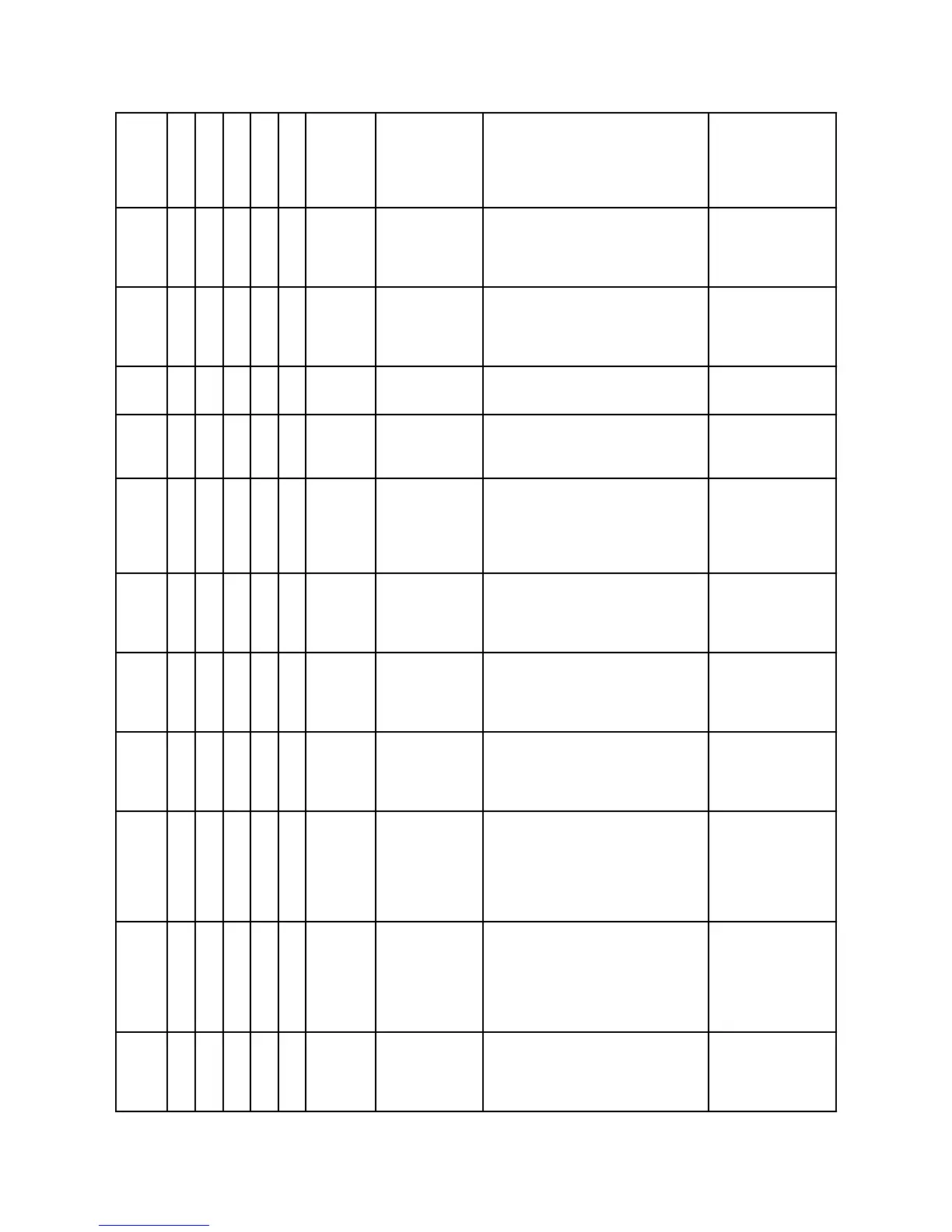

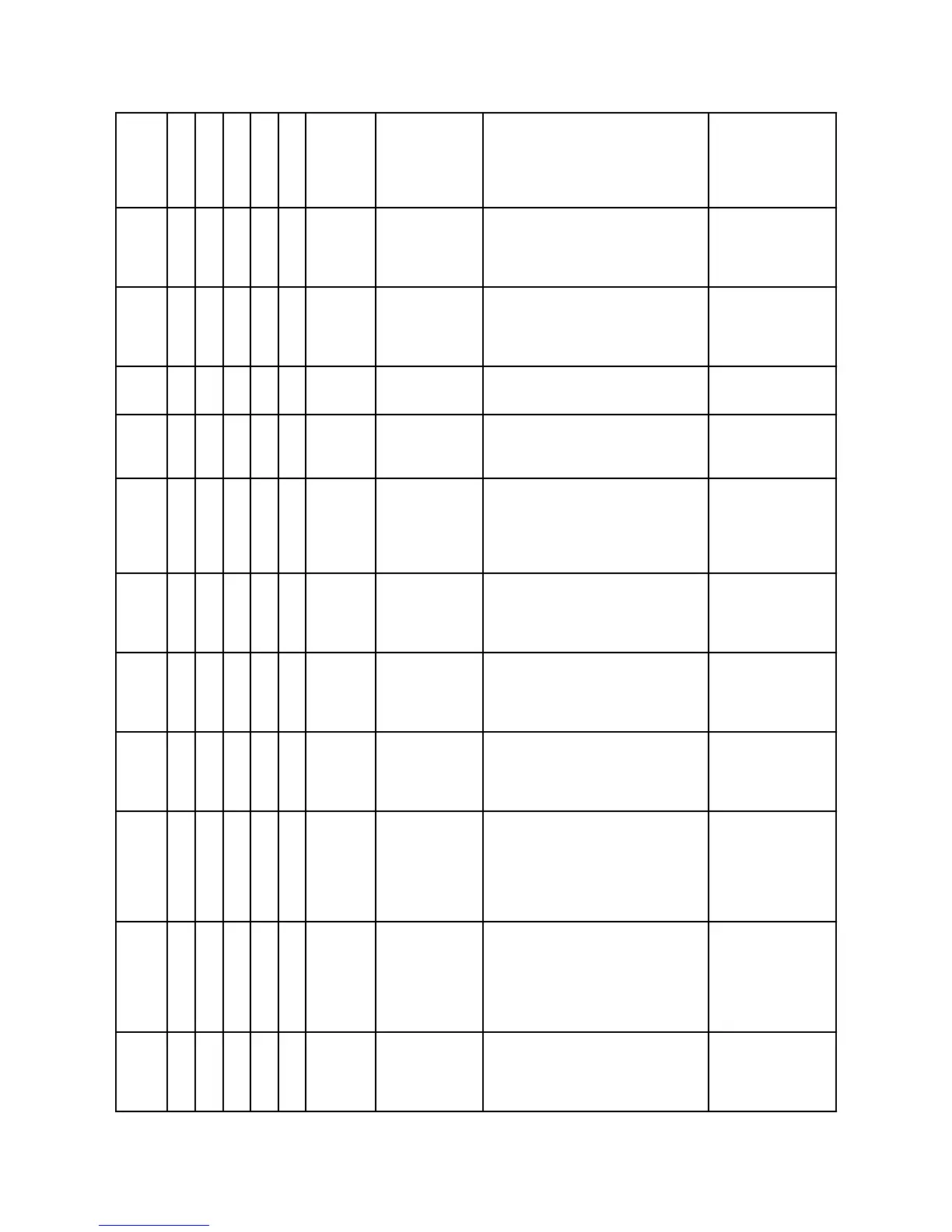

Intake and

Exhaust

Valves

Adjust valve head clearance after

the first 20 hours of operation

and then every 500 hours.

Primary and

Prefilter, Air

Filter

Elements

Replace air filter elements

Check after first 20 hours of

operation and then every 500

hours. Check for loose head

nuts. Torque cylinder head nuts.

Replace every 1,000 hours.

Replace fuel injection pump.

Generator

Set, Engine/

Alternator,

and Control

Panel

Check for damage, corrosion,

missing, or loose attaching

hardware

Damaged,

corroded,

missing, or loose

hardware

Inspect for breaks and/or

damage. Replace damaged fuel

lines.

Fuel lines leak or

show signs

of wear or

damage

Check for damaged, corroded, or

missing fuel fill strainer, tank cap

lug, and retaining rope.

Damaged,

corroded, or

missing

components

Check for damaged flexible

sleeve coupling and flexible

flange couplings

Damaged

alternator

coupling

components

Check for damaged, corroded, or

missing convenience receptacle

and cover (MEP-531A); LOP

engine shutdown cable grommet

and cable guide; and slave

receptacle.

Damaged,

corroded, or

missing control

panel

components.

Check for any lose wiring,

damaged or bruned wires and

insulation on all electrical leads

and harnesses. Ensure that

protective cover on rear of

instrument panel is secure.

Damaged control

panel

components

Check for damaged or corroded

load terminals, electrical outlets,

plugs and any fasteners.

Damaged or

corroded load

terminals or

receptacles

AGI6500DE & AGI6500SDE Operator / Owners Manual Version 11.4.1

Page 25

Loading...

Loading...