Astec Mobile Screens Maintenance 35 KDS 710

710

KDS

NOTE: When greasing bearings DO NOT over grease! Over greasing will place too much stress

on the seals, causing them to no longer function correctly.

Abnormal bearing temperature may indicate poor lubrication. Normal operating temperatures may

range from cool to touch to too hot to touch, depending on bearing size, speed and surrounding

conditions. Unusually high temperature accompanied by excessive leakage of grease indicates too

much grease. High temperature with no grease showing at the seals, particularly if the bearing is noisy,

usually indicates too little grease.

The bearings have been lubricated at the factory

with No. 2 consistency lithium base grease. This

grease is suitable for normal operation conditions.

Re-lubricate bearings with lithium base grease

or a grease which is compatible with the original

lubricant and that is suitable for ball bearing

service. In unusual or doubtful cases, contact

your local Astec Mobile Screens Dealer.

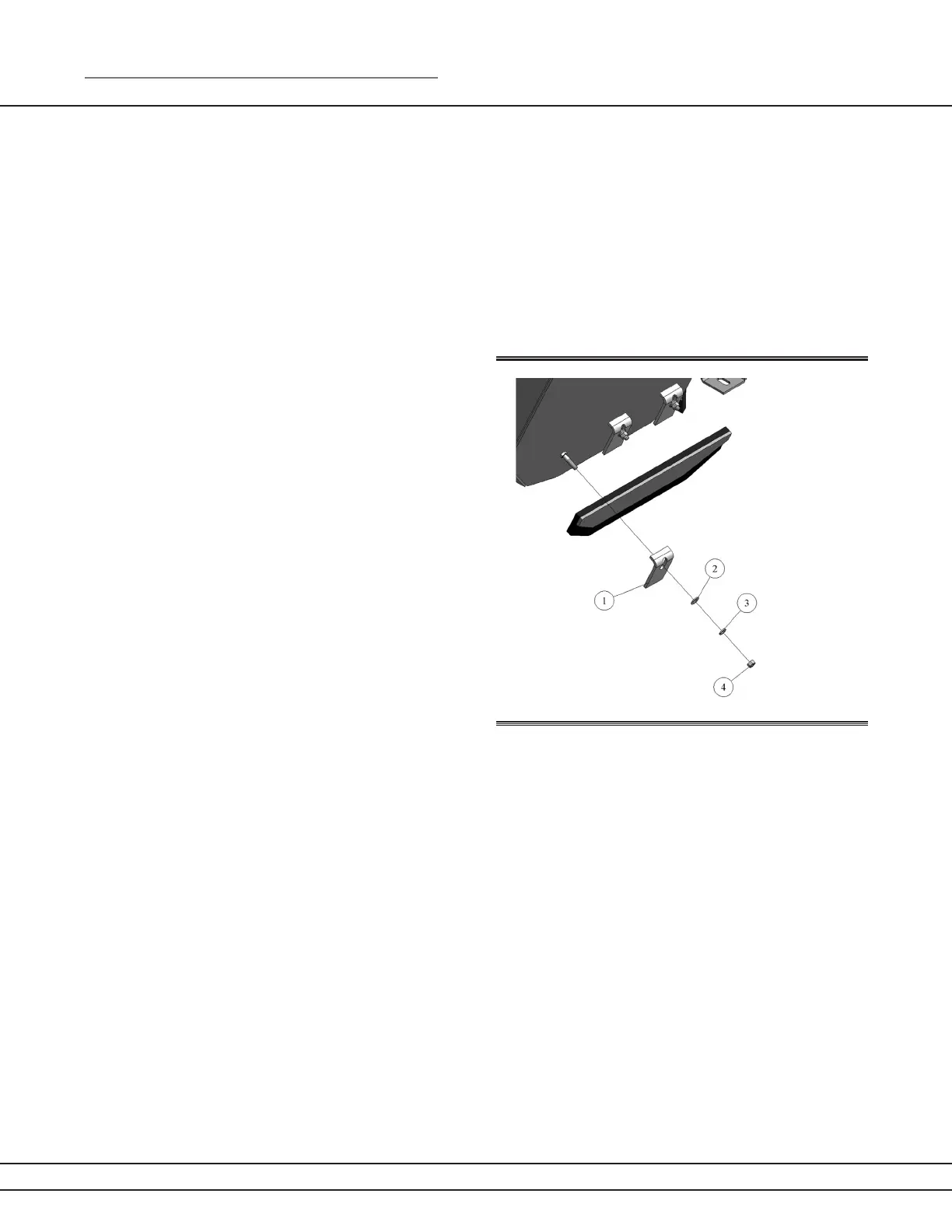

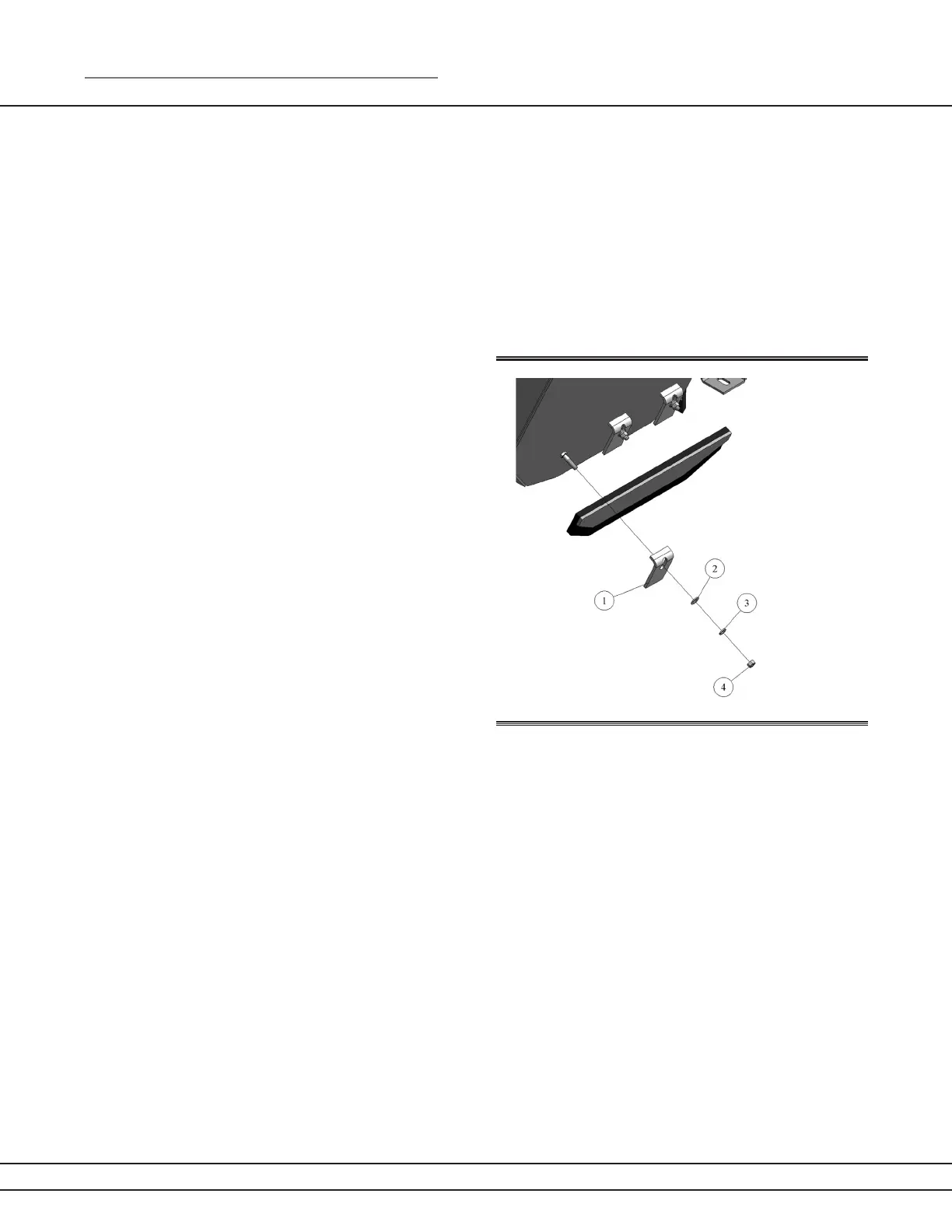

Flashing

Check Flashing inside of top deck, bottom deck,

feed bin, screen box hoppers, and delivery

conveyor. Flashing is used to prevent spillage

from occurring.

In order to properly prevent spillage, ashing

must be ush with conveyor belt, with a minimum

gap. Check to make certain ashing is not

excessively rubbing conveyor.

If ashing is not aligned correctly or needs to be re-aligned, loosen tension brackets (1) by loosening

nut (4) and adjust ashing to proper position.

After realignment, tighten tension bracket nuts. If ashing is worn to the point that it is not preventing

spillage, replace ashing with correct replacement part. See parts section for specic ashing sizes.

Figure 35a

Loading...

Loading...