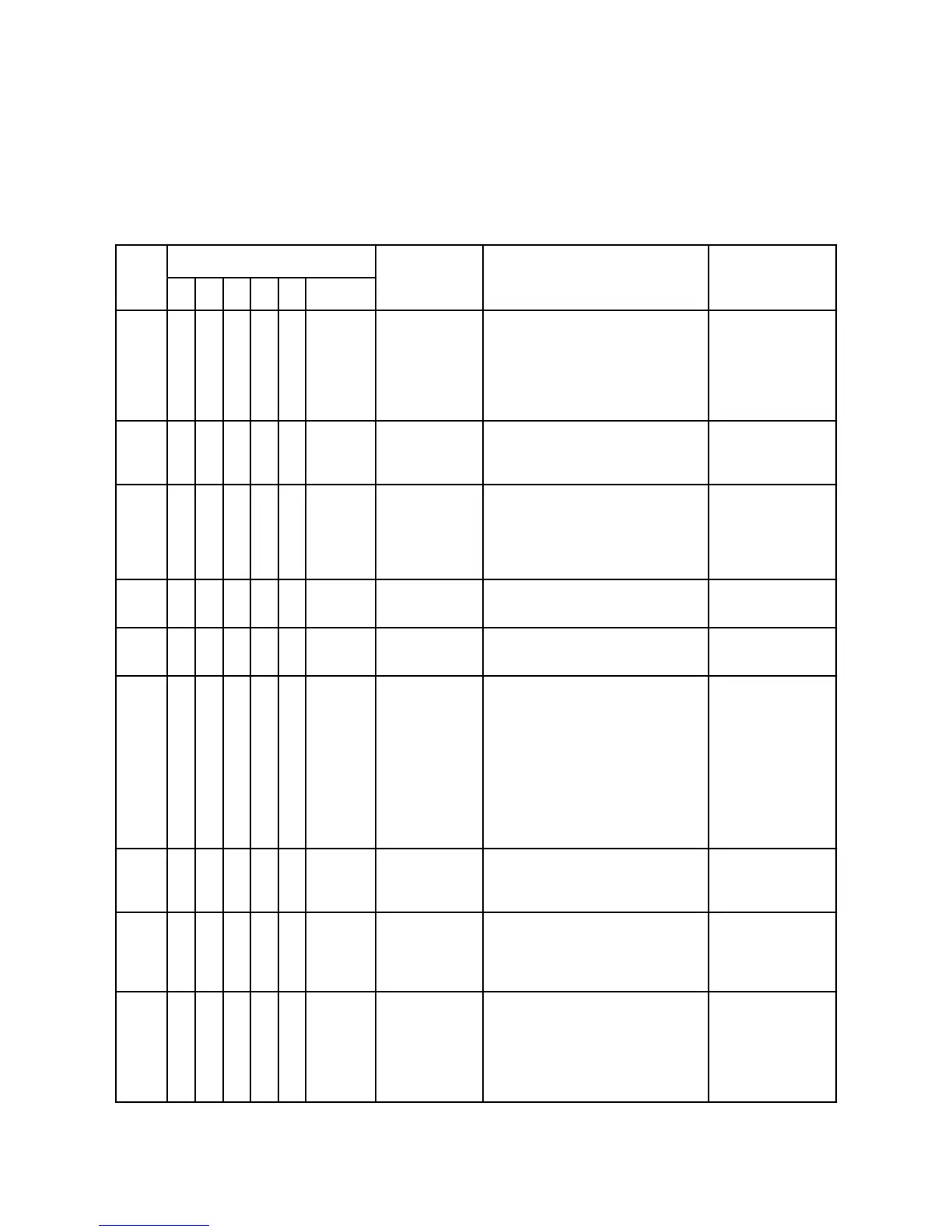

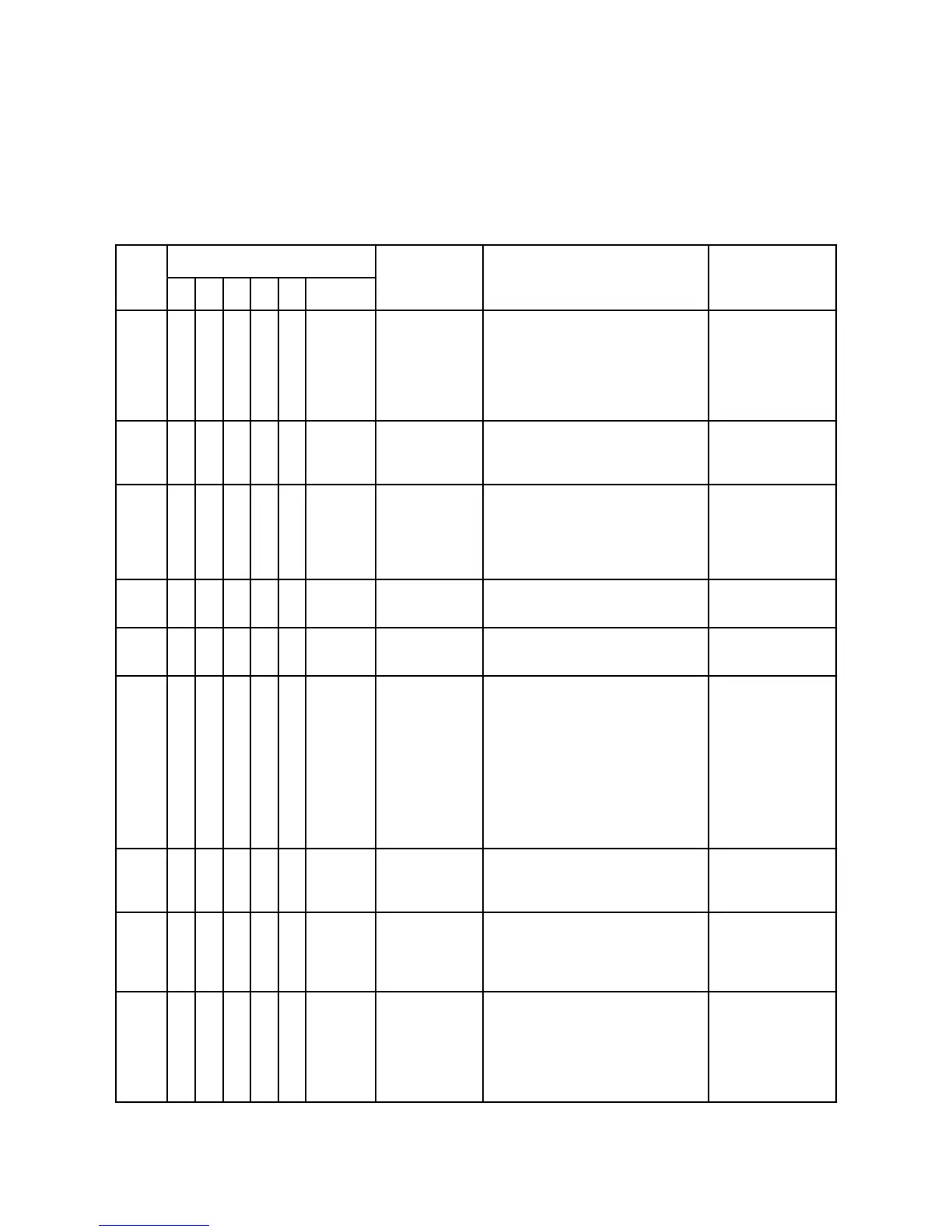

PREVENTIVE MAINTENANCE

CHECKS AND SERVICES

Within designated intervals, these checks are to be performed in the order listed.

M-Monthly Q-Quarterly S-Semi-annually A-Annually B-Bi-annually H-Hourly

Generator should

not be used if

Generator should

not be used if

Check for loose, damaged, or

missing parts. Tighten loose

parts. Repair or replace damaged

or missing parts. Inspect

decompression lever for debris.

Clean if needed.

Engine parts are

loose, damaged,

or missing.

Check battery terminals are

secure. Recharge battery if not

in use.

Primary and

Pre-filter Air

Filter

Elements

Inspect for clogged primary

(paper) air filter element. Clean

every 50 hours or as required, or

replace element if damaged.

Replace pre-filter (foam) element.

Air cleaner

element is

clogged or

damaged.

Check for damage or corrosion.

Check for any loose hardware or

corrosion.

Change diesel engine oil after the

first 20 hours of operation and

then after every 100 hours. (1)

Remove diesel engine oil drain

plug and collect oil in an

appropriate chemical resistant

container for disposition/disposal.

Remove, clean, and install oil

strainer. Add proper lube oil.

15W40 Synthetic

Replace fuel filter element.

Inspect gaskets for damage

Check for damaged, missing or

corroded spark arrestor if

present.

Alternator

Brushes

Wires and

Holders

Check for worn alternator

brushes. Length must be a

minimum of 0.5 in. (1.3 cm).

Check for damaged or missing

brush caps, wires, and holders.

Alternator

brushes worn.

Damaged or

missing brush

caps, wires, and

holders

AGI6500DE & AGI6500SDE Operator / Owners Manual Version 11.4.1

Page 24

Loading...

Loading...