2-7

Chapter 2: Installation

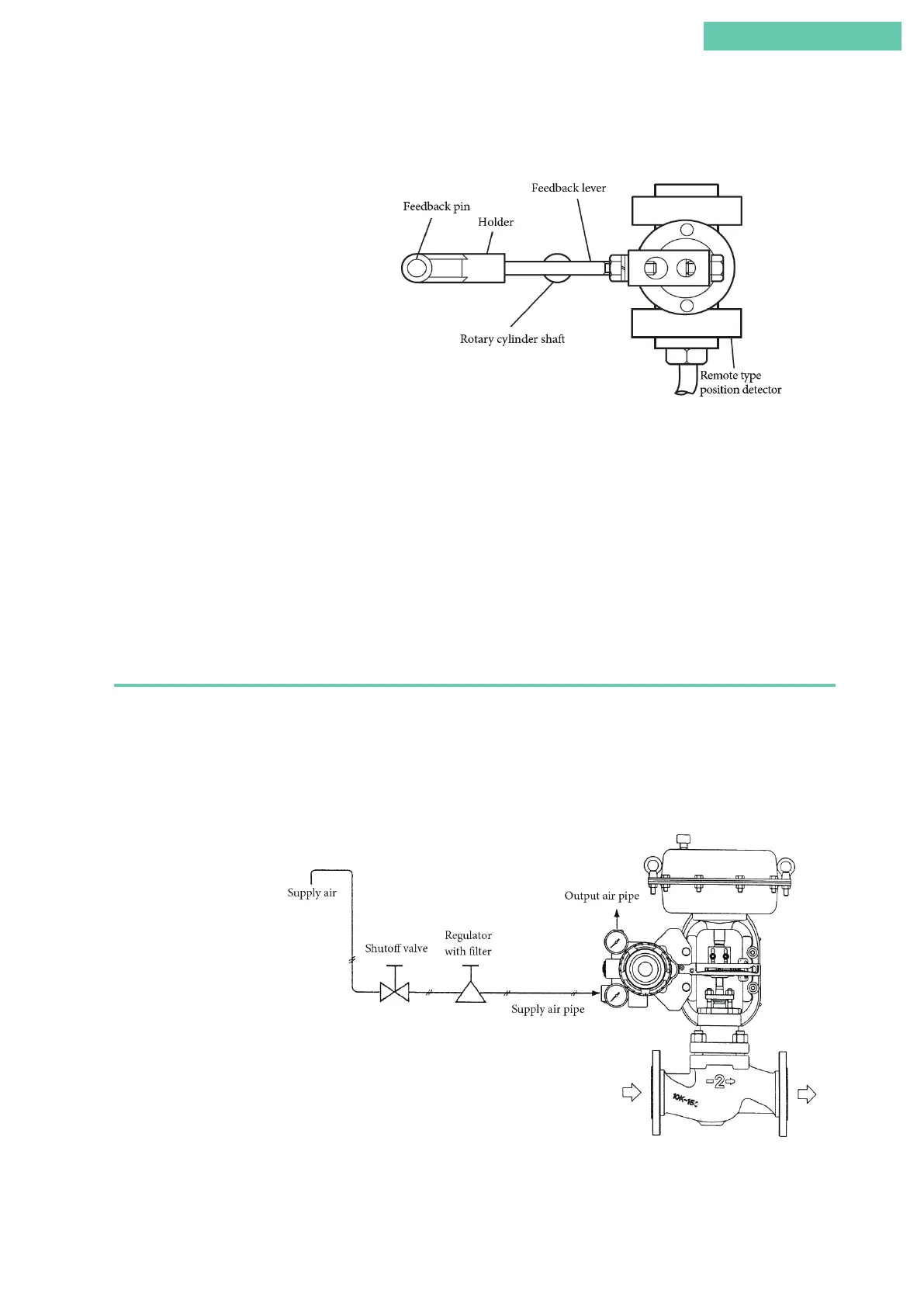

(5) If attaching a rotary cylinder, attach it so that the rotary cylinder shaft comes be-

tween the feedback pin and the device.

Figure 2-5. Connection of Remote Type and Rotary Cylinder’s Feedback Pin and Feedback Lever

■ Rear maintenance space

The device has a flapper nozzle mechanism at the rear of the main unit. The device is

designed such that, when cleaning the flapper, the flapper nozzle mechanism can be ac-

cessed by removing the pilot relay cover at the back of the main unit.

Before mounting the positioner on the actuator, consider a design for the mounting

bracket and feedback mechanism that leaves sufficient maintenance space for the pilot

relay cover, which is secured by three screws, to be removed, and for the work described

above to be carried out.

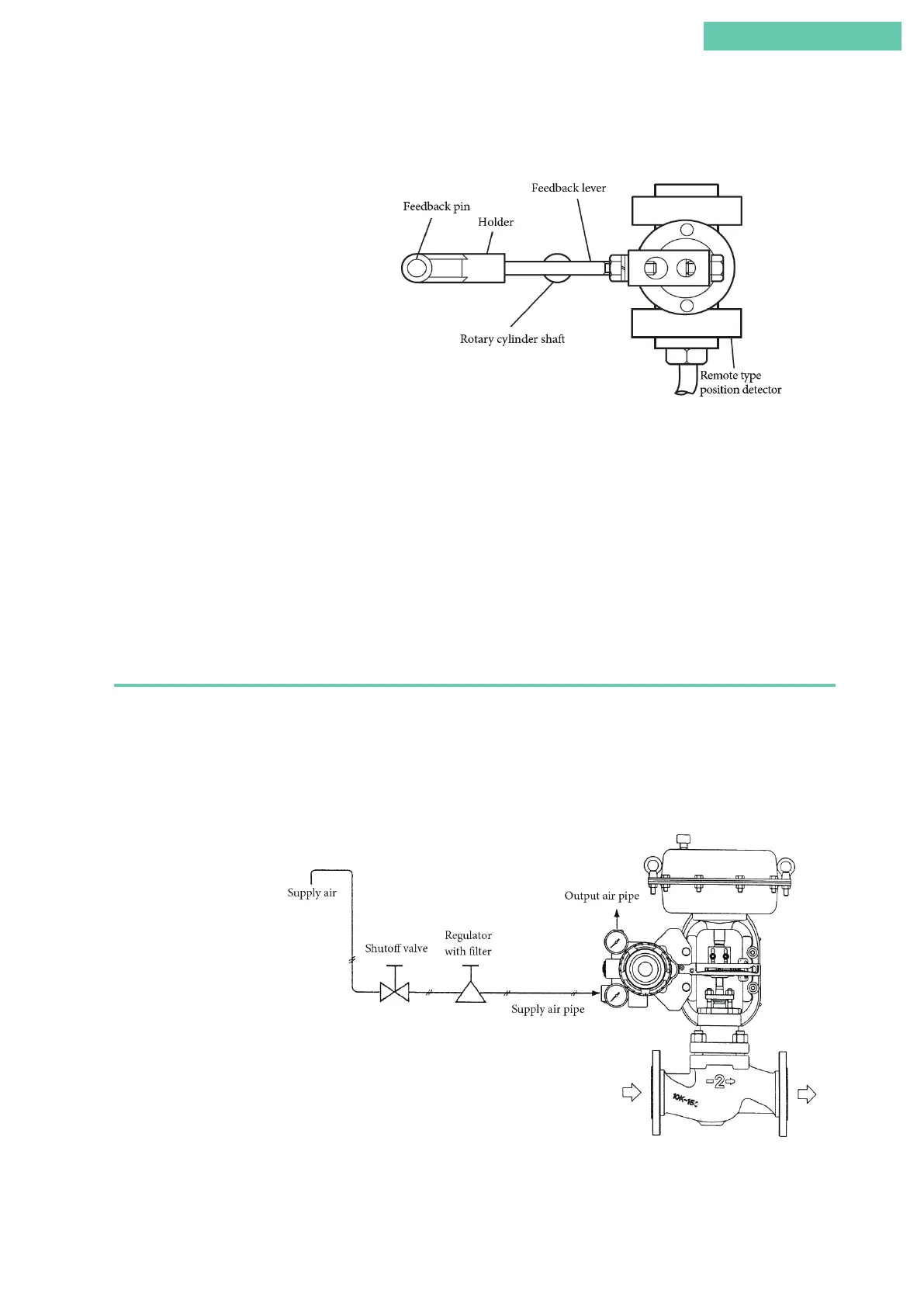

2.2.2 Air piping connection

The method for supplying air to drive the actuator of this device will now be described.

■ Air supply system

In order to ensure safe long-term use of this device, the supply air must be clean and

dry. A typical air supply system is shown in the diagram below.

Figure 2-6. Air Supply System

Loading...

Loading...