38

4929B–AUTO–01/07

ATA6264 [Preliminary]

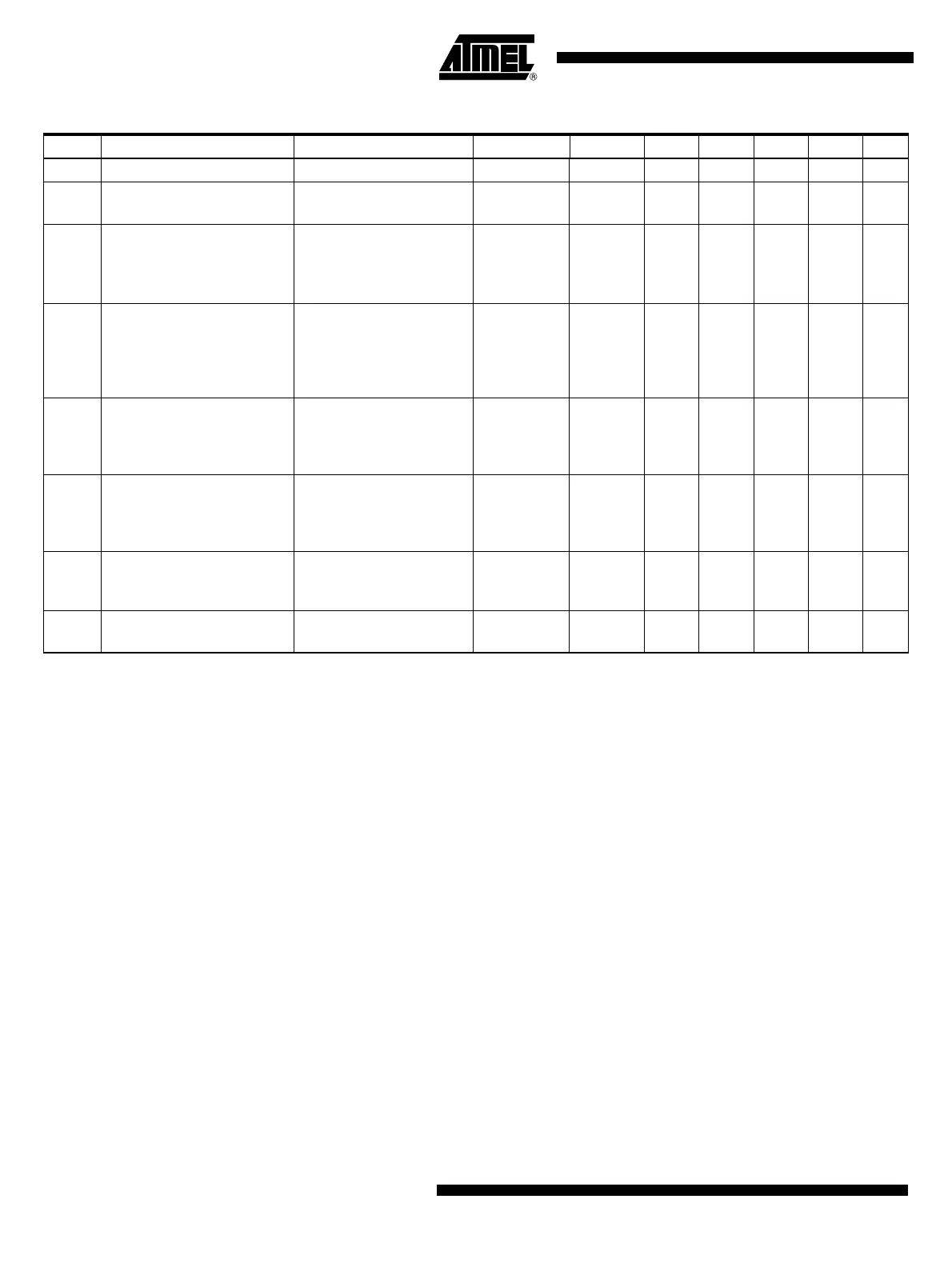

11.25 Leading-edge blanking time t

blank

150 200 ns D

11.26

Slope of artificial ramp for

slope compensation

dV/dt 80

(1)

150

(1)

mV/µs D

11.27

Voltage level at K30 to switch

VCORE supply from EVZ to

K30 (V

VCORE

= 1.8V or 2.5V

programmed)

V

K30

increasing

See number 7.3 of Table

8-2 on page 23

A

11.28

Hysteresis at K30 to switch

VCORE supply from K30 to

EVZ

(V

VCORE

= 1.8V or 2.5V

programmed)

V

K30

decreasing

See number 7.4 of Table

8-2 on page 23

A

11.29

Voltage level at K30 to switch

VCORE supply from EVZ to

K30 (V

VCORE

= 5V

programmed)

V

K30

increasing K30 V

K30

6.1 8.1 V A

11.30

Hysteresis at K30 to switch

VCORE supply from K30 to

EVZ (V

VCORE

= 5V

programmed)

V

K30

decreasing K30 V

K30

0.5 1 V A

11.31

Time to switch VCORE

supply from EVZ to K30 or

K30 to EVZ

SVCORE t

switch

07.6µsD

11.32

VCORE loss-detection

threshold

(2)

VCORE I

Load

01mAD

Table 12-1. Electrical Characteristics (Continued)– VCORE Power Supply

No. Parameters Test Conditions Pin Symbol Min Typ. Max. Unit Type*

*) Type means: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

Notes: 1. Depending on implementation of slope compensation, sub-harmonics have to be prevented.

2. The value of the minimum load current must be higher than the internal pull-up current at pin VCORE to ensure proper

function of the regulator.

Loading...

Loading...