading...

Loading...