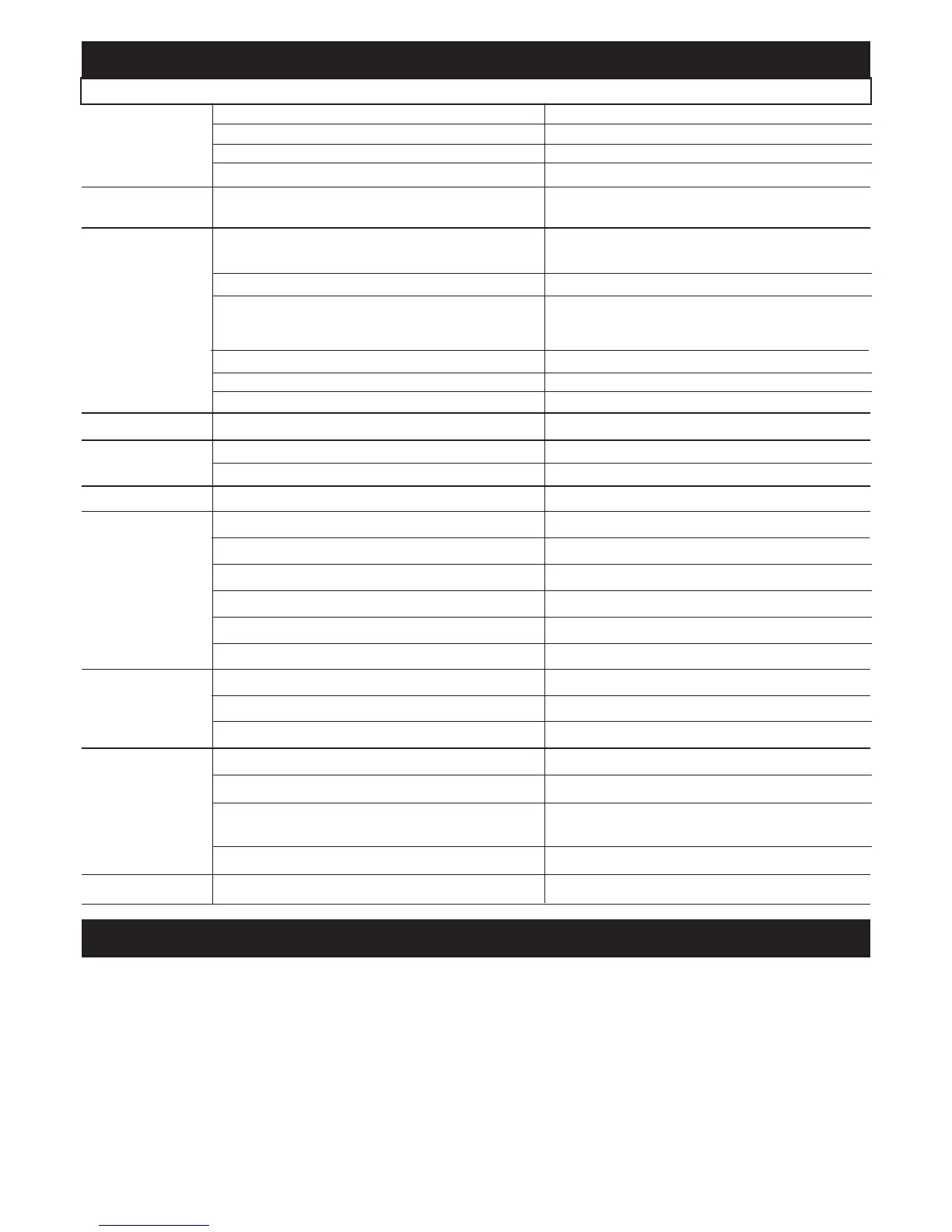

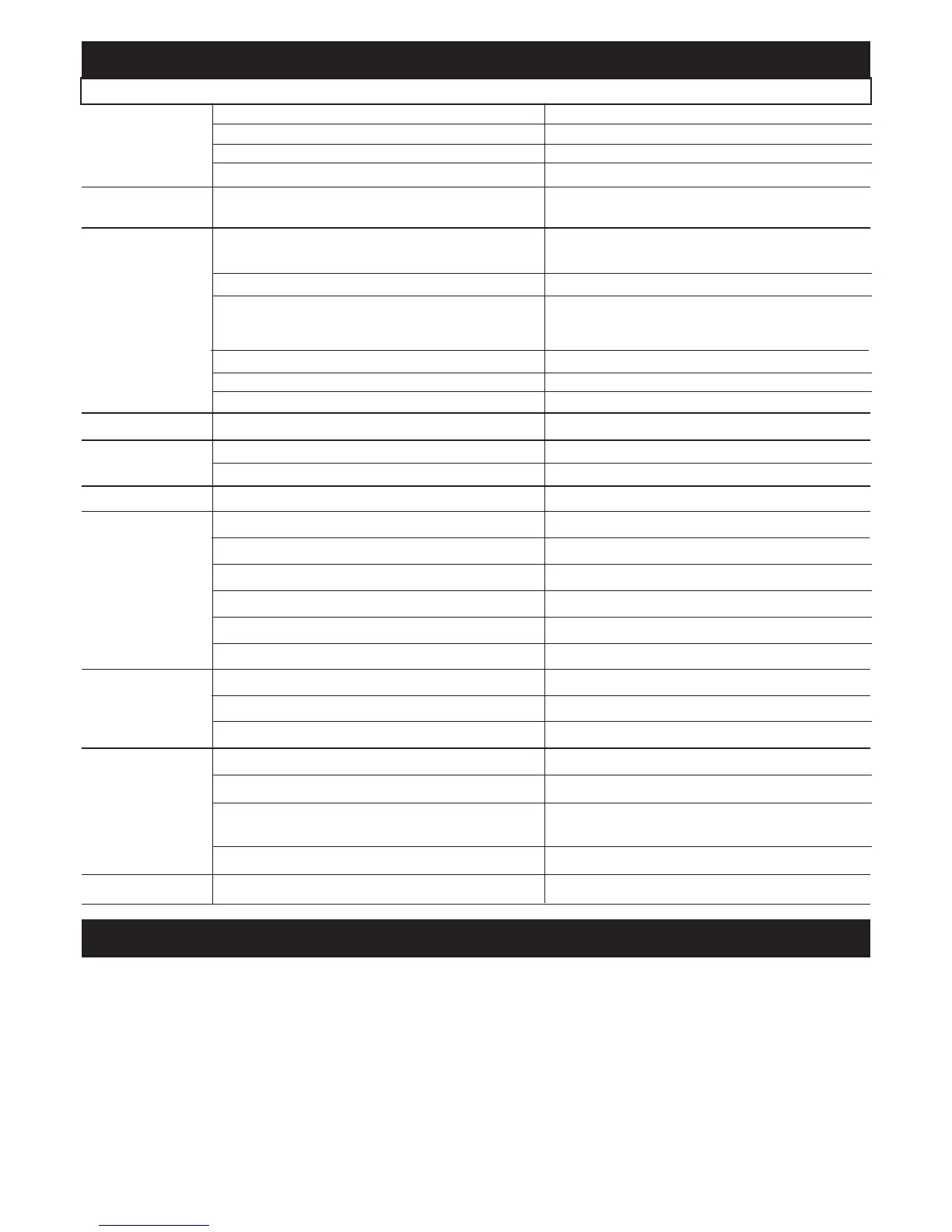

PROBLEM CAUSE ACTION

1. Blades do not turn Loose blade nut or incorrect assembly. Tighten blade nut (or also add washer under nut).

when operating

Blade cover filled with dirt/grass/mud. Clean.

Blade stops under load when blade depth is too deep. Cut less depth. Set wheel arm on 3 or 4.

Clutch slipping can damage clutch and housing. Cut less depth or clean. Set wheel arm on 3 or 4.

2. Motor lacks power or Cutting too deep. Decrease cutting depth and see (1) above.

blade stops rotating

3. Throttle trigger will Throttle cable may need re-adjusting.

Adjust throttle cable by loosening 2 trigger cover screws

not switch motor on and

pulling throttle cable about 2mm out. Retighten screws.

electric

Not connected to power. Reconnect

House Safety switch – earth leakage circuit breaker (Residual Click to ‘ON’. If residual current device continues to cut out,

current device) not on. check cables, house power point or house safety switch

could be faulty.

Faulty extension cord. Replace extension cord.

Motor switch or motor not activating. Take to service dealer.

Motor damaged. Take to service dealer.

4. Hot extension cord Light duty extension cord being used.

Use a heavier gauge/heavy duty extension cord.

5. Heavy vibration Wrong blade fitted. Only use ORIGINAL Atom blade set #43105

Worn clutch or clutch drum or damaged drive. Take to service dealer.

6.

Gear case leaking Loose screws. Tighten.

7. Engine will not run Ignition switch is OFF Ignition switch to be in run position.

or runs and stops

Choke ON Push choke off.

Partially empty fuel tank Fill tank.

Primer bulb not pushed enough times Press primer bulb fully and slowly 10 times.

Engine is flooded Use correct start procedures.

Dirty or blocked fuel or air filter Clean or replace fuel or air filter.

8. Carburettor: If adjustable jets fitted Open jets slightly

If not adjustable Clean carburettor

Dirt in carburettor or old fuel Clean.

9. Edger blades or Edger or tine cover filled with dirt, grass, sticks and rocks Clean.

Tiller cutting tines do

Clutch slipping

Less depth. Check edger blades are spinning or tiller tines rotating

not turn when

operating

.

Loose blade or tine nut, washers missing Check for missing washers. Tighten edger blades or tine nuts

both sides.

Choke partly on Slide choke off.

10. Blower 855 Hard to start (if well used) Replace manifold o-ring.

TROUBLESHOOTING: EDGERS – TILLERS – BLOWERS

TROUBLESHOOTING: AIRLIFT BLOWERS

PAGE 20

There is very little to go wrong with your Atom Airlift Blower.

Follow all instructions including pages 18 and 19. These include:

1. Use good quality 2-Stroke 50/1 oil as 50:1 fuel mix in 2-Stroke

engines ie. 20ml oil to 1 litre petrol or 80ml oil to 4 litres petrol.

2. SAE 10-30W synthetic oil in 4-Stroke engines.

3. Clean and oil air filter regularly depending on use.

4. If storing unit for 3 months or more, drain fuel from tank, restart motor

to use residual fuel in carburettor.

5. Follow regular maintenance chart. Page 18.

6. Starting and idling are covered on Page 19. If well used Honda

engine is harder to start, check o-ring on manifold for o-ring

replacement.

7. Starting difficulties could occur when the idle speed

is not fast. After much use idle speed can drop back. Keep

fast idle speed for easy starting.

8. If Atom engine powered blower does not achieve full RPM, check that

choke is full off and that carby is full on when throttle trigger is pulled

fully up. If necessary adjust throttle cable for full throttle. Otherwise

adjust carby jet.

9. If Honda engine powered blower does not achieve full power, check

that choke is fully open and that carby is full on when throttle trigger is

pulled fully up. Otherwise adjust throttle cable.

Loading...

Loading...