COMPLETE WORKSHOP MANUAL (CONTINUED)

18

!

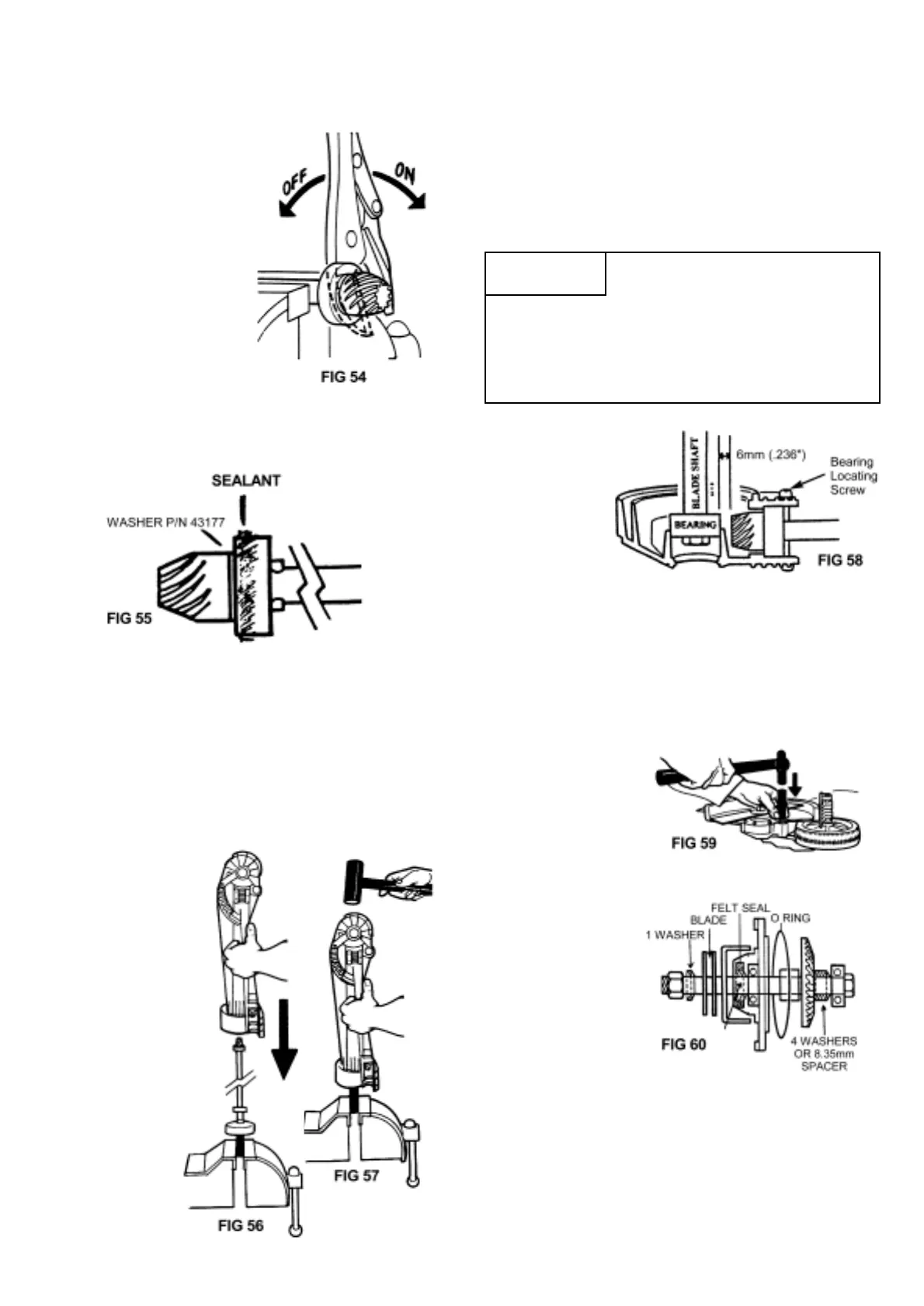

NOTE

Bearing must be forward to

allow bearing locating screw to

be fitted, then pinion and bearing forced back

onto screw. If this is not done, pinion or crown

gear could be tight. Correct distance is 6mm

(.236”) Fig. 58.

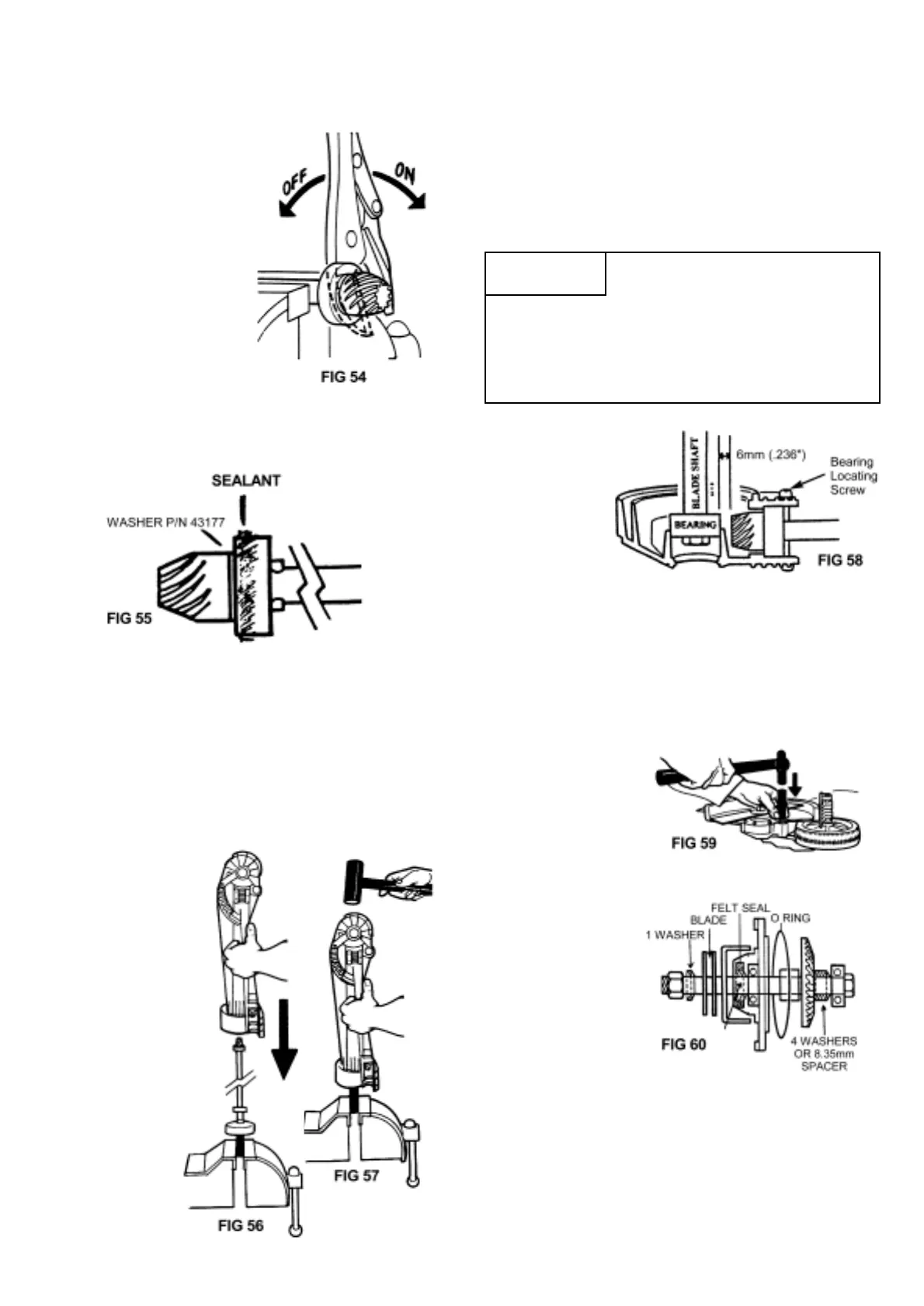

TO REMOVE PINION

1. Hold shaft in vice

between two pieces of

aluminium so as not to

damage shaft.

2. To remove pinion, grip

shaft just behind

bearing in jaws of vice

(Fig. 54) and unscrew

pinion counter (anti)

clockwise (normal

thread) with vice grips.

If tight, heat to break

loctite seal.

3. Fit new pinion with

fresh loctite on thread,

making sure it is tight up to spacer washer

#43229, (Fig. 55) and washer does not move.

4. With a soft hammer, tap casing down until it

bottoms on pinion bearing (Fig. 57).

5. Fit bearing location screw (See Fig. 48 marked A)

and leave nut loose.

6. Using a screwdriver, lever pinion firmly back onto

bearing locating screw and tighten nut (Fig. 52 &

53).

4. To remove clutch drum, grip shaft just behind bearing

in aluminium vice jaws and impact off with 14mm

(9/16”) hex socket. See Page 17 for replacement of

drum.

ASSEMBLING MAIN HOUSING

1. Clean and dry bearing. Place oil resistant gasket

sealant (e.g. Fullerprene 303) around bearing as

in Fig. 55.

2. Place and

lock-up a

15mm

diameter

(approx.)

brass drift

vertically in a

vice (Fig. 56).

3. Hold centre of

clutch drum

nut on top of

drift and slide

main body

housing down

over shaft

(Fig. 56).

7. Replace

crown gear

if teeth are

worn. See

sequence

of assembly

(Fig. 60).

8. Check and

renew O’

ring #40906 if necessary. Fit assembly into

housing. If bearing is loose in housing, smear

loctite around bearing before assembling.

Carefully drive down (making sure gears are

meshing) by gently tapping around bearing area

(Fig. 59) and turning clutch drum. Refit 6 screws

around shaft.

9. Fill or top up with

gear lubricant.

See Page 11

“LUBRICATION

OF GEARS”.

10. Fit blade (see

page 10) and

bearing cap and

check rotation

that gears are

not binding. It

should turn

smoothly from

clutch end.

Backlash at end

of blade about

2-4mm. Refit

blade cover lid,

engine, handles and test.

Loading...

Loading...