IB-2003

eries 40 Trans

ite -

tationary

onveyor

36

Cover pin

Conveyor Belt

Conveyor Belt Installation

The proper installation of

the conveyor belt is critical

to conveyor performance

and belt life. An improperly

installed belt can result in

damage to the belt, material

spillage and excess power

demands.

The conveyor belt has been

shipped cut to the correct

length. Additional length has

been provided to properly

square the belt.

Use the following procedure to

install the conveyor belt.

1. A frame should be

constructed to support the

conveyor belt roll.

Belt Support Frame

Do not bend or kink the belt

while installing.

Belt Installation

Belt Tensioning

Proper belt tension is diffi cult to

defi ne. The belt must be tight

enough to prevent slipping at

the head end, but not so tight

that excess power is required

and damage occurs to the

conveyor.

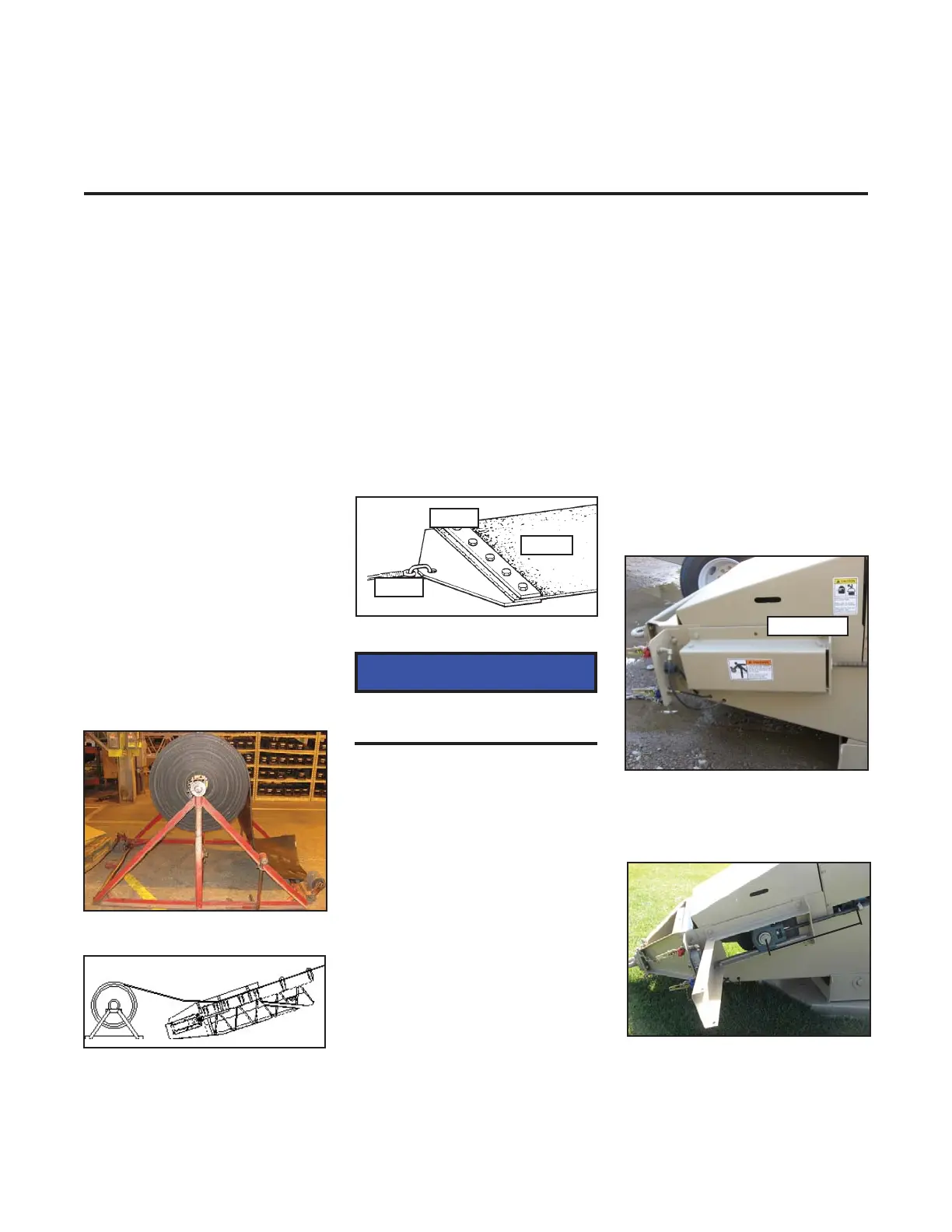

1. To adjust belt tension,

remove take-up rod cover

by removing the pin on

top of the cover.

Belt Support Frame

NOTICE

2. Measure from the take-up

to the bearing on each

side.

2. Insert a bar through the

center of the belt roll and

onto belt support frame.

3. Guide the belt over the top

of the troughing and return

idlers. A cable and clamp

can be attached to the belt

to help pull the belt around

the conveyor. Use the same

hole spacing required for

the belt fasteners.

4. After the belt has been

pulled entirely around the

conveyor, pull as much

slack as possible from the

conveyor belt. A clamp

arrangement can be used to

pull belt ends together.

5. Place a piece of plywood or

wood block under the

conveyor belt where the two

ends overlap to provide a

cutting surface.

Belt

Clamp

Cable

Loading...

Loading...