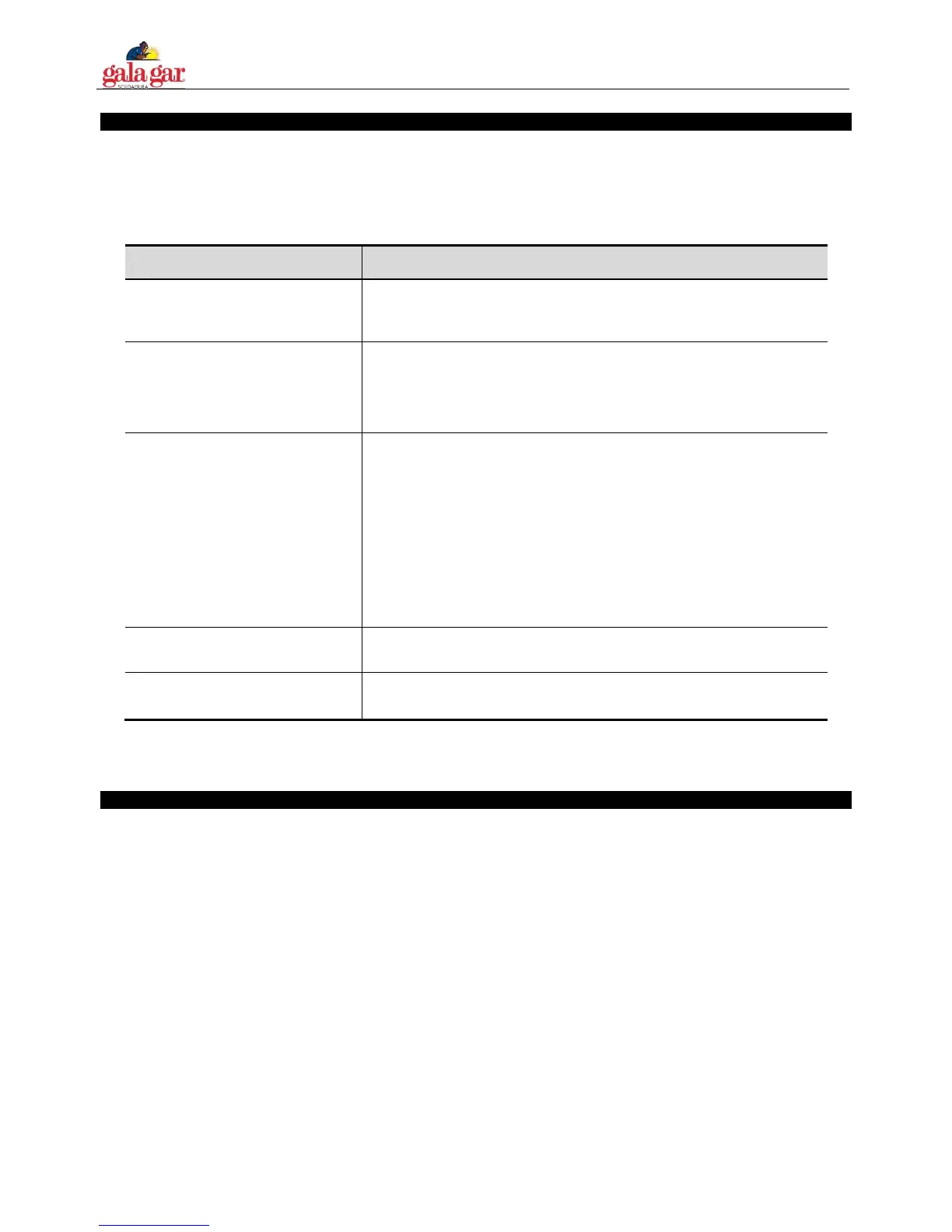

10. TROUBLESHOOTING.

The following operation requires sufficient professional knowledge on electric aspect and comprehensive safety

knowledge. Operators should be holders of valid qualification certificates which can prove their skills and

knowledge. Make sure the input cable of the machine is disconnected from the electricity utility before uncovering

the welding machine

Common Malfunction Analysis and Solution:

Turn on the machine, the power

LED is off, the fan doesn't work,

and no welding output.

(3) Check if the power switch is closed.

(4) No input power.

Turn on the machine, the fan

works, but the output current is

unstable and can't be controlled by

potentiometer when welding.

(3) The current potentiometer fails. Replace it.

(4) Check if any loose contact exists inside the machine. If any,

reconnect.

Turn on the machine, the power

LED is on, the fan works, but no

welding output.

(4) Check if any loose contact exists inside the machine.

(5) Open circuit or loose contact occurs at the joint of output terminal.

(6) The overheating LED is on.

a) The machine is under over-heating protection status. It can

recover automatically after the welding machine is cooled.

b) Check if the thermal switch is ok. Replace it if damaged.

c) Check if the thermal switch is loosely connected, and

reconnect it if necessary.

The electrode holder becomes very

hot.

The rated current of the electrode holder is smaller than its actual

working current. Replace it with a bigger rated current.

Excessive spatter in MMA welding.

The output polarity connection is incorrect. Exchange the polarity.

This product is being improved unceasingly, so differences may appear in parts except for functions and operation.

Thanks for understanding.

Loading...

Loading...