710

KDS

Astec Mobile Screens Maintenance 34 KDS 710

Belt Tension

If belt is sagging excessively when a load is

applied, it may be necessary to increase belt

tension. Use the take-ups to increase and de-

crease belt tension. When adjusting belt tension

be sure that the distance at which the take-ups

are extended is equal on both sides of head/tail

pulley. Improperly aligning the head/tail pulley

will cause the belt to stray. Be certain not to

create to much tension on the belt.

Guards

Make sure return idler guards are in proper

place and are not damaged. Guards should

be tilted at the proper angle and free from

obstructions. Guards should not be rubbing the

conveyor belt.

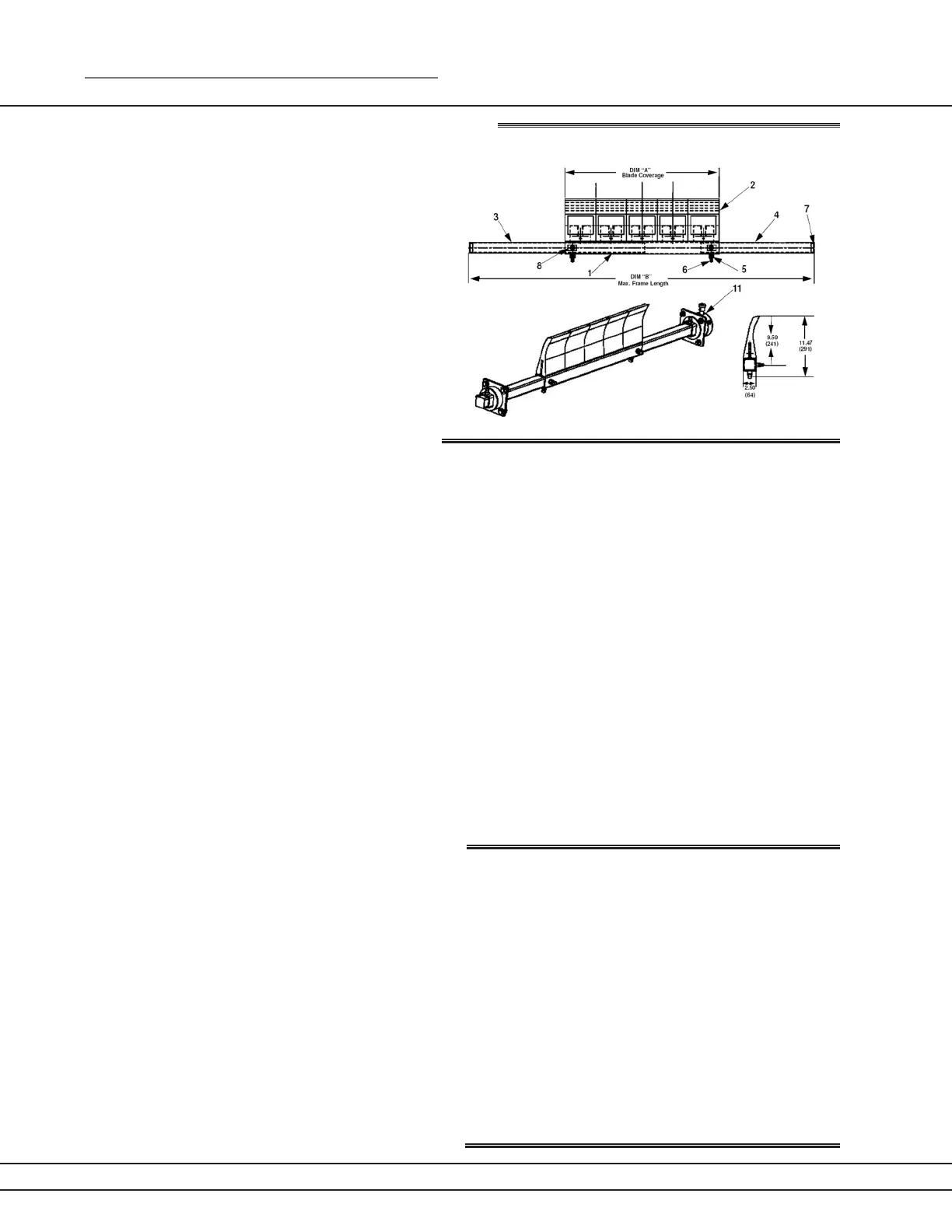

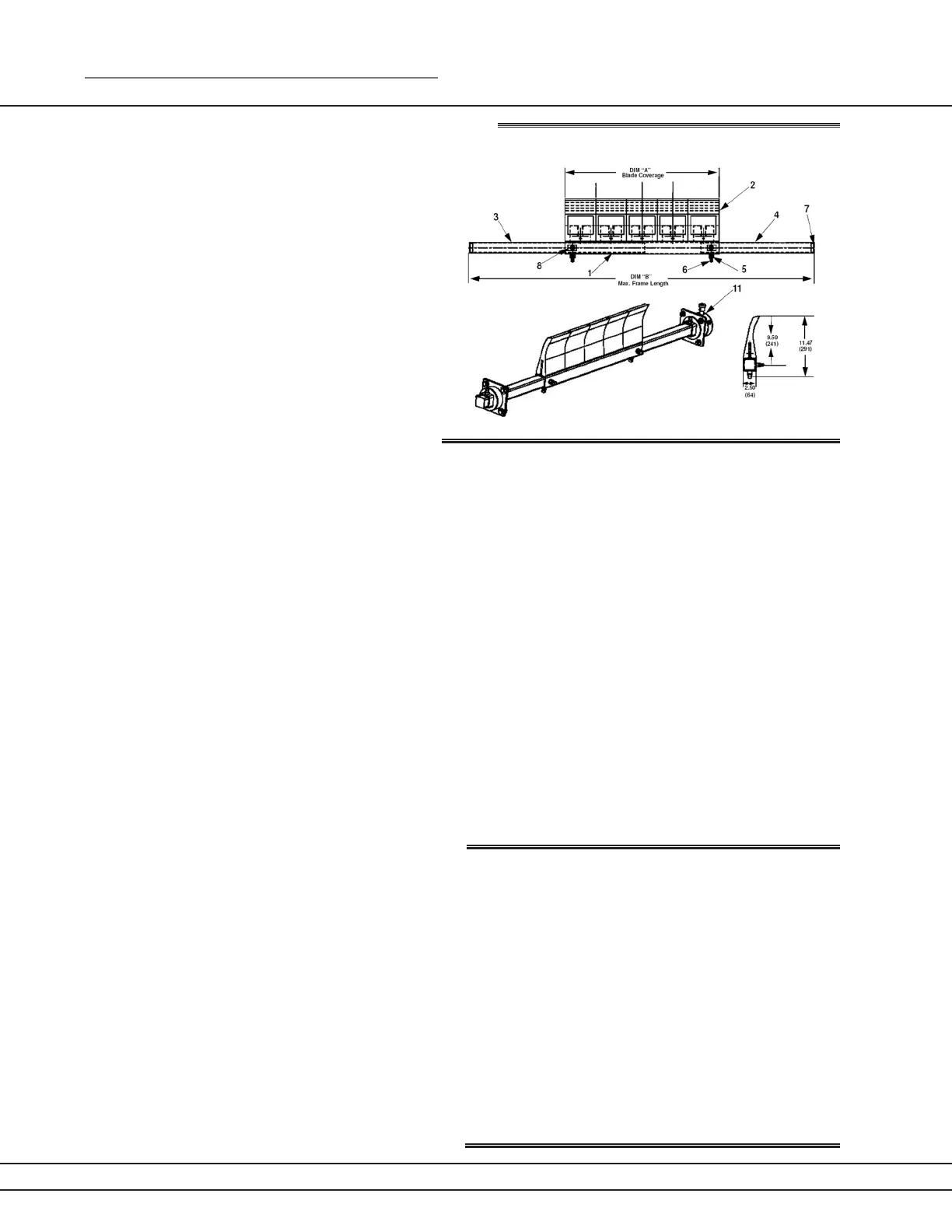

Belt Cleaners

Located at the head pulley end of the side and delivery conveyors are the belt cleaners.

Make sure all fasteners are tight. Tighten if necessary. Inspect the belt cleaner for excessive wear.

Allow 3” of wear on urethane. If blades are worn beyond the wear line, replace as follows.

1. Release tension on mainframe and remove belt cleaner assembly.

2. Use a hammer to remove worn blades from mainframe by pounding downward on bases of worn

blades. Pound new blades onto mainframe after old blades have been removed.

3. Change worn blades with appropriate replacements.

See tension setting decal placed next to belt cleaner for proper tension settings. See the Parts Section

of this manual for replacement part information.

Consult the full belt cleaner manual in the Appendix for more detailed information.

Bearings

Visually inspect bearings on head and tail pulleys. A small amount of grease around seal is normal.

Excessive grease or lack of grease around seals may be a sign of bearing temperature problems. For

a detailed description of the greasing schedule, refer to Appendix A.

The plant is equipped with ground level accessible grease zerks. Please consult the greasing schedule

in Appendix A for information regarding proper greasing intervals.

Figure 34a

Loading...

Loading...