Astec Mobile Screens Maintenance 33 KDS 710

710

KDS

by adjusting the return idlers. After adjusting

return idlers, if belt is still straying, adjust several

idlers behind the point at which the belt strays.

Begin the troubleshooting process by perform-

ing this adjustment on the opposite side of the

belt that runs off the roller.

Do not attempt to make extreme adjustments to

one idler. Instead, make several slight adjust-

ments to several idlers. Always allow several

rotations to occur before determining belt align-

ment.

After idlers have been adjusted, place a load

onto conveyor and check for alignment. If nec-

essary, repeat idler adjustments until content

with alignment.

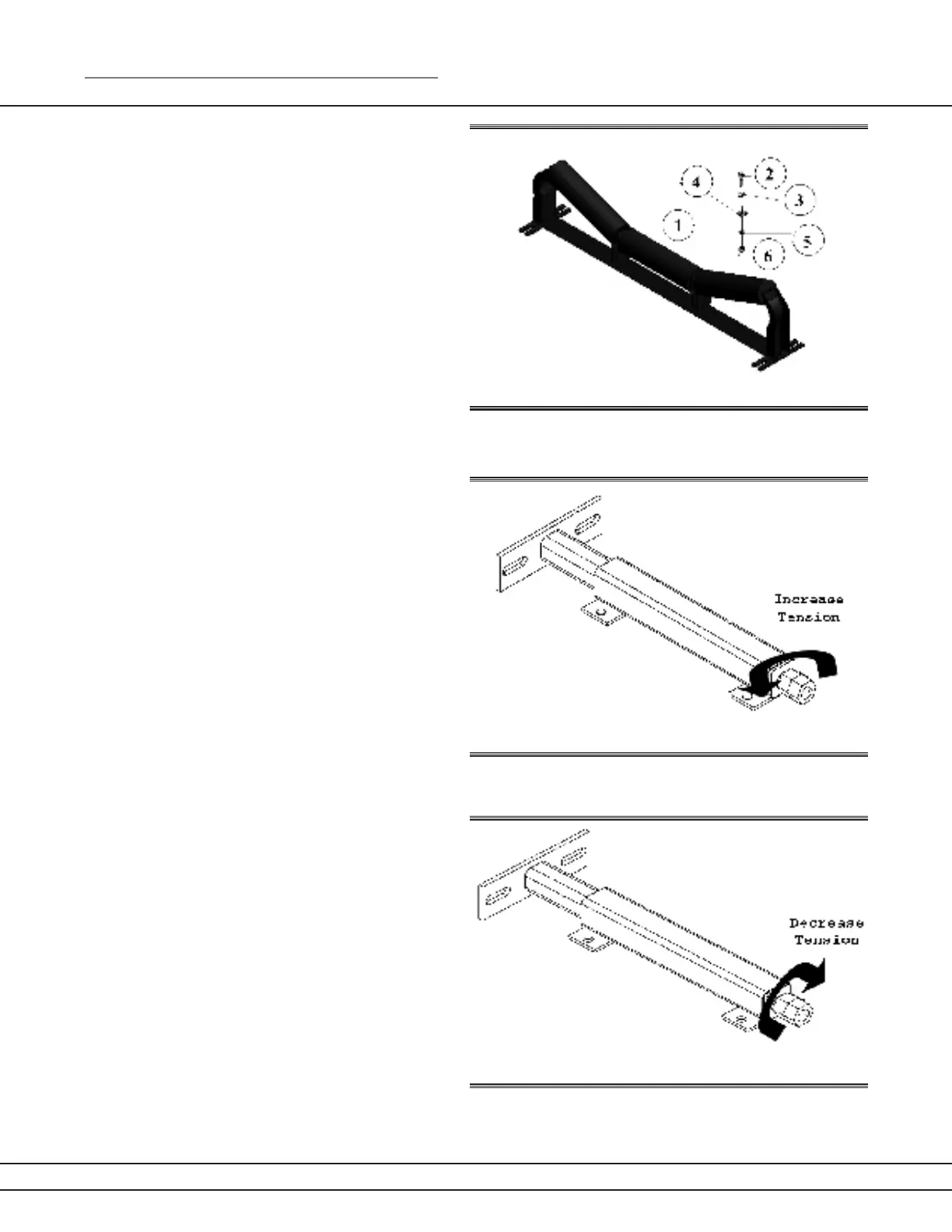

2. If adjusting the idlers does not work, an

adjustment to the take-up screws may be

necessary. The screws are located on either side

of the head/tail pulley, and can be adjusted with

a 1 5/8” socket.

This is not the most common cause of a mis-

aligned belt, but the process can be used as a

last resort to troubleshoot the situation.

Ensure the head pulley is properly aligned

with the tail pulley by adjusting the take-up

screws. By increasing the tension on either

side of the head/tail pulley, the belt will shift

in that direction.

By decreasing the tension to either side of

the head/tail pulley, the belt will shift in the

opposite direction. Keep in mind that the

head/tail pulley must stay parallel with the

conveyor frame. If the head/tail pulley is

not parallel with the conveyor, the belt will

stray. By adjusting the head pulley you are

attempting to create a parallel line with the

conveyor frame.

After adjusting the take-up screws, run the

belt and check for proper alignment. Allow

several full rotations of the conveyor belt before determining satisfaction of alignment.

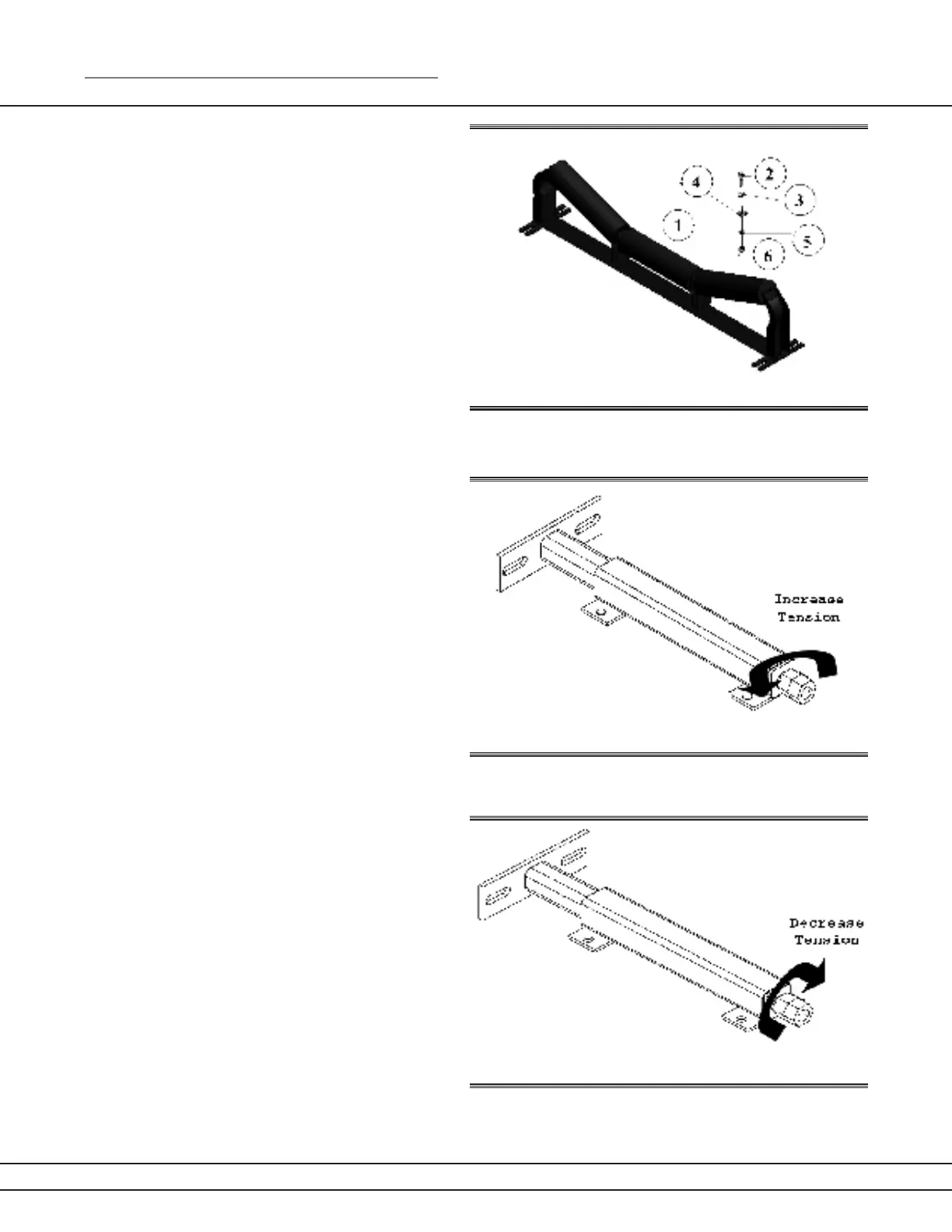

Figure 33a

Figure 33b

Figure 33c

Loading...

Loading...