IB-2003

eries 40 Trans

ite -

tationary

onveyor

34

Set-up

Receiving Hopper (optional)

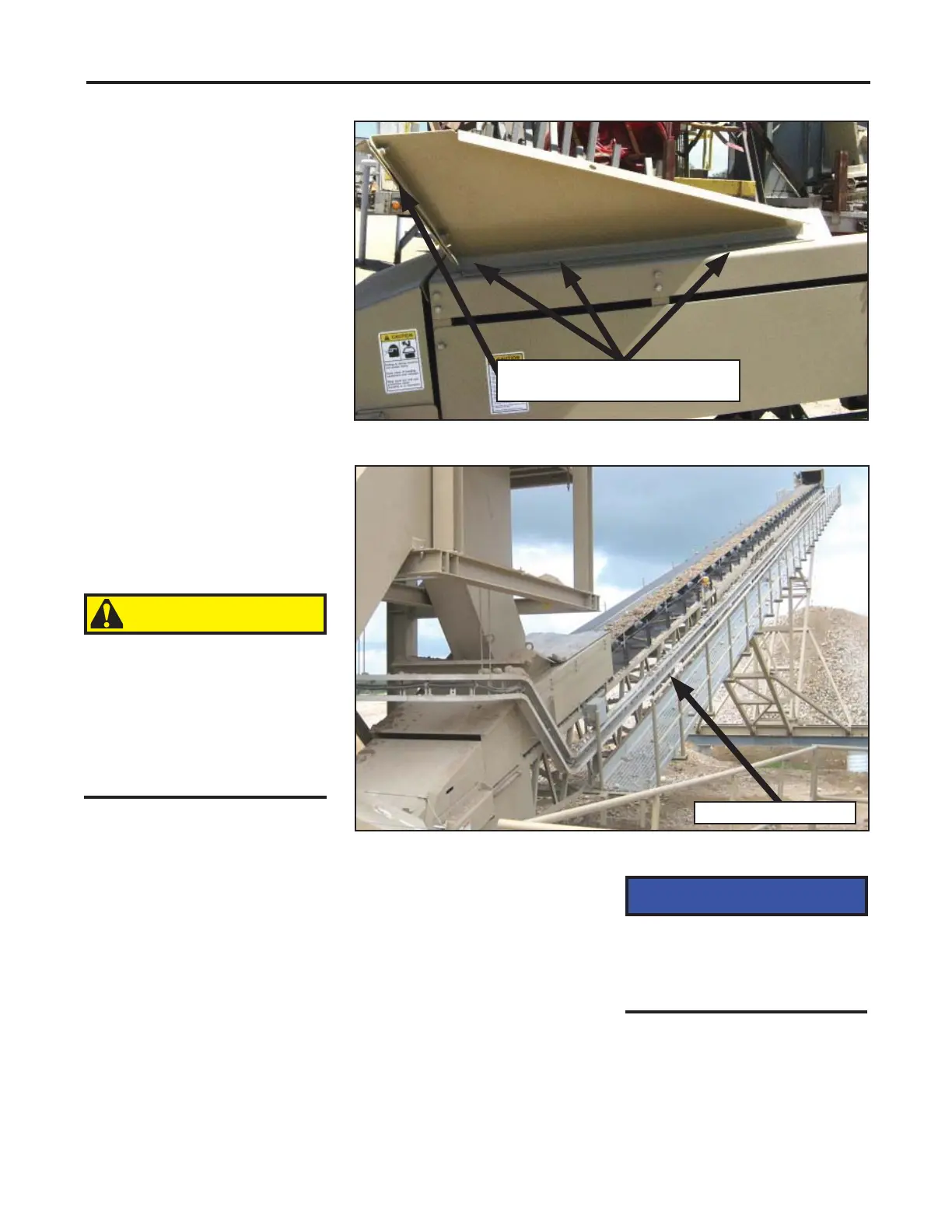

Assemble the optional receiving

hopper to the conveyor as

shown in the picture to the

right. Bolt the receiving hopper

to the tail end.

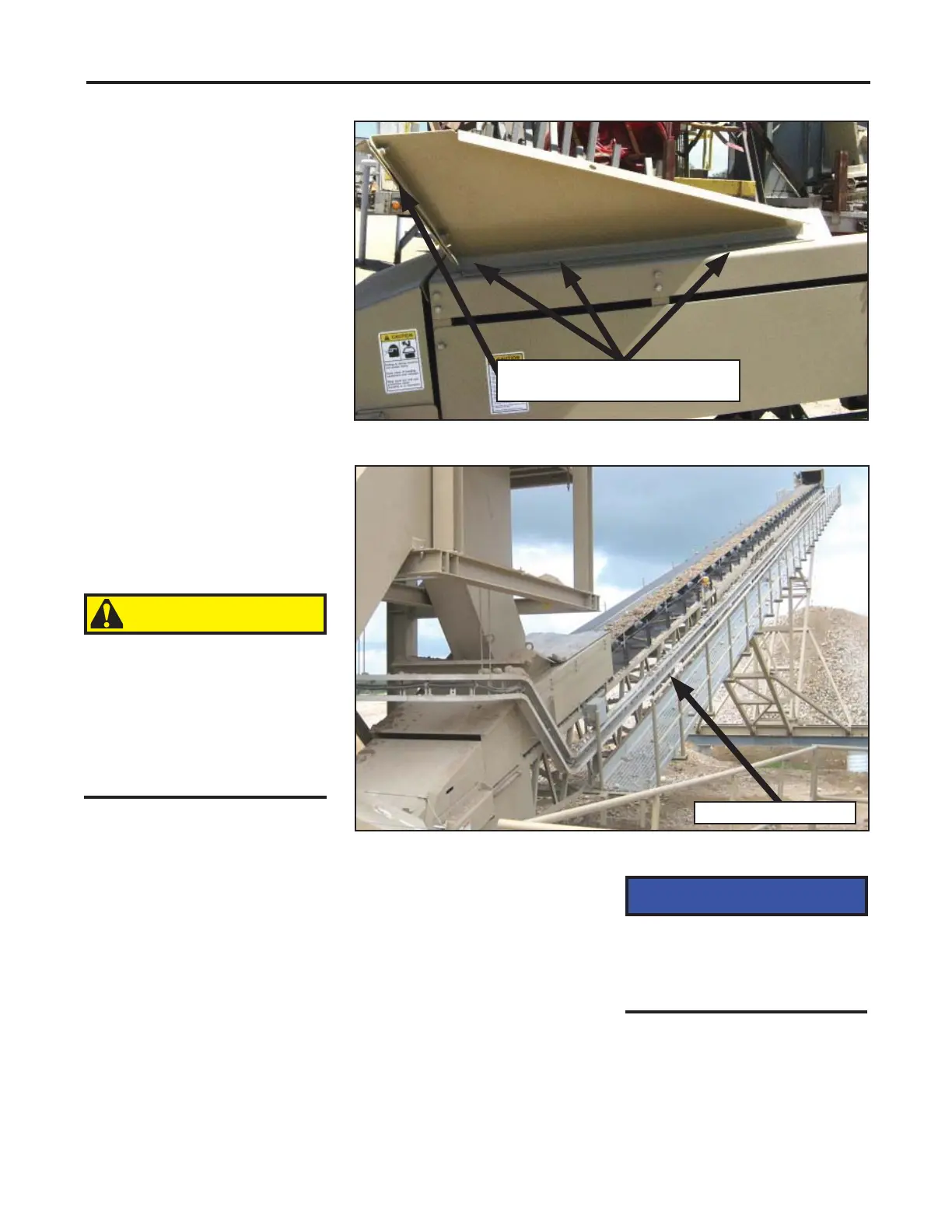

Assembly of the electrical

wiring can be done with a

cable tray.

1. Secure wire along the

conveyor frame and wire

in to the conveyor drive

motor.

2. Connect power to conveyor

drive.

3. Check the motor for proper

rotation before installing

Operating the conveyor

drive backward can cause

damage to the reducer,

backstop and motor.

Electrical

When the conveyor has been

assembled, the electrical

wiring can be completed.

Installation and maintenance

of electrical devices must

comply with all applicable

codes and regulations and

must be done by a qualifi ed

electrical contractor.

NOTICE

CAUTION

Assembling Receiving Hopper to Conveyor

Hopper is bolted to conveyor in

four places on each side.

Drives

Reducers are shipped from the

factory fi lled with oil; however,

check the oil level in the

reducers and fi ll if necessary.

drive belts. Rotation

direction is typically marked

on the motor housing or

guard.

On drives with v-belts installed,

it will be necessary to relieve

belt tension enough to allow

belts to slip when checking

drive rotation.

Relieve tension on reducer

v-belt by loosening motor

mount nuts. Turn nuts as far

as possible. Do not loosen

top nuts.

Cable Tray Installed on Conveyor

Electrical cable tray

Loading...

Loading...