It is recommended that the following inspections be

carried out on the boiler at least once a y

ear:

1 - Check the seals for the water connections; replace

any faulty seals.

2 - Check the gas seals; replace any faulty gas seals.

3 - Visual check of the entire unit.

4 -

Visual check of the combustion process or analysis

of combustion by-products (see

SECTION 3.4) and

cleaning of the burner if needed.

5 - If necessary, dismantling and cleaning of the

combustion chamber.

6 - If necessary, dismantling and cleaning of the burner

jets.

7 - Visual check of the primary heat exchanger:

- check for overheating in the blade assembly;

- clean the exhaust fan if needed.

8 - Adjustment of the gas pressure, gas rate and soft-

light, partial load and full load.

9 - Check of the heating safety systems:

- safety device for maximum temperature (overheat

thermostat);

- safety device for maximum pressure (safety

valve).

10- Check of the gas safety systems:

- safety device for lack of gas or flame ionisation

(detection electrode).

11-

Check of the electrical connection (ensure it

complies with the instructions in the manual).

12- Check of Domestic Hot Water production efficiency

(flow rate and temperature)

13- General check of the combustion by-products of the

discharge/ventilation system.

14- Check of the general performance of the unit.

NOTE: THESE CHECKS ARE NOT EXHAUSTIVE

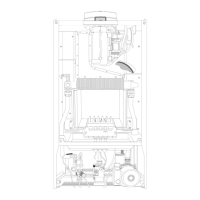

5. MAINTENANCE

Loading...

Loading...