5

Rate of feed

The rate at which the router is moved through the

material has a significant effect on the quality of the

cut and the length of service you will get from your

router and bits. Moving the router through the cut

too fast, as well as possibly overloading the tool and

damaging the bit, will cause the bit to take larger

pieces of material with each rotation, thereby causing

a rough, uneven cut. Moving the router through the

cut too slowly tends to cause burning of timber and

if excessive, will cause overheating of the bit.

The proper feed rate to use depends on the bit size,

the material being cut, the depth of cut and the speed

selected. With all these variables the surest way to

ensure that you get the best quality and efficiency of

cut is to practice on a scrap piece of the same

material to get a feel for what feed rate to use. This

will also show you exactly how the cut will look and

allow you to check your cutting depth.

Straight guide

1. The straight guide is used for chamfering, grooving

and straight cuts.

2. Always ensure that the straight guide is installed

on the right hand side in the feed direction

(Ref fig. 8).

3. To install, line up the holes in the tool base and

slide in the guide bars of the guide. Set the bit

and the straight guide at the desired position then

tighten the support screws.

4. When cutting ensure the straight guide sits flush

with the side of the workpiece. If the side of the

work piece is not straight the straight guide

cannot be used (fig. 9).

5. If the edge is too far away for the straight guide

to reach whilst still keeping the poles retained in

the base, or there is not a straight edge to follow,

a piece of wood or other straight material can be

clamped alongside where the cut is to be made.

The straight edges of the base can then be used

to guide the router instead of the straight guide.

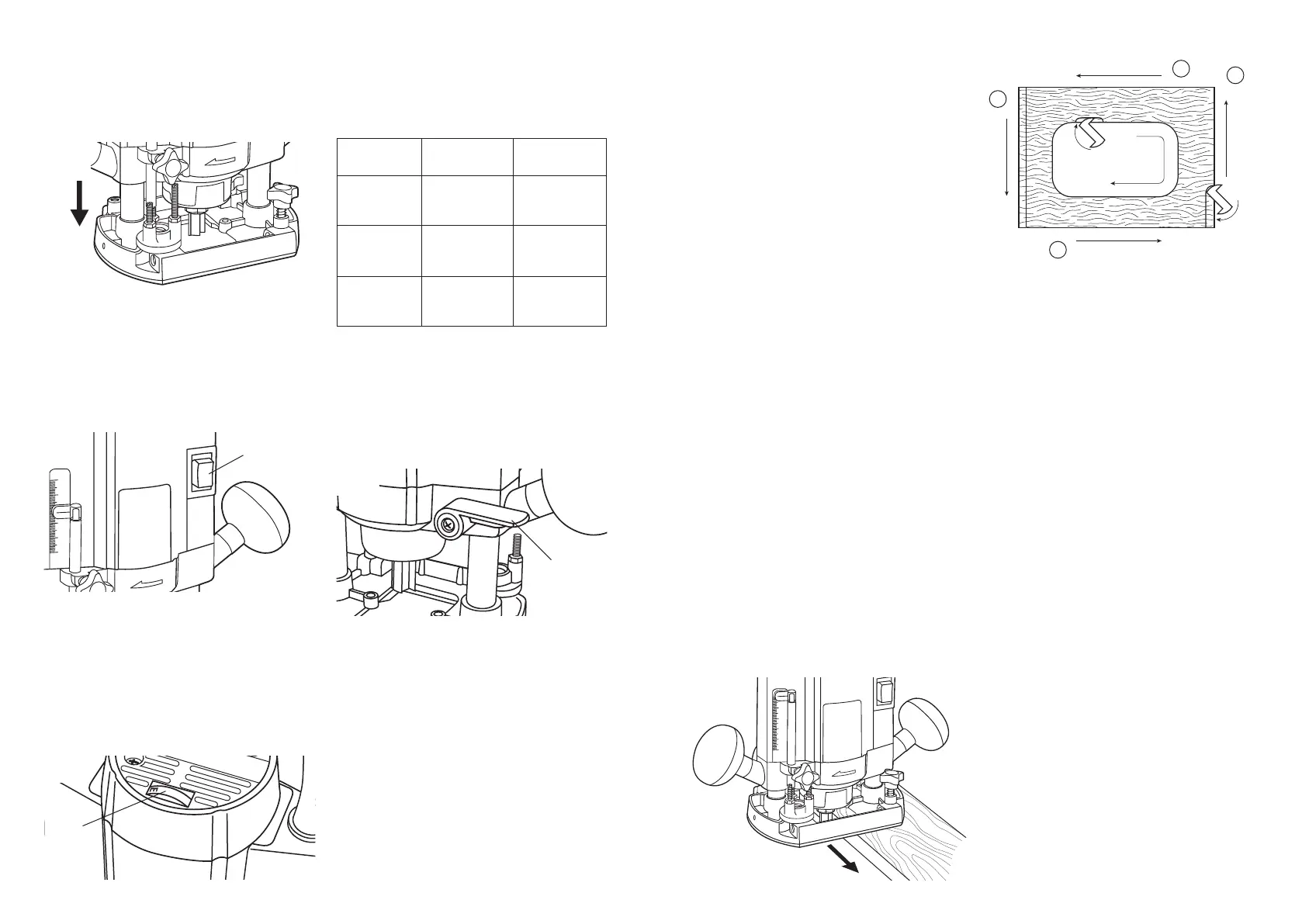

4

4. The stopper block has three adjusting positions.

You can easily obtain three different depths of

cut without adjusting the depth adjustment pole.

Starting the tool

1. To start the tool simply press in the operating

switch firmly during operation (fig. 4).

2. To stop the tool simply release the switch.

3. The following is a guide to suitable speed settings

for different applications. These are indicative

only, and will depend on the actual material and

cutter. It is advisable to make some test cuts on a

scrap piece of material before routing the actual

workpiece.

Variable speed control

1. The router is equipped with variable speed

control for greater flexibility of operation. It is

recommended that the speed dial be preset prior

to operation.

2. To adjust the speed simple turn the dial (fig. 5) until

the desired speed is reached (9,000 to 27,000 rpm).

’A’ indicates the lowest speed while ’G’ indicates

the highest speed.

Setting the depth of cut

1. Insert the required bit into the router as outlined

previously.

2. Loosen the wing screw retaining the depth set rod.

3. With the router on a flat surface loosen the lock

lever and lower the router body until the bit just

touches the surface. Tighten the lock lever (Fig. 6).

3. Lower the tool until the tip of the router bit reaches

the desired depth. Engage the lock lever (fig. 6)

and loosen the adjustment screw on the depth

adjustment pole and let it fall freely until it makes

contact with stopper block. Then tighten the depth

adjustment screw (fig. 3).

Speed

Control

Dial

Fig. 3

Fig. 5

Fig. 4

Material

Hardwood

(Ash, Oak,

Jarrah, etc)

Softwood

(Pine, etc)

Chipboard

and MDF

Router Bit

Diameter

4-10mm

10-20mm

20-40mm

4-10mm

10-20mm

20-40mm

4-10mm

10-20mm

20-40mm

Approx.

Speed Setting

F-G(Max)

D-E

A-C

E-G (Max)

D-G (Max)

B-D

D-G (Max)

C-E

B-D

4. Lift up the depth set rod and rotate the triple depth

stop block to a suitable detent position.

5. Allow the depth set rod to rest on the threaded

bolt in the triple depth stop block and note the

scale reading where it enters the upper housing.

6. Add the required depth of cut to the scale reading

(in mm), move the depth set rod up to this reading

and tighten the depth set rod retaining screw. The

router is now set for the required depth.

NOTE: Always do a trial run of a new set depth on

a scap piece of material to ensure the depth of cut

is exactly as required.

7. If making a deep cut it is advisable to make more

than one pass to achieve the desired depth. The

depth of cut achievable with each pass depends

greatly on the size of the bit and the material

being worked, but no cut irrespective of bit size

Lock Lever

Fig. 6

should exceed 15mm. Excessive depth of cut will

unduly labour the motor, place excessive strain on

the bit, make the router more difficult to control

and significantly reduce the quality of the cut

being made.

8 The triple depth stop block can be used to assist

in making multiple passes, particularly when

working on more than one piece of material. If the

final depth of cut is set using the shortest of the

three threaded studs the two longer studs can be

set to two appropriately shallower depths. Using

the block in this way removes the necessity for

resetting the depth set rod for each pass.

Routing

1. Be sure the workpiece is clamped or otherwise

firmly secured.

2. Switch on the router and allow the motor to come

up to the full selected speed.

3. Plunge the bit down into the workpiece to the set

depth and lock it in place with the lock lever.

4. Holding the tool firmly with both hands progress

smoothly through the cut until complete.

5. Release the lock lever and allow the bit to come

free of the workpiece before removing the router.

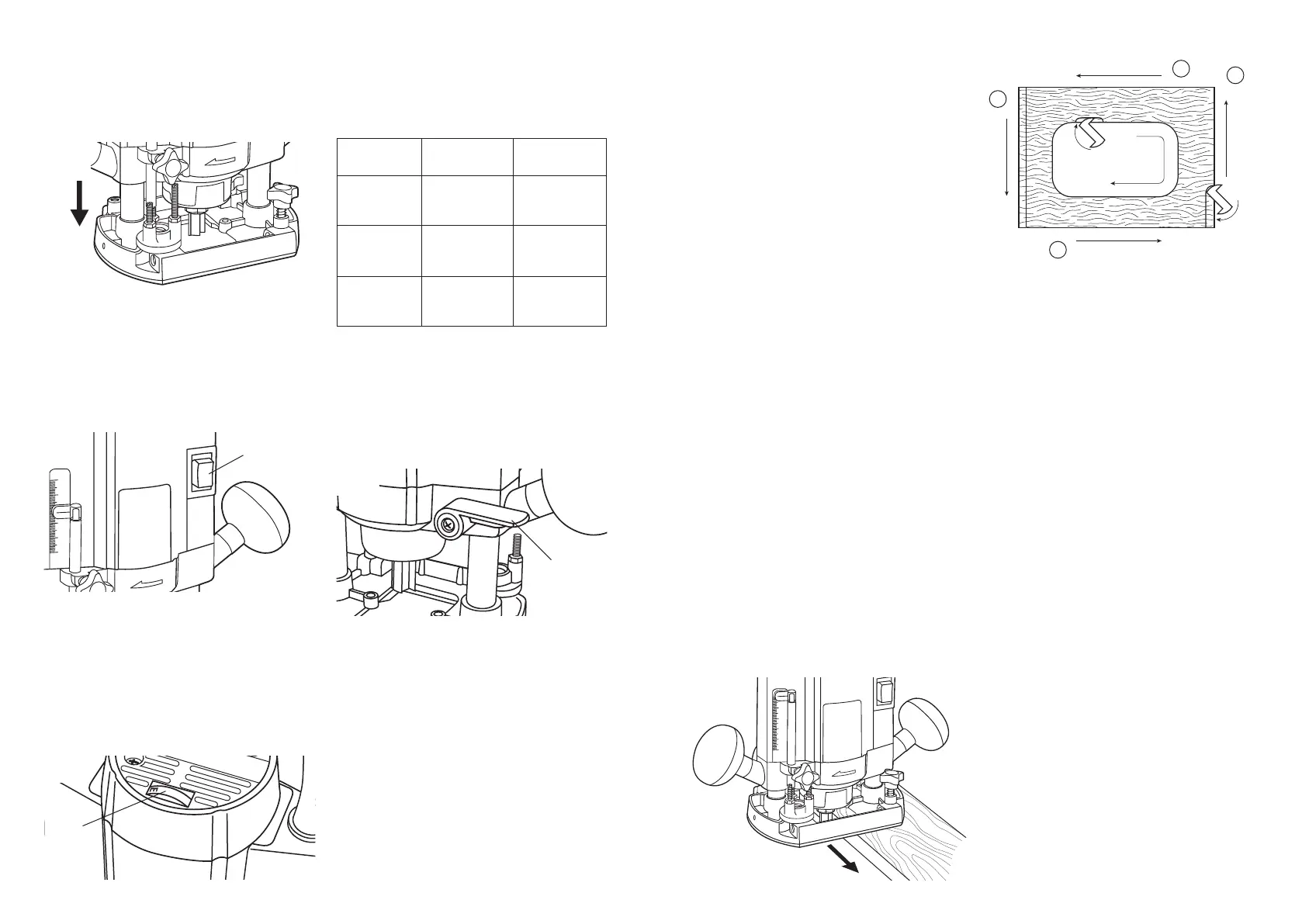

Direction of feed

The router motor, and therefore the bit, revolves in a

clockwise direction. This gives the tool a tendency to

twist counter clockwise in your hands, particularly

when starting the tool. The router bits are all

designed to use this clockwise rotation to assist in

the cutting and clearing of the material. Therefore

when using the router it should always be moved

from left to right as you are facing the workpiece

(Fig. 7). When cutting edges, move the router anti-

clockwise for outside edges and clockwise when

cutting inside edges. The diagram (Fig. 8) shows the

proper feed directions as viewed from the machine

side.

NOTE: Also the preferred sequence of outer edge

cuts when routing a board.

Loading...

Loading...