GENERAL DESCRIPTION OF

SYSTEM

The GMP-025 Meter-Mix-Dispense system has two

gerotor type gear metering pumps (GMP) that are

powered with an electric motor. The system consists of

seven major sections. Each of the components is

described below.

1. Inlet Assembly

2. Electrical Drive Motor & Gear Reducer

3. Gear Metering Pumps and Material Outlets

4. Delivery Hoses

5. Dispense Valve

6. Mixer

7. Controls

This system is designed for use only with the material

specified on the T.E.D. sheet for this system. Use of

other materials is not approved without explicit factory

consent and may cause poor results, damage the

system, or other problems, which is considered misuse

under AST warranty.

Each of the major sections is described below.

If supplied, the air dryer assembly (See BOM & Drawing

#55472A) consists of a desiccant canister connected by

polyurethane tubing to the bent in each tank lid. A small

window on the side of the canister allows the user to view

the contents. When the light blue to any other color, the

canister should be replaced.

NOTE: New canisters need holes punctured in each end

of the canister for the system to work properly. Failure to

do so will result in problems with the dispense ratio.

Each tank contains a screen assembly to prevent any

debris or unwanted particles from entering the pump. This

screen should be removed and cleaned periodically to

prevent blockage inside the tank.

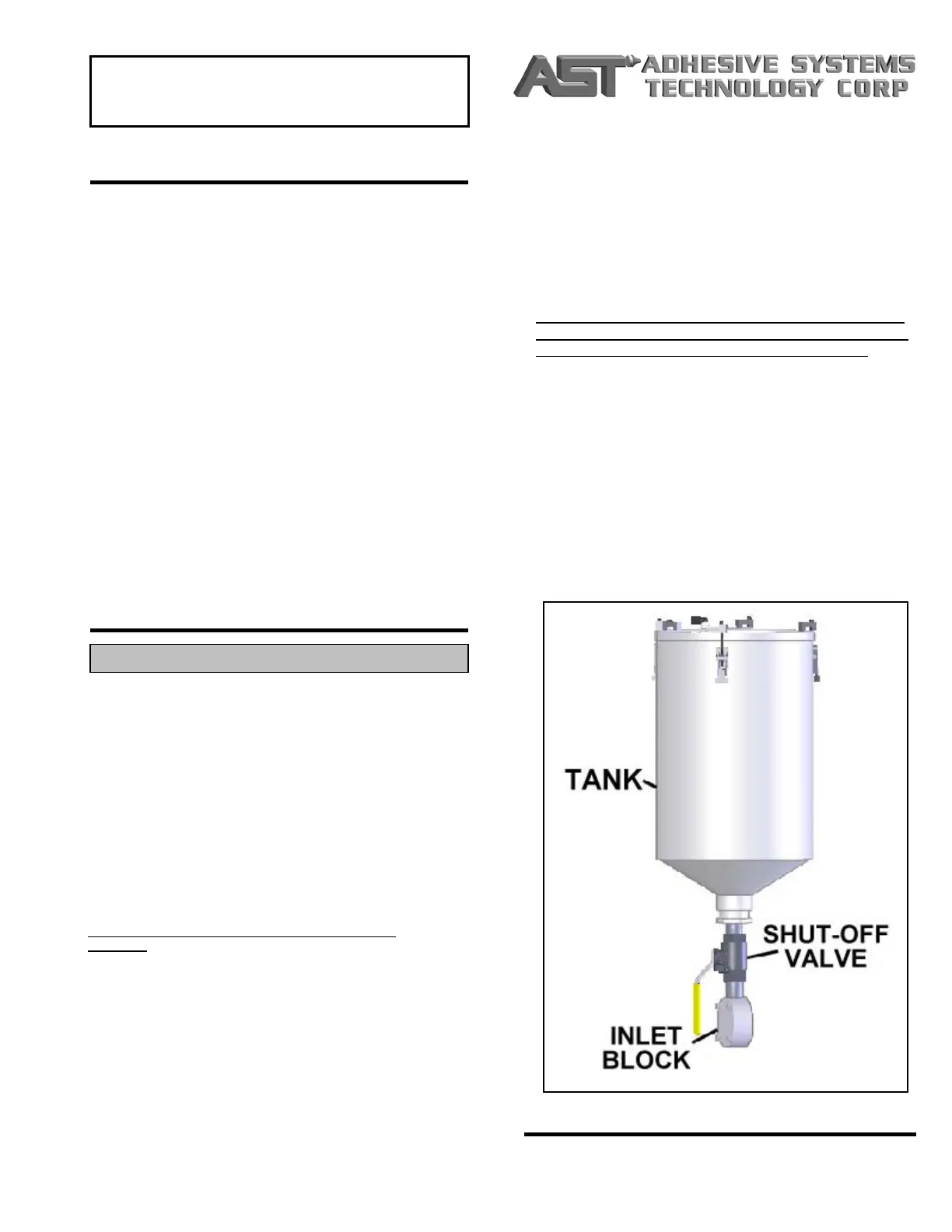

The inlet block connects the tank/inlet assembly to the

gear pump. The block is connected by (4) 5-16”-18 x 2-

1/4” bolts. Removing these 4 bolts will allow the entire

inlet assembly to be removed from the machine.

#60065-02: Page #2

Each inlet assembly consists of a tank, lid, manual shut-

off valve, and a pump inlet block. Typically, 5-gallon

stainless steel tanks with a cone bottom are supplied

with the unit (other options are available). The tanks are

piped to the gear pump inlets. Each tank has three lid

clamps, which may require occasional adjustment to

maintain the lid seal.

Manual shut-off valves are installed between the

material tanks and the gear pumps. These valves can

be shut before servicing the pump to allow most of the

material in the tank to remain inside. The valves should

also be shut during transportation of the unit.

NOTE: Each manual shut-off valve must be open during

dispensing.

Each lid has a silicone gasket that can be scraped out

when it becomes damaged over time. The shape of the

lid allows the gasket to be re-made with any RTV

silicone. Each lid also has a vent to allow air inside the

tank as the material is pumped out. For moisture-

sensitive materials, this vent is connected to an air dryer

assembly

1. INLET ASSEMBLY

Loading...

Loading...