Thank you for purchasing our proximity sensor.

This manual contains information for ensuring correct

and safe use of this product.

Please read and understand the manual thoroughly

before using this product, and keep the manual nearby

after installation for handy reference.

Please read the "Terms and Conditions" from the

following URL before ordering or use:

http://www.azbil.com/products/bi/order.html

2004-2013 Azbil Corporation All Rights Reserved.

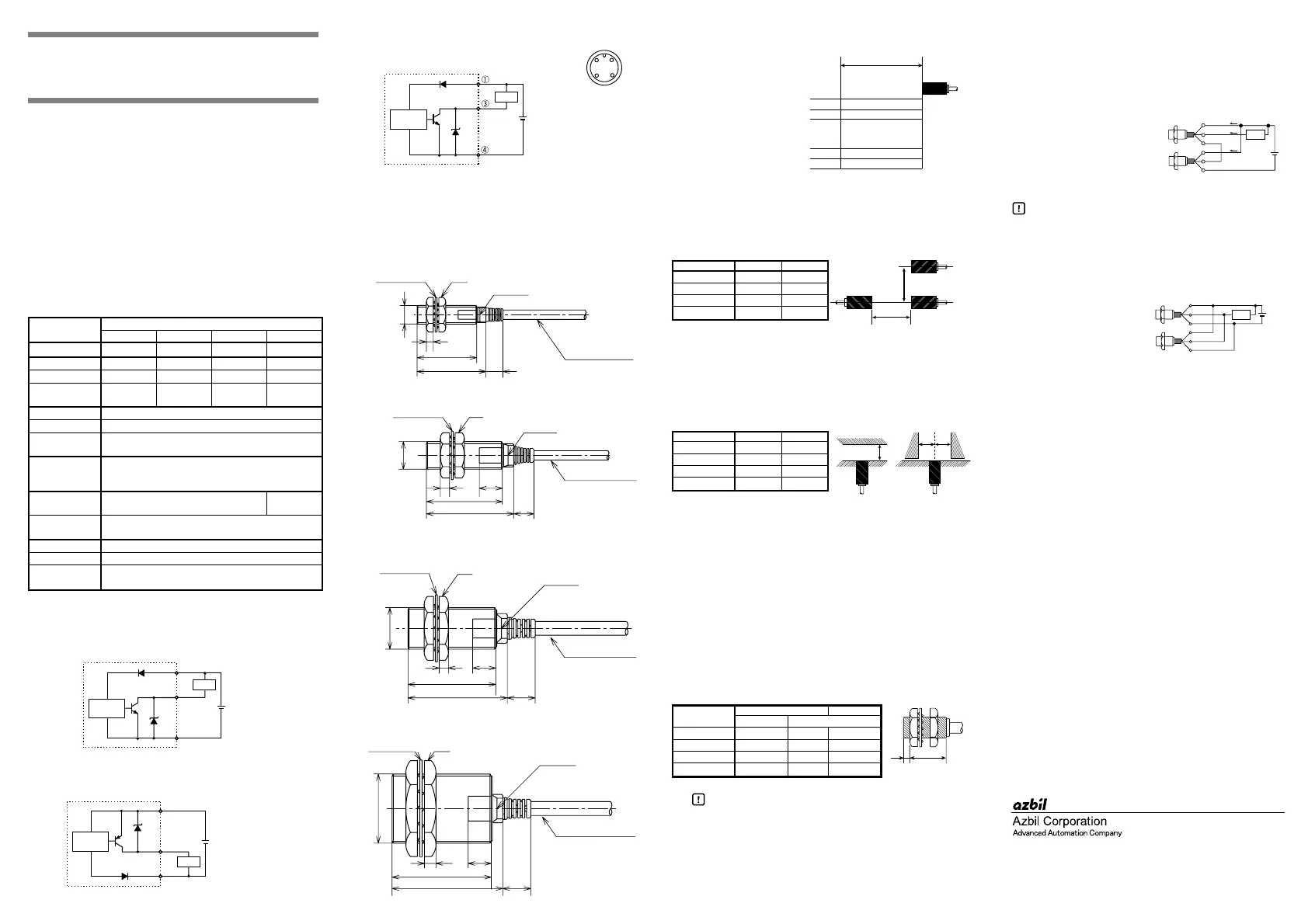

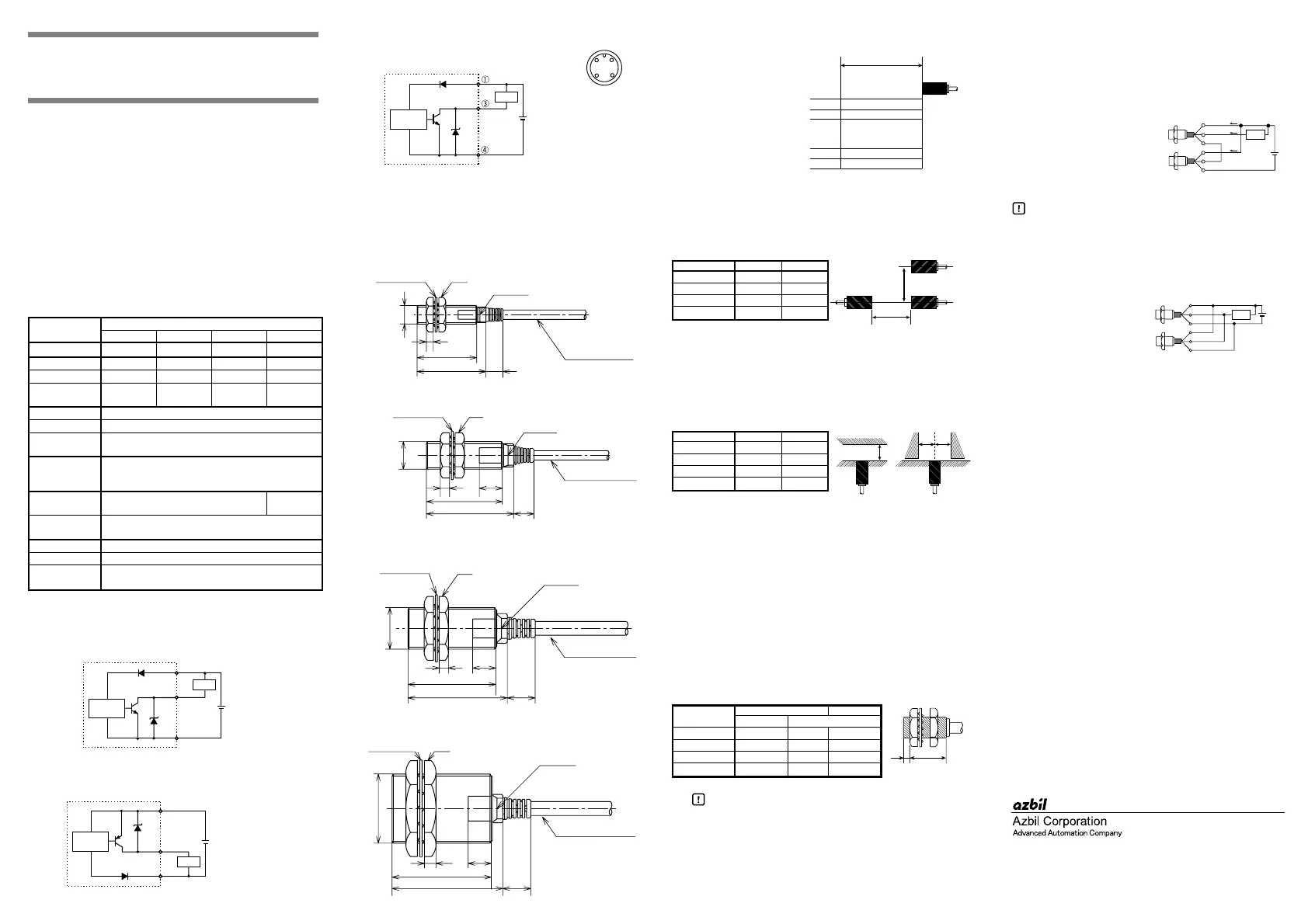

■ Specifications

Shielded type proximity sensor (suitable for flush mounting

onto metal)

■ Circuit and Wiring

● Pre-wired type (NPN) FL7M-_A/B_

● Pre-wired type (PNP) FL7M-_D/E_

● Pre-wired connector type (NPN)

FL7M-1P5A6-CN03

•A load must be used when power is applied to the sensor.

•A combination of short circuit and wrong wiring will cause

permanent damage, regardless of short-circuit protection.

• When connecting a connector fasten tightly by hand.

■ Dimensions

● FL7M-1P5_6_

● FL7M-2_6_

● FL7M-5_6_

● FL7M-10_6_

■ Operating Chart for Output and Indicator

■ Mutual Interference

Erroneous operation due to mutual interference is caused when

sensors are installed in parallel or facing each other.

Separate the sensors by at least the distance specified in the

table below.

■ Influence from Adjacent Metal

Metals opposite the sensor's sensing face must be removed to

avoid false actuation.

Keep metals away from the sensors as specified below.

Shaded areas indicate surrounding metal other than the target

object.

A : Distance between front of iron plate and sensing face of

proximity sensor.

B : Distance between side of iron plate and center of proximity

sensor sensing face.

■ Tightening Torque

● When a nut is used

The permissible torque is different depending upon the

distance from the top of the sensor head. Tighten the body at

less than the maximum permissible torque shown below,

and always with the enclosed nuts and washers.

The tightening torque varies depending on the mounting

plate or housing, the nut and washer material, and the

condition of the mounting surface. Check that the torque is

suitable for the actual combination of items before use.

Handling Precautions

• Do not tighten the body by applying torque to the

indicator unit (plastic unit).

• Do not mount the body using a setscrew. Doing so

might damage the sensor.

■ AND Connection (Serial Connection)

When connecting two sensors in series, please pay attention to

the following:

• Maximum output current (100mA) ≥ load current + current

consumption (13mA)

• Supply voltage ≥ operation voltage of a load + 2 x voltage

drop (2V)

• If target moves too quickly,

sensor may operate incorrectly.

• In series, sensor A may operate

incorrectly on startup, because

sensor A is supplied power from sensor B's output.

Handling Precautions

• With serial connections the sensor may be briefly

unusable due to power fluctuation. Check the

system before use.

■ OR Connection (Parallel Connection)

Up to three of these sensors may be connected in parallel.

■ Points to be Aware of When Handling

• Do not swing the sensor by the cable.

• Do not pull the cable with excessive force.

• Do not use the sensor outdoors, or where it is surrounded by

chemicals (solvents, acids, alkalies, etc.).

• If bending the cable, keep R (the radius of the bend) ≥ (the

cable diameter) x 3 at least.

• When disposing of an FL7M Series switch, dispose of it

appropriately as industrial waste in accordance with

applicable bylaws and regulations.

■ Wiring cautions

• Route the wires of the sensor separately from power lines or

through an exclusive conduit. Otherwise, electrical noise or a

surge may cause faulty operation or damage.

• If an extension of the cable is necessary, use at least a

0.3mm

2

wire of 100m maximum length.

• When using a commercial switching regulator, ground the

FG (Frame Ground) and G (Ground) terminals. Otherwise,

switching noise may cause faulty operation.

• When using a load to generate a transient current, connect a

current limit resistor between the load and the output

terminal. (Otherwise, the short-circuit protection may be

activated.)

Proximity Sensors FL7M Series

(3-wire DC Type)

User's Manual

CP-UM-5373E

Model number

FL7M-

1P5_6_ 2_6_ 5_6_ 10_6_

Size M8 M12 M18 M30

Sensing distance 1.5mm 2mm 5mm 10mm

Setting distance 0 to 1.05mm 0 to 1.4mm 0 to 3.5mm 0 to 7mm

Standard target

8 x 8 x 1mm 12 x 12 x 1mm18 x 18 x 1mm 30 x 30 x 1mm

(steel)

Hysteresis 10% max. of sensing distance

Supply voltage 10 to 30Vdc

Current

13mA max.

consumption

Output Load current: 100mA max.

Voltage drop: 2V max.

Withstand voltage: 30V max.

Operating

-25 to +70°C -10 to +60°C

temperature

Insulation

50MΩ min. (500Vdc)

resistance

Dielectric strength 1000Vac 1min

Sealing IP67 (IEC Standard)

Circuit protection Surge voltage protection, reverse polarity protection,

short circuit protection

Load

Brown

Black

10 to 30Vdc

Blue

+V

0V

OUT

NPN

10 to 30Vdc

+V

0V

OUT

PNP

Load

Brown

Black

Blue

10 to 30Vdc

+V

0V

OUT

NPN

Load

Connector

face view

12

34

30

26

M8 x 1

3

7

Nut

Indicator

Tooth washer

Vinyl insulated cable

(4 dia. 0.3mm )

2

Unit: mm

M12 x 1

938

33

104

Nut

Indicator

Tooth washer

Vinyl insulated cable

(4 dia. 0.3mm )

2

M18 x 1

1243

38

4 10

Nut

Indicator

Tooth washer

Vinyl insulated cable

(6 dia. 0.5mm )

2

5 10

43

48 12

M30 x 1.5

Nut

Indicator

Tooth washer

(6 dia. 0.5mm )

2

Vinyl insulated cable

OFF

OFF ON

RED OFF

ON OFF

Sensing distance

RED

Proximity

Sensor

Indicator

Output

Indicator

Output

FL7M-_A/D6_

(N.O.)

FL7M-_B/E6_

(N.C.)

B

A

A(mm) B(mm)

FL7M-1P5_6_ 15 20

FL7M-2_6_ 20 30

FL7M-5_6_ 35 50

FL7M-10

_6_ 70 100

B

A

B

A(mm) B(mm)

FL7M-1P5_6_ 4.5 6

FL7M-2_6_ 89

FL7M-5_6_ 20 13.5

FL7M-10

_6_ 40 22.5

Part A Part B

Distance (mm) Permissible torque (N•m)

FL7M-1P5_6_ 9912

FL7M-2_6_ 0-20

FL7M-5_6_ 0-70

FL7M-10

_6_ 0-180

PartBPartA

Load

+

+

-

-

OUT

OUT

i

iL

i

Vs

A

B

OUT

OUT

Vs

Load

+

+

-

-

Specifications are subject to change without notice. (09)

1-12-2 Kawana, Fujisawa

Kanagawa 251-8522 Japan

URL: http://www.azbil.com

1st edition: Sep. 2004 (M)

3rd edition: Aug. 2013 (F)

Loading...

Loading...