WWW.BALTIMOREAIRCOIL.COM

38

SERIES 3000 COOLING TOWER

New Field Connections for

TriArmor

8

Thefollowingareinstallationinstructionsforaddingneweldconnections(Equalizer/

Bypass/Outlet)onacoldwaterbasinwiththeTriArmor

®

CorrosionProtectionSystem.

1. UsetheBACtemplateprovidedwiththeaccessorytolayoutandmarktheholepattern

ontheexteriorofthecoldwaterbasin.

2. Drillapilotholefromtheoutsideofthecoldwaterbasintotheinsideofthecold

waterbasin.

3. Ontheinsideofthecoldwaterbasin:

a. Forconnections3”orless,scoretheTriArmor

®

CorrosionProtectionSystemwitha

holesawasshowninFigure 12.

b. Forconnections3”orgreater,proceedtostep4and4b.

Supplies Provided by BAC Recommended Supplies Provided by Others

Template for the connection with bolt holes Stainless steel threaded shoulder bolts

Type 304 stainless steel backing ring with gasket 150 lb flange, weld any piping to the flange prior to installation

Vulkem

®

caulk Gasket for the outside of the cold water basin

Table 6. Supplies for Installing Field Connections

Figure 12. Scored TriArmor

®

Corrosion Protection System

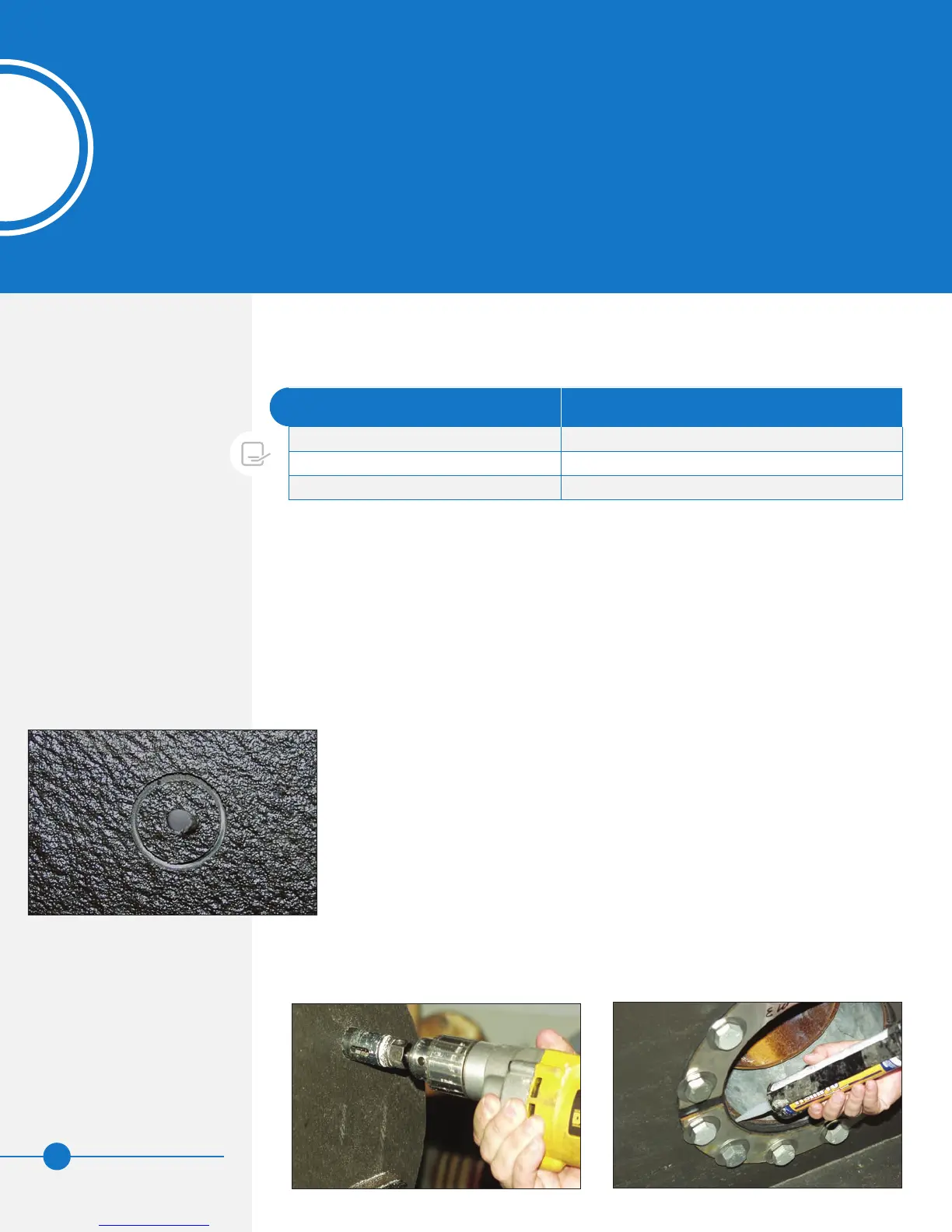

Figure 13. Removal Material

NOTE: BAC recommends adding a

flange connection for field installed

equalizers, bypass and outlet

connections. Please order the

recommended supplies listed in

Table 6 prior to unit shutdown.

Figure 14. Caulk Exposed Galvanized Steel

4. Cuttheholefromtheoutsideofthecoldwaterbasin.

a. Useaholesaworastepdrillbitforsmallerconnections3”orlessas

showninFigure 13.

b. UseareciprocatingsaworaSawzall

®

forlargerconnections3”orgreater.

5. PositiontheBACsuppliedstainlesssteelbackingringgaskettotheinside

ofthecoldwaterbasin.

6. Positiontheangetotheoutsideofthecoldwaterbasin.

7. Bolttheangeandthestainlesssteelbackingplatetogetherusingstainless

steelbolts.

8. Sealanyexposedgalvanizedsteeloftheconnectioninsidethecoldwater

basinwithVulkem

®

caulkasshowninFigure 14.

Loading...

Loading...