IB-2003

eries 40 Trans

ite -

tationary

onveyor

37

Conveyor Belt

Belt Splicing

In some cases the belt

has been pre-sliced. If the

conveyor belt is not spliced

squarely, it will run off at the

splice. Use the following

procedure to check that splice

is square and adjust.

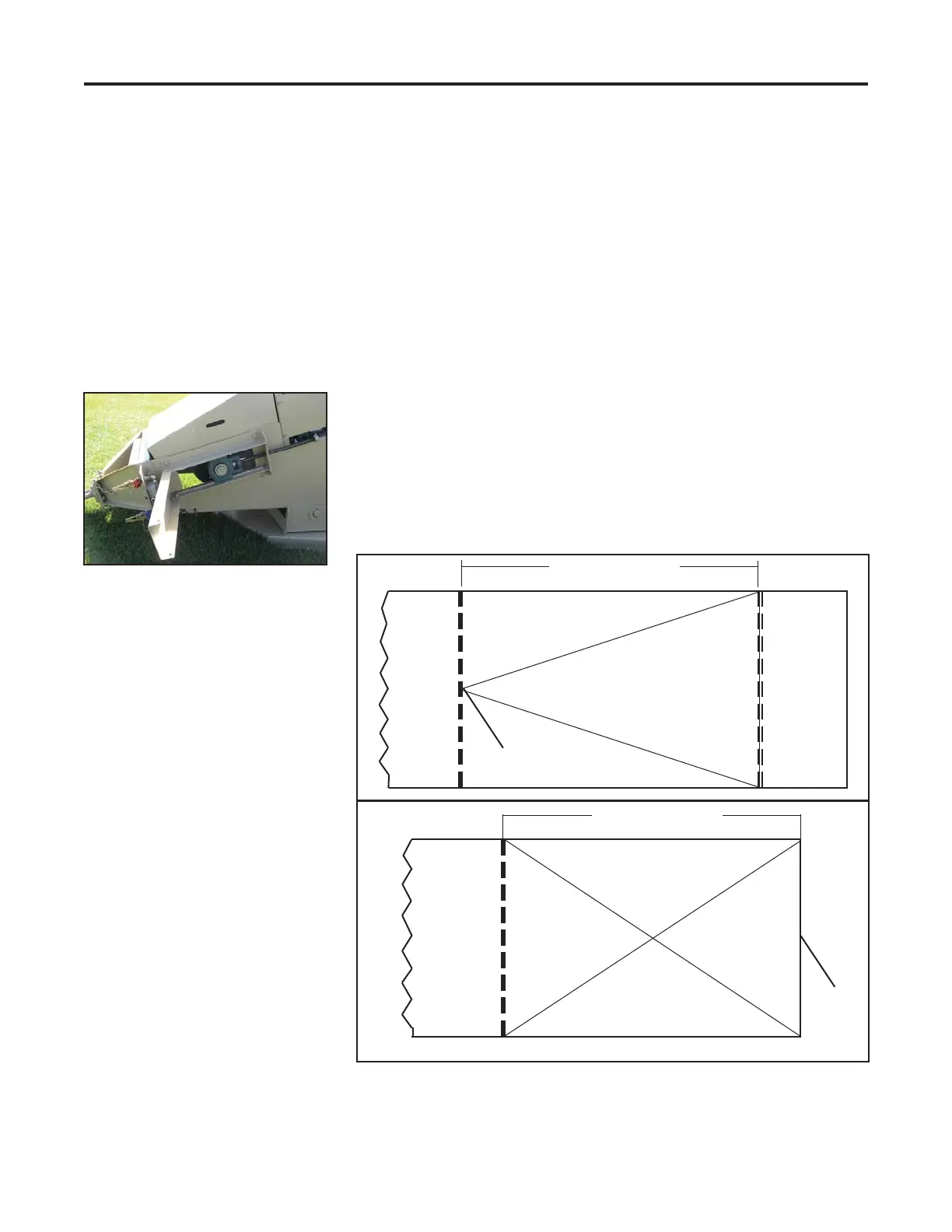

3. From the center point,

measure up to the splice on

the opposite side. This

measurement should be the

same. If the measurement

is not the same, it will be

necessary to recut and

resplice.

4. The squareness of the

splice can be further

checked by measuring the

distance from corner to

corner.

5. Install the mechanical

fasteners (if equipped).

3. Turn the take-up screw rod

until the proper tension is

achieved. Tighten each

side equally to prevent belt

damage. Measure again

from the take-up to the

bearing on each side to

make sure that take-up

screw rod has been

tensioned equally on both

sides.

4. Check tail pulley shaft for

squareness to the frame,

adjust as required.

4 ft. Approximate

Belt splice

Center point

B

D

4 ft. Approximate

A

C

Belt end

The measurement from A to B should be equal to the measurement from

C to D.

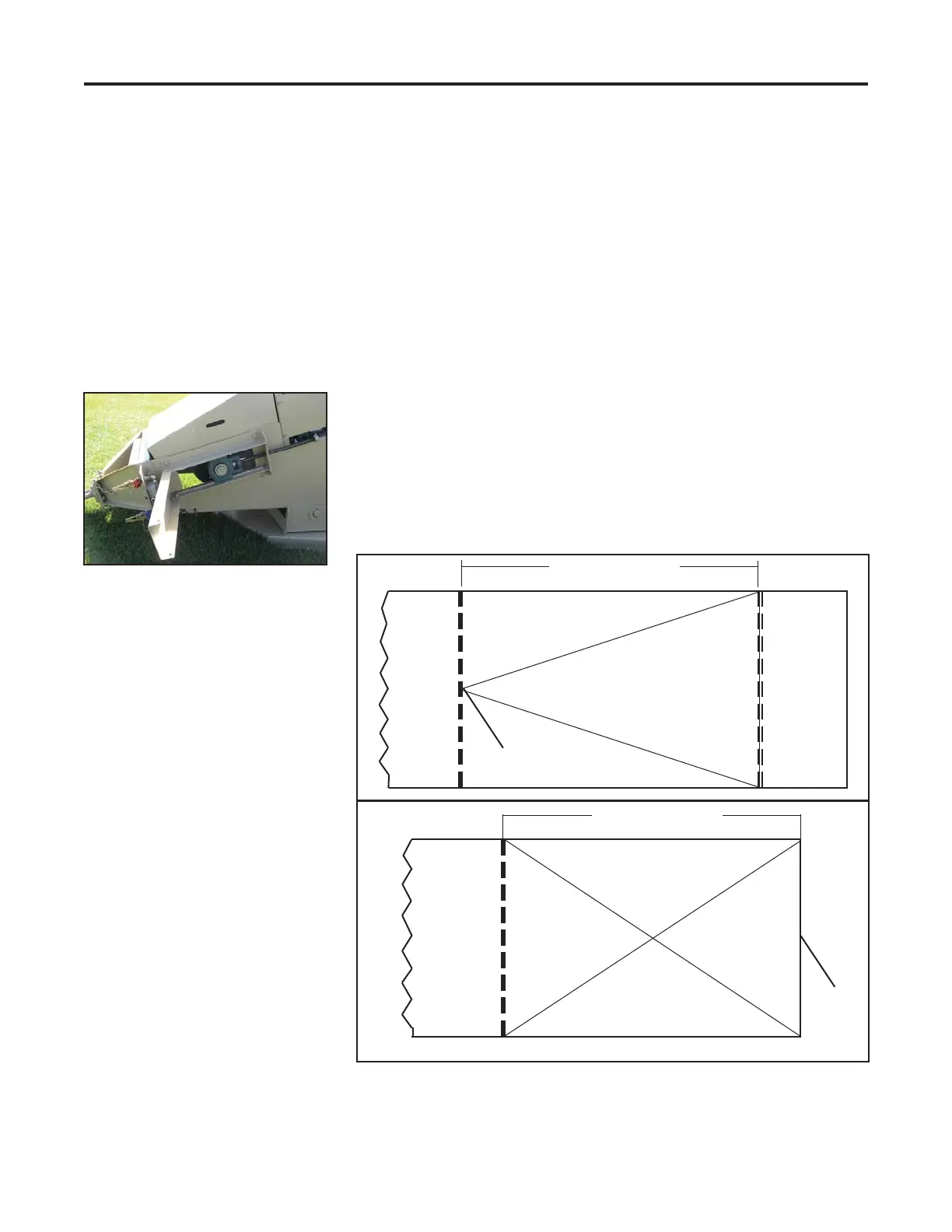

A template, cordless drill and

clamps will be needed to

complete the belt splice.

1. From one end of the splice,

measure approximately

four feet down the side of the

belt and mark that point.

2. Using a carpenter’s

square, fi nd the center of

the belt from the four foot

mark by measuring half the

distance of the belt.

Loading...

Loading...