erensan°

“The Heating Engineer”

- 15 –

280111

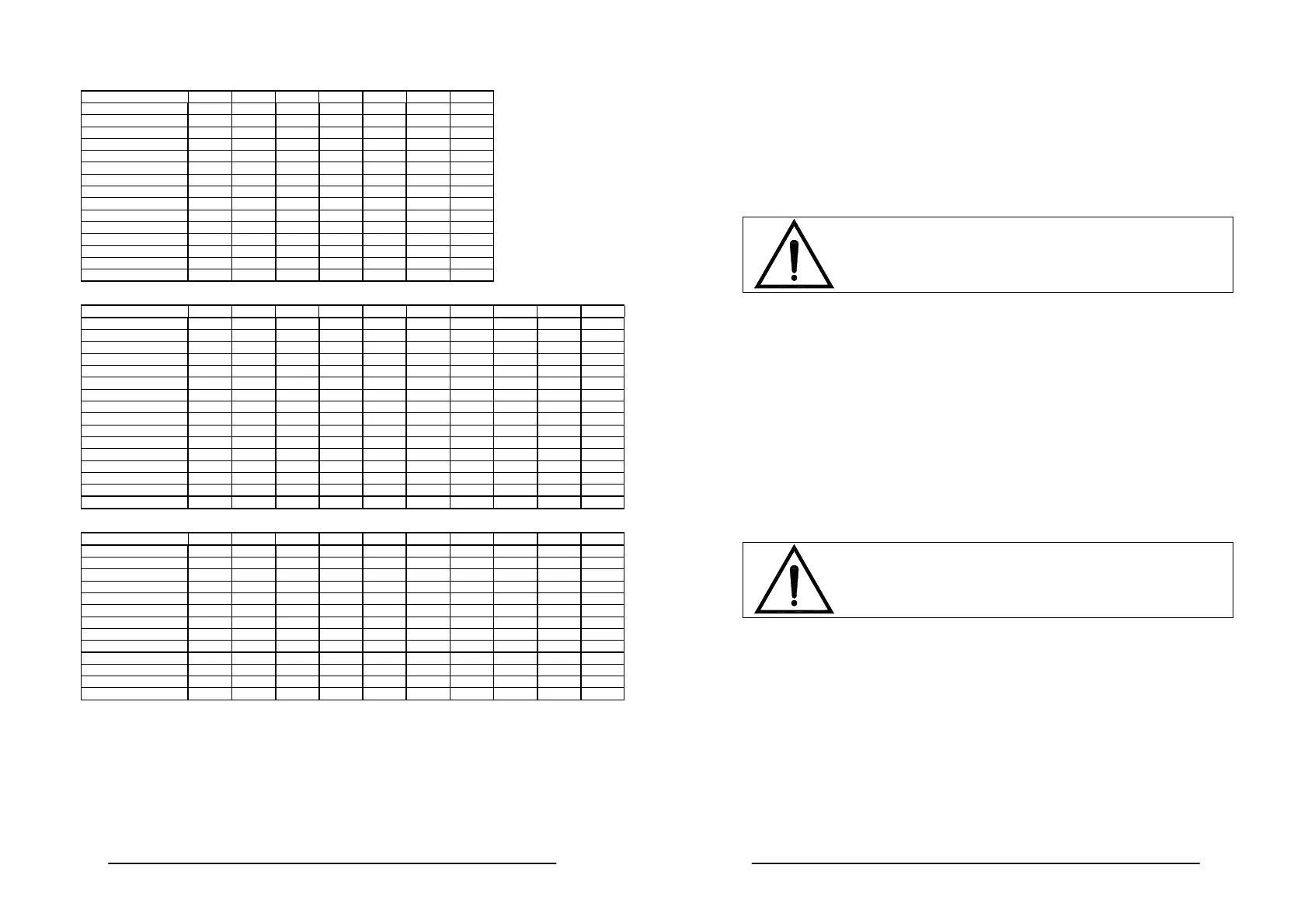

BOILER DIMENSIONS FOR DIFFERENT BOILER TYPES

ESB

TYPE ESB 100 125 150 200 250 300

Capacity kg/h 1000 1.250 1.500 2.000 2.500 3.000

Capacity kW 655 818 982 1.309 1.637 1.964

Water volume

m

3

1,75 2,12 2,60 3,13 4,05 4,33

a mm 2.730 2.885 3.240 3.390 3.830 3.830

b mm 1.584 1.644 1.704 1.842 1.946 2.035

c mm 1.500 1.500 1.500 1.500 1.570 1.670

d mm 2.836 3.110 3.446 3.596 4.034 4.034

e mm 1.870 2.125 2.270 2.370 2.810 2.810

g mm 1.683 2.043 2.103 2.242 2.346 2.432

h mm 1.840 1.897 1.992 2.102 2.245 2.352

h1 mm 1.120 1.162 1.248 1.290 1.380 1.400

h2 mm 956 986 1.040 1.090 1.160 1.236

Ø

k

mm 250 300 350 350 400 400

Pressure loss mbar 5,5 7 8 8 8,5 9,0

Empty weight ton 3,4 4,06 4,346 5,1 5,976 6,936

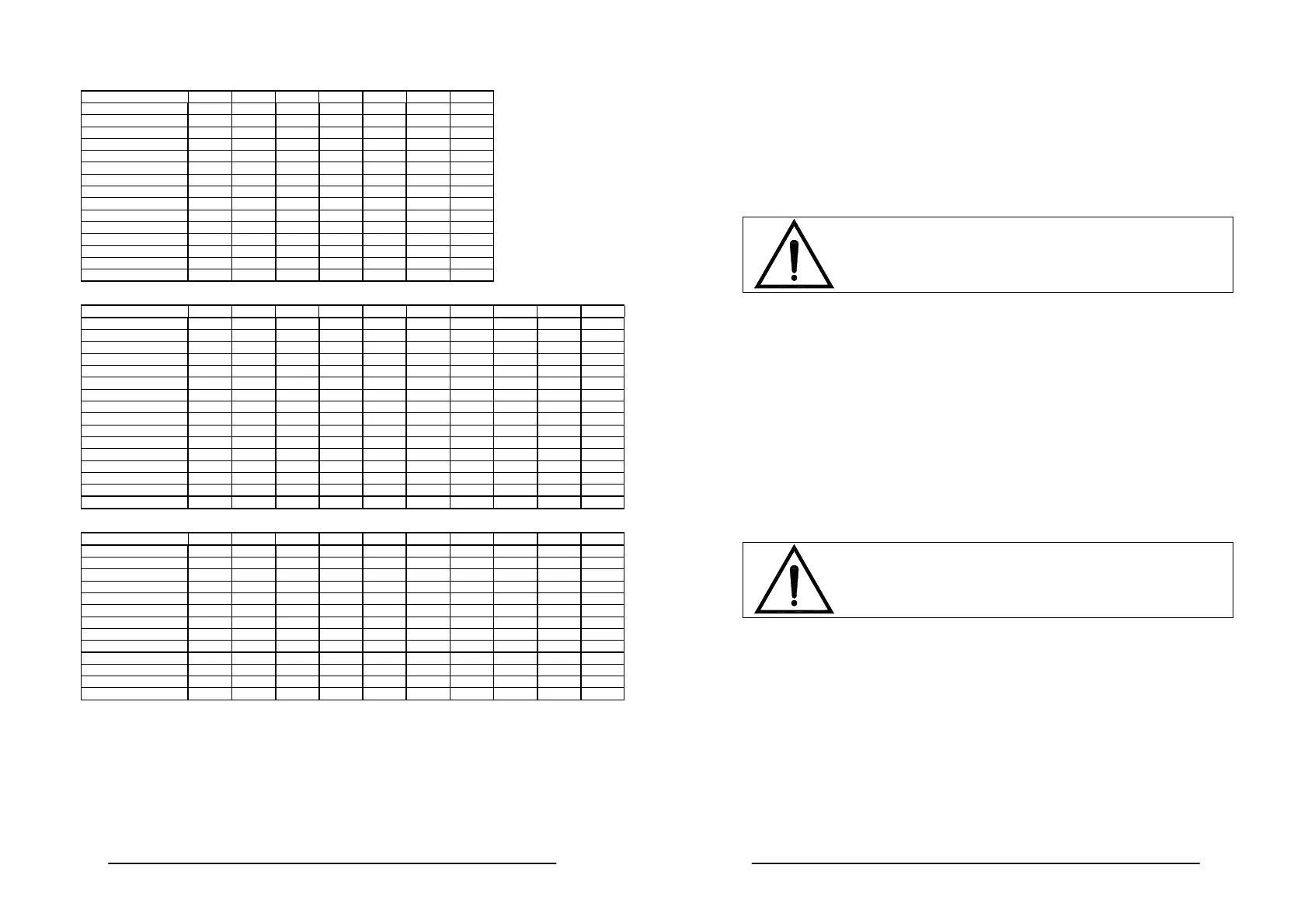

TYPE ESB 400 500 600 700 850 1000 1200 1400 1500

Capacity kg/h 4.000 5.000 6.000 7.000 8.500 10.000 12.000 14.000 14.000

Capacity kW 2.619 3.273 3.928 4.583 5.565 6.547 7.856 9.165 9.820

Water volume

m

3

9,36 11,80 12,90 14,50 16,50 18,00 23,80 27,20 29,50

a mm 4.635 5.000 5.072 5.411 5.479 5.833 6.483 6.633 6.874

b mm 2.418 2.590 2.720 2.820 2.992 3.062 3.269 3.439 3.462

c mm 1.970 1.970 2.050 2.050 2.360 2.400 2.400 2.500 2.700

d mm 5.215 5.600 5.710 6.015 6.215 6.570 7.220 7.370 7.610

e mm 500 500 550 550 650 650 650 650 650

f mm 3.445 3.770 3.840 4.226 4.280 4.690 5.055 5.370 5.650

g mm 2.742 2.909 3.040 3.139 3.047 3.477 3.684 3.852 3.875

h mm 2.715 2.890 3.022 3.122 3.371 3.440 3.642 3.794 3.816

h1 mm 2.100 2.154 2.260 2.384 2.551 2.551 2.755 2.870 2.900

h2 mm 965 985 1.040 1.053 1.161 1.171 1.222 1.246 1.313

Ø

k

mm 600 600 700 700 800 800 900 1.000 1.000

Pressure loss mbar 7,5 8,0 8,5 8,0 8,5 9,5 10 11 11

Empty weight ton 8,663 9,94 12,425 13,7 15,3 17,507 20,04 22,585 24,476

TYPE ESB 1600 1800 T-1800 2000 T-2000 2500 T-2500 3000 T-3000

Capacity kg/h 16.000 18.000 18.000 20.000 20.000 25.000 25.000 30.000 30.000

Capacity kW 10.474 11.784 11.784 13.093 13.093 16.366 16.366 19.640 19.640

Water volume

m

3

29,80 34,50 34,50 36,50 36,50 38,80 38,80 41,00 41,00

a mm 7.102 7.732 5.575 7.810 5.660 8.602 6.235 8.602 6.235

b mm 3.521 3.566 4.073 3.600 4.155 3.796 4.423 3.969 4.455

c mm 2.700 2.860 2.900 3.000 3.000 3.500 3.500 3.500 3.500

d mm 7.840 8.518 7.980 8.596 8.115 9.388 8.890 9.388 8.890

e mm 650 700 1.300 700 1.300 700 1.400 700 1.500

f mm 5.840 6.190 4.215 7.000 4.795 7.342 5.028 7.342 5.028

g mm 3.934 4.033 4.466 4.063 4.552 4.210 4.876 4.381 4.956

h mm 3.875 3.900 4.526 4.050 4.698 4.164 3.590 4.164 3.590

h1 mm 2.950 2.950 * 3.065 * 3.266 * 4.190 *

h2 mm 1.282 1.250 1.700 1.350 1.750 1.382 1.780 1.400 1.800

erensan°

“The Heating Engineer”

- 16 –

280111

BOILER OPERATING PERSONNEL

The personnel to be charged with boiler operation are

responsible for intervention in case of any emergency. For this

purpose, they must be fully informed about the functions,

operating characteristics, operating pressure and temperature

and flow quantities; they should know the functions and

operation of all control circuits and measurment devices and

electrical safety hardware well.

TRANSPORTATION AND TEMPORARY STORAGE

The boiler should be transported using the lifting and

transportation points and utilizing appropriate equipment.

For horizontal movement, horizontal displacement is possible

through controlled sliding on pipes when it is not possible to

utilize a winch.

The boiler should be protected against mechanical blows and

collisions during loading, transportation and unloading.

During temporary storage before transportation and

installation, the boiler must be protected against damages that

may result due to moisture and external mechanical agents.

INSTALLATION

Boiler installation site should comply with the related standards

and procedures. Boiler room door should open outside and

fresh air inlet at floor level and polluted air outlet at ceiling

level should exist. More than one boiler should not be

connected to the same chimney.

The boiler should be installed on a foundation elevated from the

floor at the installation site. The back feet have been

manufactured as a slider system to meet thermal expansion.

MAKE SURE BOILER PERSONNEL HAVE

BOILER CERTIFICATES!

USE THE BOILER IN COMPLIANCE WITH

WARNINGS AND RECOMMENDATIONS IN

HIS INSTRUCTION GUIDE !

Loading...

Loading...