| 26 |

EN

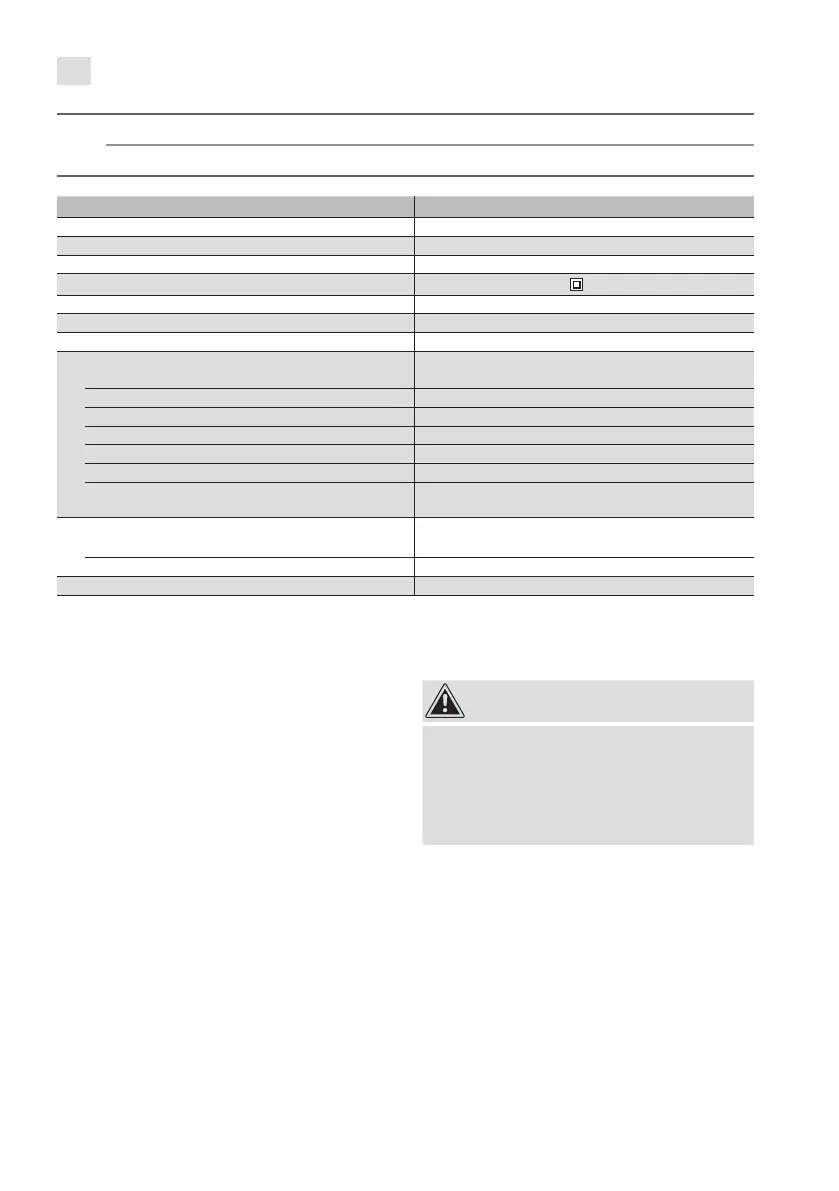

3 Technical Characteristics

3.1 Technical specifications

Wall chaser type BMF 501

Manufacturer Maschinenfabrik OTTO BAIER GmbH

Operating voltage (V / Hz) ~230 / 50 / 60

Power consumption (watt) 1400

Protection class

/ II

Speed (min

-1

) 2150

Cutting width (mm) 13 – 30

Cutting depth (mm) 23 – 38

Weight (kg)

Machine

1)

6.5

Euro cutter 20 0.15

Euro cutter 25 0.15

Cutter 4 0.15

Cutter 318 0.15

Cutter 67 0.20

Cutter 67 for sand-lime

(calcium silicate) brick

0.20

Sound measurement

2)

K = 3 dB

L

pA

(sound pressure) dB (A) 94

L

WA

(sound power) dB (A) 103

Vibration measurement:

3)

K = 1.5 m/s

2

6.4

1)

Weight without insert tool and connection cable.

2)

Measured values for noise determined according to EN 60745. Wear hearing protection!

3)

Total vibration values (vector sum in three directions) determined according to EN 60745

The vibration emission values given in this instruc-

tion manual have been measured according to a

method of measurement standardised in EN 60745

and can be used for comparison between electric

tools. They are also suitable for a preliminary esti-

mate of the vibratory stresses.

The vibration emission values given represent the

main applications of the electric tool. If the electr

ic

tool is used for other applications, with different in-

sert tools or are used insufficiently serviced, this

can increase the vibratory stresses over the whole

work period. For a precise estimate of the vibra-

tion emission values, the times during which the tool

is switched off or is running but not actually in use

should also be taken into account. This can reduce

the vibration stresses over the whole work period

significantly.

WARNING

Health risk due to vibrations.

Additional safety measures should be taken to

protect the user, e.g. wearing anti-vibration pro-

tective gloves, correct maintenance of electric

tools and insert tools, keeping the hands warm

and good organisation of the work sequences.

Loading...

Loading...