Introduction

vii

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the pack-

aging as well, the feedback lever is detached from the body of

the device when it is packed. As a result, the feedback lever

must be attached to the body of the device prior to installa-

tion of the device.

The length of the feedback lever can if necessary be adjusted

by attaching the extension lever between the feedback lever

and the body of the device. Adjustment of the feedback lever

length is determined based on the form of the actuator.

If the actuator type is speci-

fied when ordering, and the

extension lever is included:

Attach the extension lever to the

body of the device, and then attach

the feedback lever.

If the actuator type is speci-

fied when ordering, and the

extension lever is not in-

cluded:

The extension lever is not neces-

sary. Attach the feedback lever

directly to the body of the device.

If the actuator type is not

specified when ordering:

The extension lever will be in-

cluded. Refer to the table below to

determine, based on the actuator

with which the device is equipped,

whether or not the extension lever

is necessary.

Manufacturer Extension Lever Actuator Type Code

Azbil

Corporation

Yes

VP5, 6, 7 Y1

SLOP560, 1000, 1000X Y2

SLOP1500, 1500X Y3

DAP560, 1000, 1000X Y4

DAP1500, 1500X Y5

(SLOP type and DAP type are limited to products with stroke of

100 mm or less)

When connecting an actuator other than those in the table,

connect the device and the actuator, and then, via manual

operation, move the actuator slowly and ensure that the feed-

back lever does not interfere with a full stroke of the actuator.

If the feedback lever alone cannot cover a full stroke, attach

the extension lever to it.

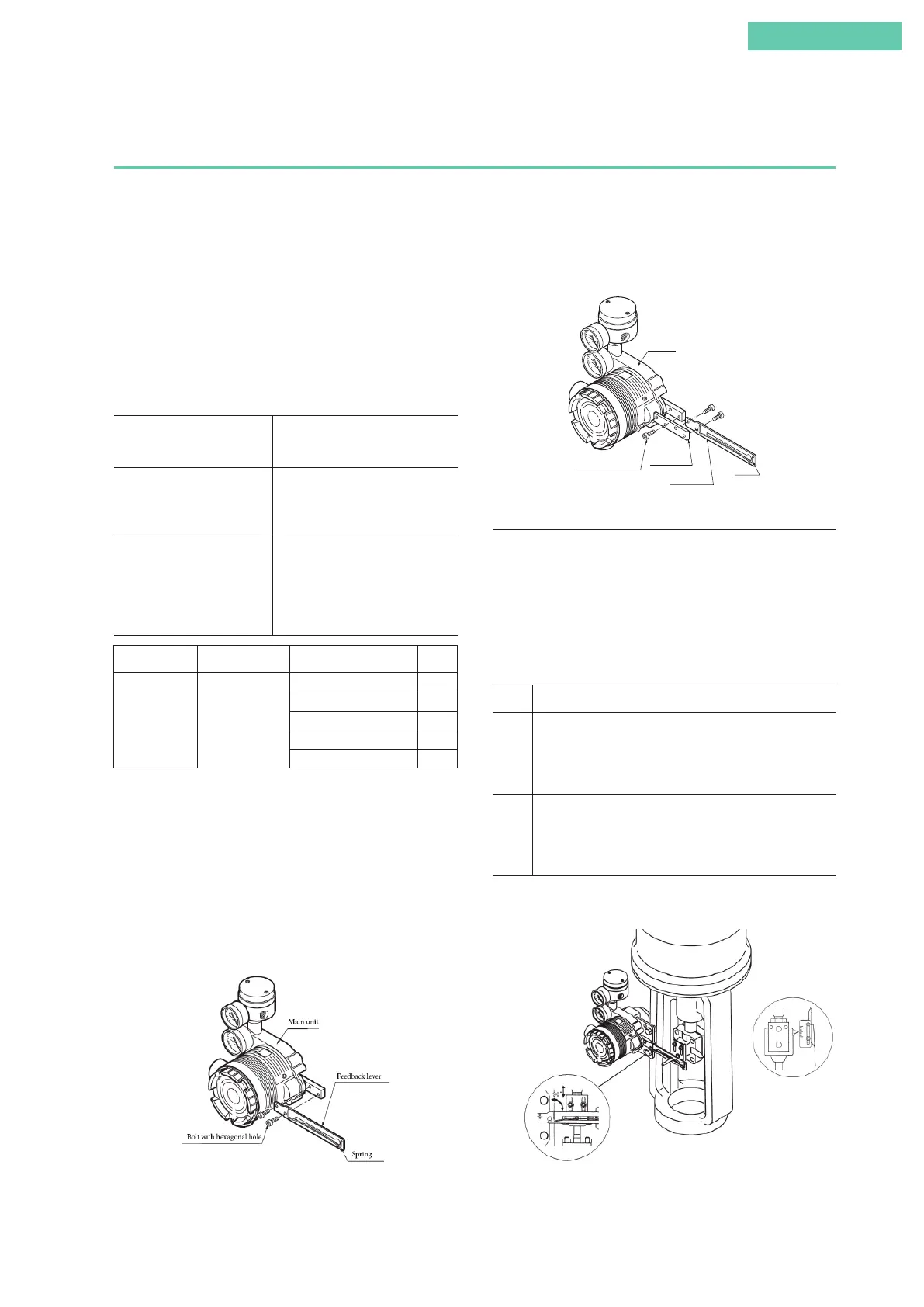

Attach the feedback lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Attachment of Feedback Lever

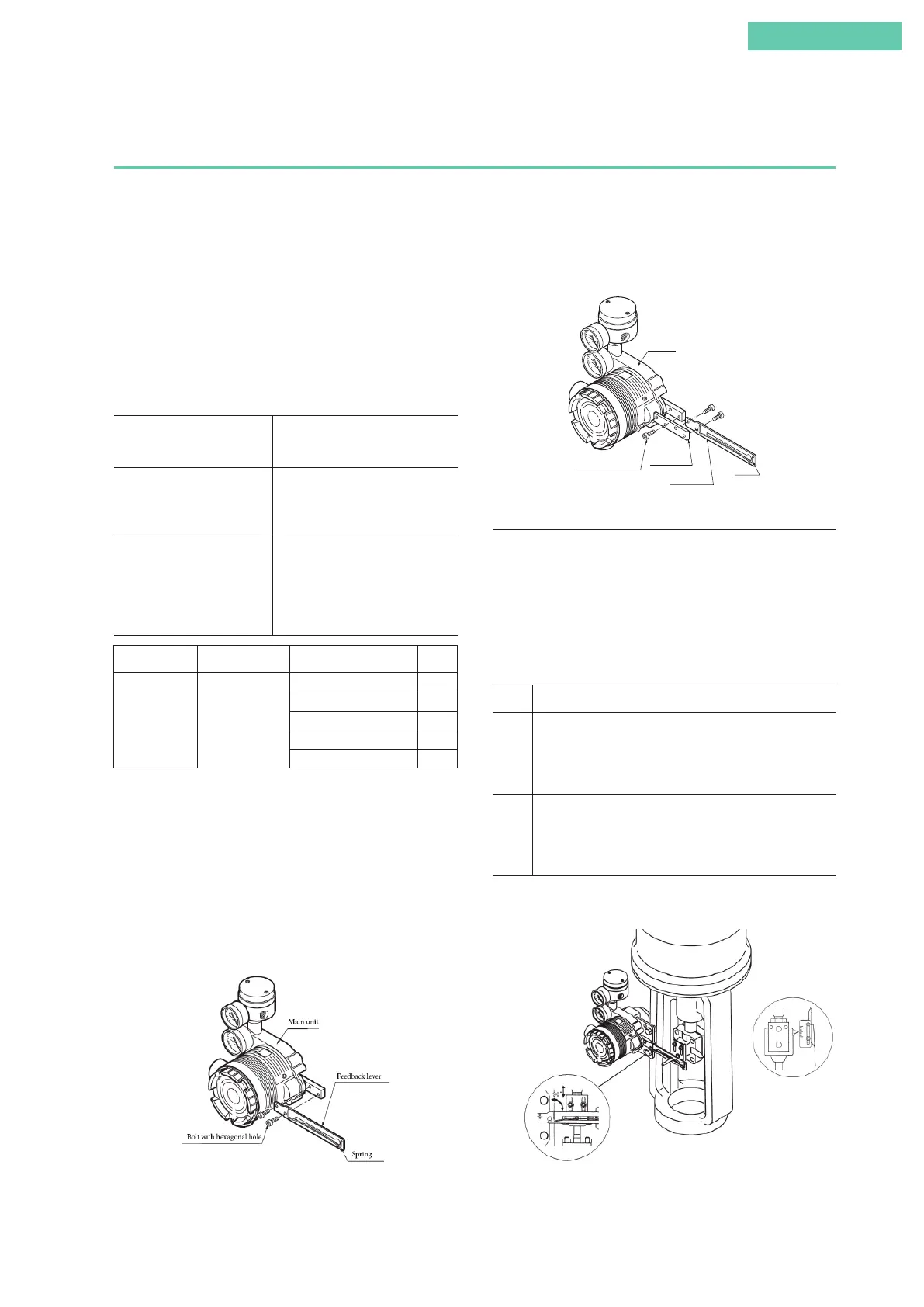

Combination of model AVP300/301/302 (integral type) and double-acting linear cylinder

actuator

Attach the extension lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Then, in the same way, attach the feedback lever securely,

working from the back of the device. (The feedback lever can

be attached from the front as well.)

Main unit

Bolt with hexagonal hole

Spring

Feedback lever

Extension lever

Attachment of Extension Lever and Feedback Lever

2. Attachment and installation

[1] Attachment to the actuator

Attach to the actuator with a mounting plate that is appropri-

ate for the actuator.

[2] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Using for example the manual handle of the actuator

or manual operation via the external pressure regulator

with filter, set the position to 50%. (With a double-acting

actuator, manual operation cannot be performed using the

A/M switch.)

2 Adjust the actuator such that the feedback lever reaches a

90° angle to the device's central vertical axis. Depending on

the actuator being used, adjustment may be performed by

moving the device, or it may be performed by moving the

pin.

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ±2°.

Adjustment of Attachment Positions

Loading...

Loading...