C

A

B

D

E

C

C B E

C

4

5

PAGE 17

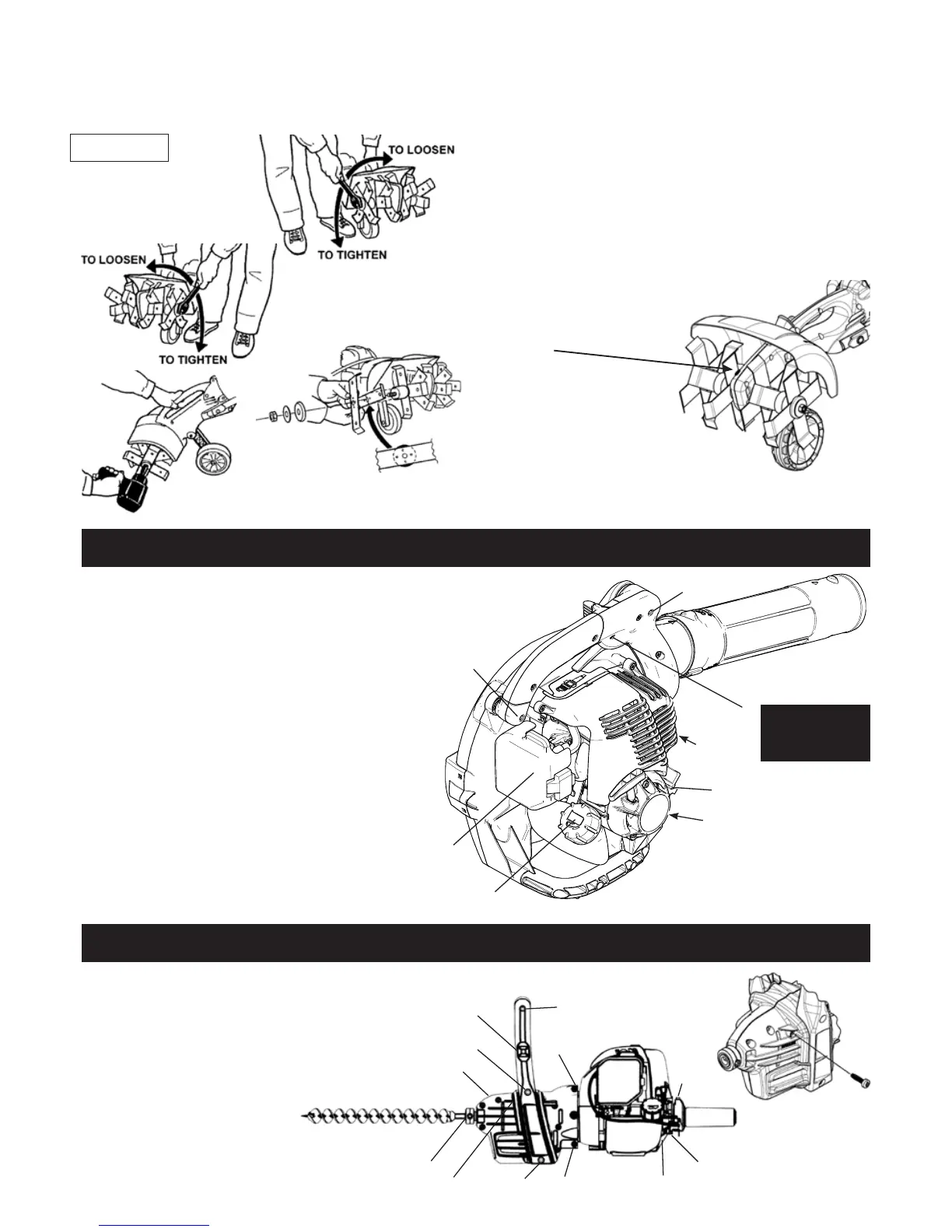

MAINTENANCE: AIRLIFT BLOWERS

1. Check oil level (4-Stroke) with dip stick #1. Also see page 10 Fig.50B.

2. Check regularly the air filter element as per instructions on page 19 #2.

3. Adjust idle speed screw for engine to always have fast idle speed

(for easier starting).

4. Check all screws are tight on RH side of blower.

5. The internal three handle mounting springs can be

checked with Torx20 screwdriver inserted into 3 handle

recess holes #4.

6. Discard carefully any old fuel in tank if unit has not been

used for three months or more #5. Refuel with fresh fuel.

• For 4-Stroke engine use regular gasoline (no oil) and

change sump oil every 50 hours and regularly check

oil level.

• For 2-Stroke engine use regular gasoline with

50 to 1 oil. See page 10.

7. Replace any broken or worn parts

8. Cruise control tension screw adjustment

If you have other service issues see pages 18 to 20

and consult your authorised Atom Dealer.

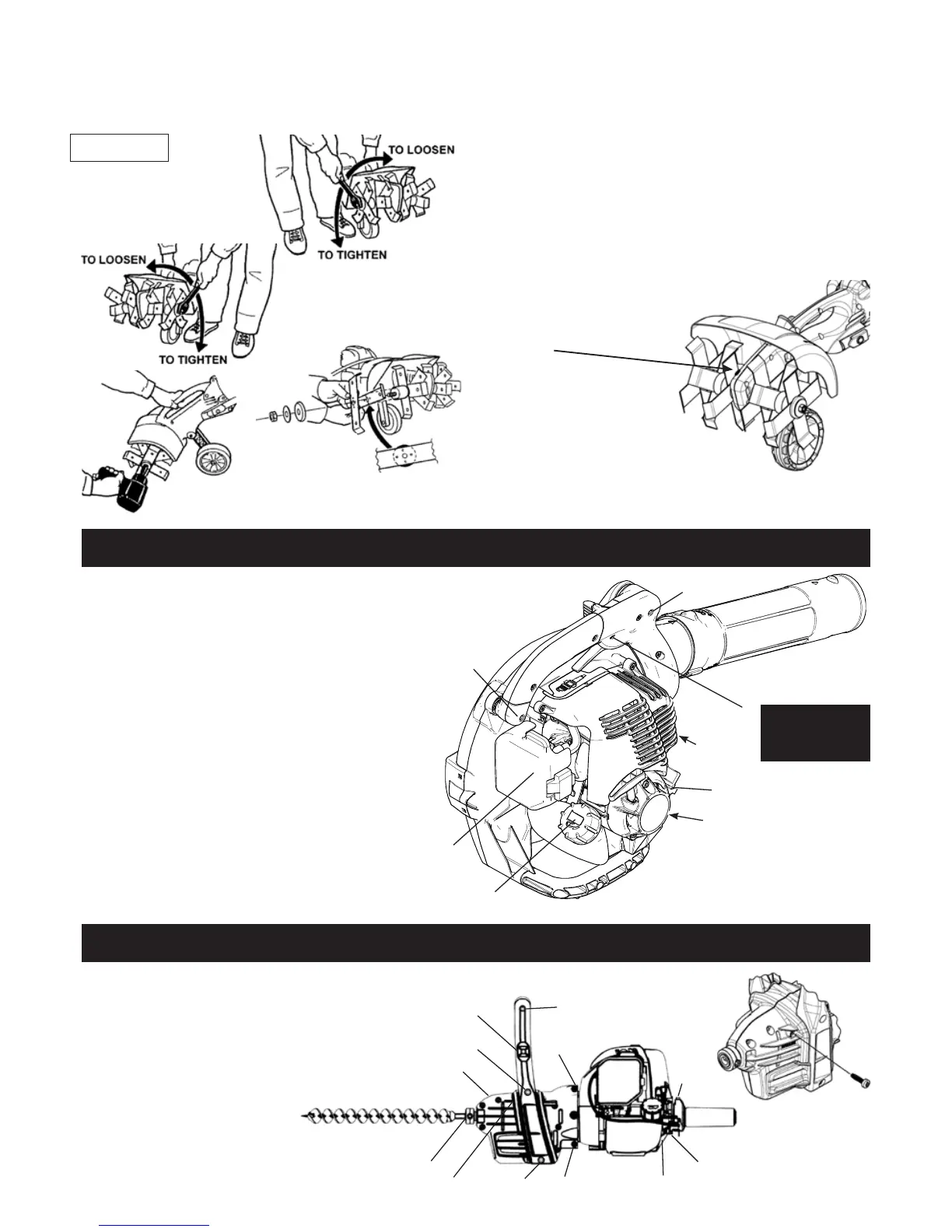

MAINTENANCE: DRILLMASTER ENGINE DRILLS

1. Depending on use, check all Torx25 screws around gear

box (A), engine mount (B), Handles (C). Check various

screws around recoil starter (D). Also check Torx20 screw

(E) that locks throttle cable clamp.

2. Check after starting and warm up engine that idle speed

does not turn auger. If adjustment required see page 19.

3. Check that ignition OFF

SWITCH (E) turns motor off.

4. Ensure grub screw is tight

on auger flat to prevent

auger from loosening.

5. Add grease every 10 hours from grease bottle.

Part No.43327. Minimum three squeezes. Fig. 90.

4

1

5

FIG 88

4

4

FIG 89

! NOTE

LEFT HAND SIDE

(Standing behind tine cover)

NOTE: Tine

assembly sequence.

WARNING: When using air tools to remove nut, do not

overtighten when refitting.

Levelling uneven ground: The tiller if used carefully can level

uneven ground for a good garden bed. Use your arms to work

the tiller forwards and backwards.

After levelling pre-work all surfaces to prepare the new flat bed.

Use a rake to smooth out and tidy up.

The tiller can be transported by pushing it on its wheel.

Very hard ground, clay or rocky conditions: The Atom

rotary tiller is NOT DESIGNED for vary hard ground, hard or

rocky conditions. These kinds of soil will not make a good

garden bed.

FIGS 85

RIGHT HAND SIDE

(Standing behind tine cover)

Tines

are self

tightening. Excessive

tension is not required.

LOOSE TINES

Check that all tines are in correct position and are tight together,

no gaps or foreign material between them. Tighten nut clockwise

on LH side of unit and anti clockwise on RH side (Fig.85) as shown

on top of tine cover.

LUBRICATION OF GEARS

Every 5 hours top up with grease to gear box.

Remove filling screw and inject

grease through hole. Grease

squirts back out of filler hole

when full.

Available in

squeeze bottle.

Part No. 43227.

FIG 84

DO NOT USE

SYNTHETIC BASED

GREASE

FIG 90

GREASE

SCREW

3

2

Use mineral grease (usually with lithium based).

8

Cruise control

tension screw

adjustment

Loading...

Loading...