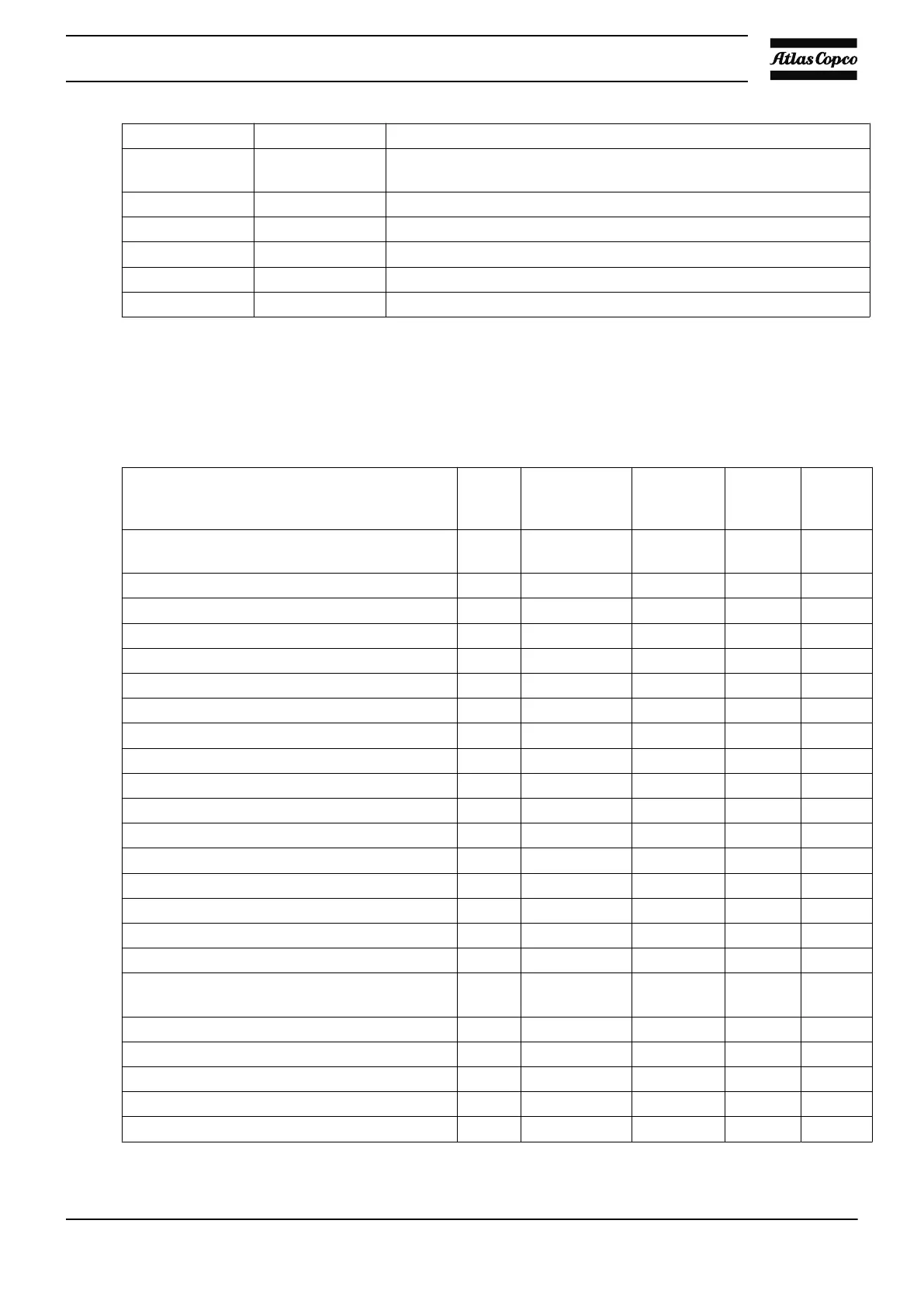

Period Running hours Operation

Daily -- Check the oil level.

Before starting, the level should be in the middle of the sight-glass.

Weekly -- Drain condensate from the air receiver, if installed

Every 3 months -- Clean unit.

Every 3 months -- Check for possible leaks.

Every 3 months 500 Check the cooler; clean if necessary.

When displayed -- Carry out service actions according to the displayed service plans

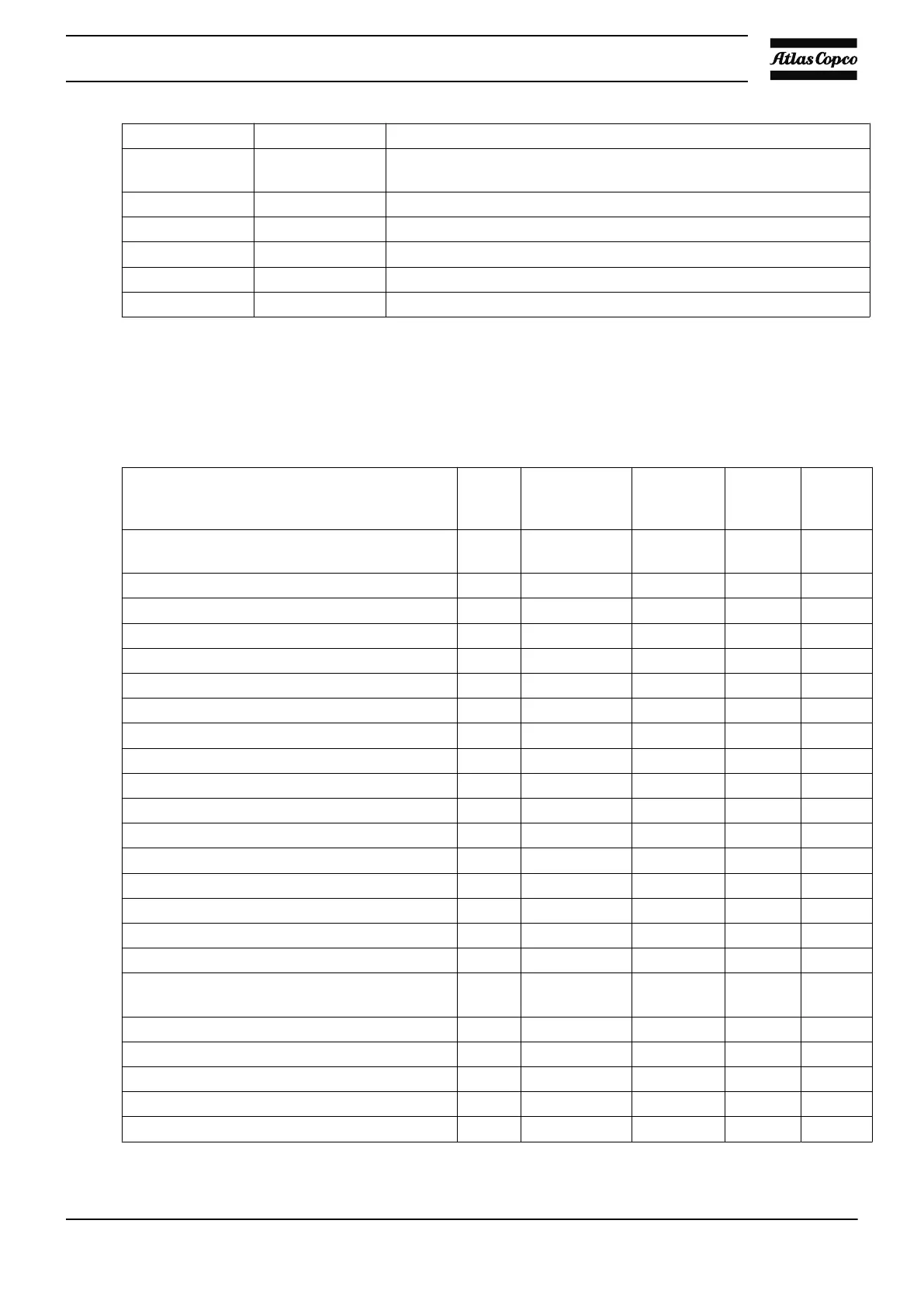

Service plan

A number of service operations are grouped (called level A, level B, level C, ...). Each level

stands for a number of service actions to be carried out at the time intervals programmed. See

part General settings of section Minimum requirements for safe regulation.

Activity 250

hours

500 hours /

monthly

4000

hours / 6

monthly

8000

hours /

yearly

16000

hours /

2 yearly

Take service reading (temperature and

pressure of air, oil and water) X X X X X

Check cooler functionality X X X X

Clean oil cooler block X X X X

Check for air and oil leakage X X X X X

Check sensitive bolt / coupling connections X X X X

Check for presence of water in lube oil X X X X

Change compressor oil X

Change compressor oil filter X X X

Check condition of air intake chamber X X X X

Check air filter element (s) X X X X

Change air filter element (s) X X X

Check filter element of gear case breather X X X X

Replace filter element of gear case breather X X X

Check cycle of start-up / blow-off valve X X X X

Check safety switch X X X X

Check functioning of check valve X X X X

Replace O-rings of check valve X X X

Check the filter mat(s) of the electrical

cabinet(s) X X X X

Replace cubicle filter mats X X X

Grease main drive motor bearings (VSD) X X X

Clean fan cowl of electric motor X X X X

Check rubber inserts of drive coupling X X X X

Replace rubber inserts of drive coupling X

Instruction book

AIF999999 65

Loading...

Loading...