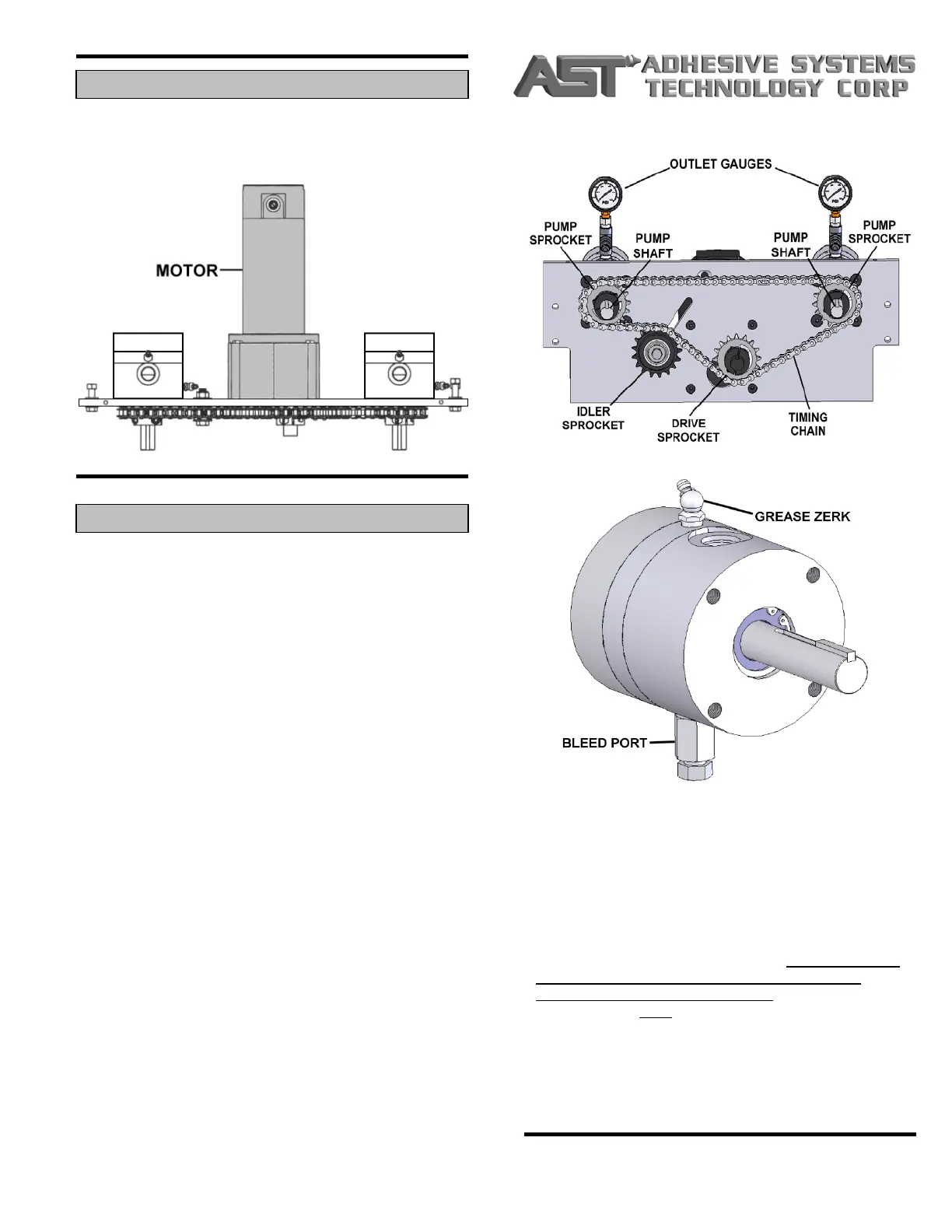

The GMP is driven by a TEFC 90 V D.C., variable speed

electric motor. The motor is fuse-protected; which is

located inside the controller. The internal gear reducer is

pre-lubed and sealed.

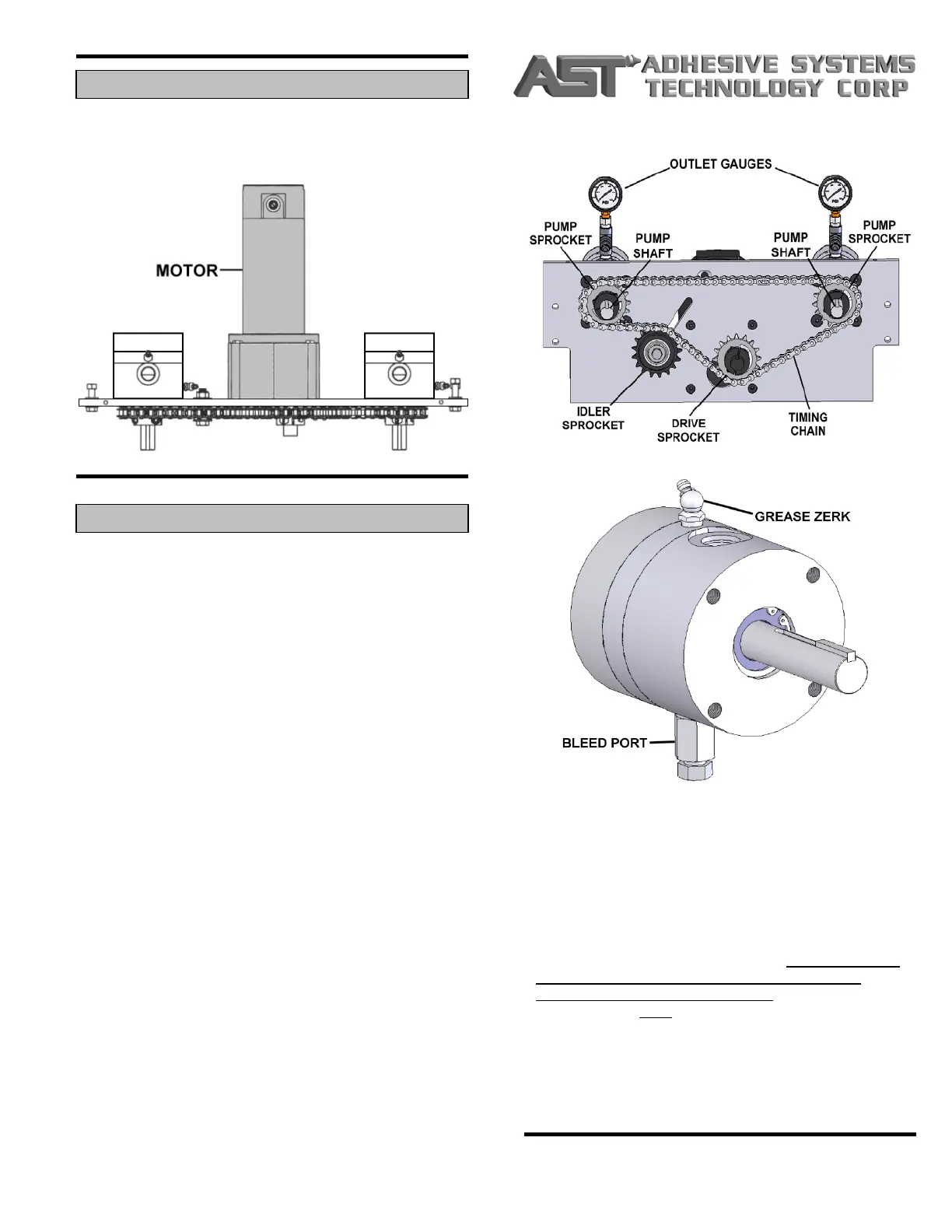

Two zerks for lubrication of the pump are provided. The

zerk closest to the pump shaft is provided for filling the

seal chamber. The zerk closest to the pump’s side

outlet is provided for lubrication of the metering gear

itself. Both should be filled daily with a lubricant

compatible with the material being dispensed. NOTE:

The second zerk cannot be filled without opening the

bleed port at the bottom of the pump. While the zerk on

the top of the pump is filled, the bleed valve at the

bottom of the pump must be opened. Lubrication is

complete when fresh lubricant is pushed out from the

bleed valve.

**Use caution when disassembling the Gerotor pump,

making sure not to gouge or mar any of the internal

surfaces of the pump.**

#60065-02: Page #3

Each AST gear metering pump consists of a hardened

drive shaft, lube chamber with dual shaft seals, metering

gear, material inlet block with air bleed port and a material

outlet assembly with gauge

In operation the pump shaft is connected to an inner drive

gear which, when turned, drives an outer internal driven

gear. The inner gear has one less tooth than the outer

gear allowing the pump to transfer material from the inlet

to the outlet of the pump, which are on opposite sides of

the gears. Precise tolerances prevent material by-pass as

the gears maintain a positive seal as the contours of each

gear are followed. Excessive wear or physical damage to

the surfaces of the working section of the pump will

reduce the ratio accuracy of the system.

Ratios are simply a function of the number of teeth on

either drive sprocket. Example: a 32 and a 16-tooth

sprocket will dispense at a 2:1 ratio by volume. In some

cases, dual stage pumps can be used on one side to

obtain a wider ratio.

Gauges on the outlets of the pumps allow the operator to

monitor pumping pressures. Pressure readings on the

gauges will almost always be different from “A” to “B”; this

is due to the difference in viscosities of the “A” and “B”

materials. The operator should pay attention to the

behavior over time of the gauges. Large variations often

indicate problems with obstructions, empty tanks/inlets, or

other problems.

3. GEROTOR PUMPS & MATERIAL OUTLETS

2. ELECTRIC DRIVE MOTOR & GEAR REDUCER

Loading...

Loading...