14

preparing the boiler for operation

EN

Fault diagnostics guide

The Zone Manager Kit is protected against the risk of faults thanks to internal checks performed by

the board, which stops the system for safety reasons, if required.

The table below indicates the possible fault codes, their description and corresponding corrective

actions:

ERROR DESCRIPTION RECOMMENDED ACTIONS

7 0 1 Faulty Z1 delivery sensor

Check the connection of the relative probe.

Check the continuity of the probe.

Replace the probe if necessary.

7 0 2 Faulty Z2 delivery probe

7 0 3 Faulty Z3 ow probe

7 1 1 Faulty Z1 return probe

7 1 2 Faulty Z2 return probe

7 1 3 Faulty Z3 return probe

7 2 2 Zone 2 overheating

Check whether the shunt is present and whether

it is connected to terminal block “ST2” of the box,

or check the maximum heating temperature

adjustment for Zone 2 (parameter 525). Check the

connection of the safety thermostat on terminal

block “ST2” of the box.

7 2 3 Zone 3 overheating

Check whether the shunt is present and whether

it is connected to terminal block “ST3” of the box,

or check the maximum heating temperature

adjustment for Zone 2 (parameter 625). Check the

connection of the safety thermostat on terminal

block “ST3” of the box.

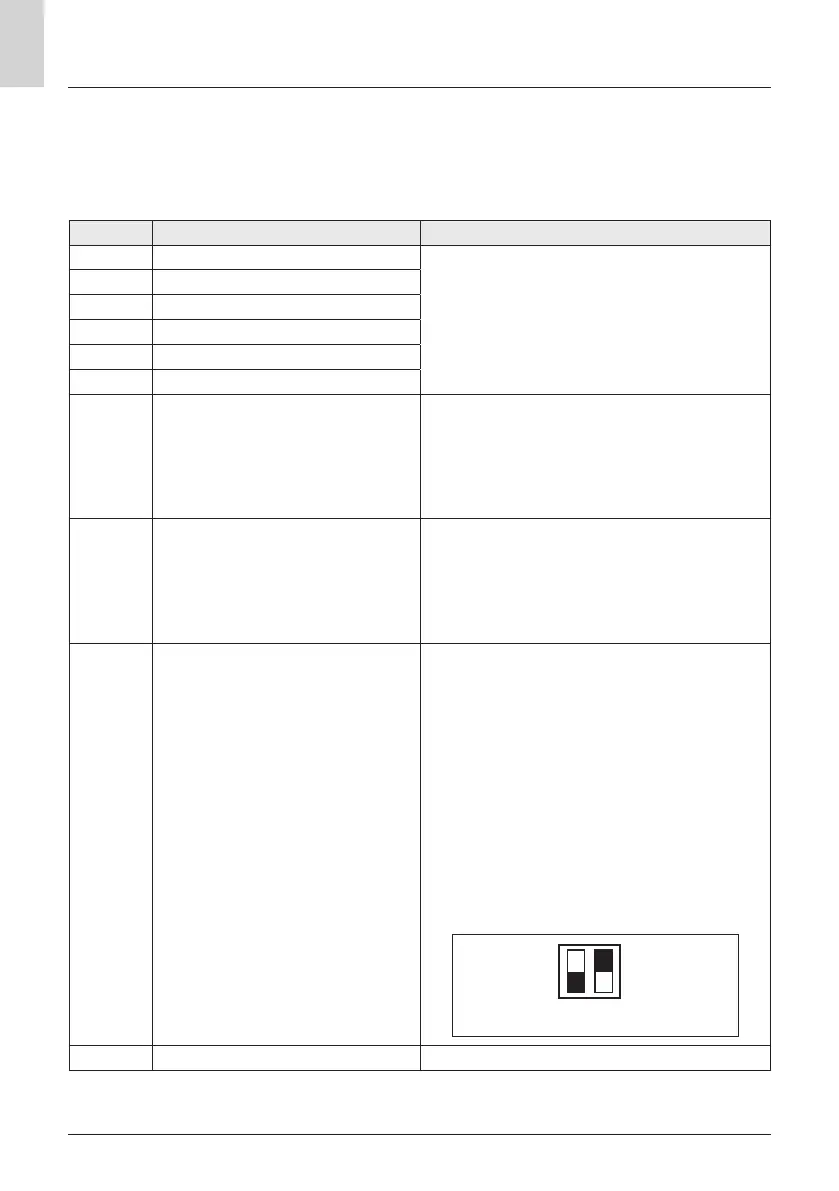

4 2 0

Power supply overload

BridgeNet® BUS

A BUS power supply overload error may occur due to

the connection of three or more devices within the

installed system.

Devices which may overload the BUS network in-

clude:

– Multi-zone module

– Energy Manager hybrid system or heat pump

– Solar pump assembly

– Module for instantaneous domestic hot water

production

To avoid overloading the BUS power supply,

set microswitch 1 on one of the PCBs inside the

equipment connected to the system (except the

boiler and energy manager) to OFF.

1

ON

OFF

2

microswitch

7 5 0 MZ hydraulic diagram not dened Refer to the “Programming” paragraph.

Temperature adjustment

For the temperature adjustment function consult the heating/cooling system installation manual.

Loading...

Loading...