Grand GDS, Power GDS

Grand ES, Power ES, Grand DS, Power DS

Grand GDS, Power GDS

Grand ES, Power ES, Grand DS, Power DS

Grand GDS, Power GDS

Grand ES, Power ES, Grand DS, Power DS

Grand GDS, Power GDS

Grand ES, Power ES, Grand DS, Power DS

Grand GDS, Power GDS

Grand ES, Power ES, Grand DS, Power DS

Grand GDS, Power GDS

Grand ES, Power ES, Grand DS, Power DS

Grand GDS, Power GDS

Grand ES, Power ES, Grand DS, Power DS

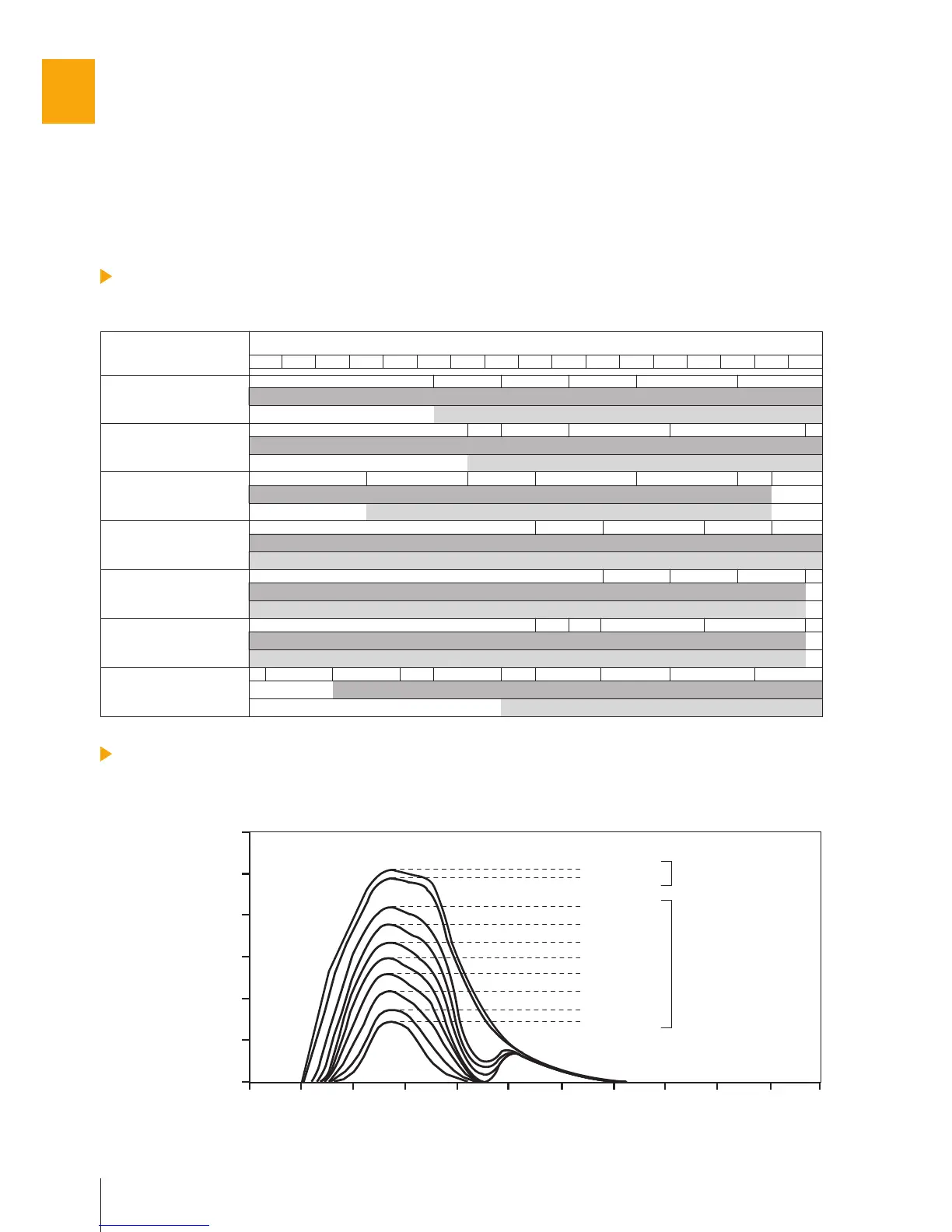

WELDING

PROCESS

MMA

CURRENT IN AMPERES

MAG

TIG

MIG heavy metals

MIG light metals

Stainless, AI

Plasma cutting

Micro plasma welding

6 10 15 30 40 60 70 100 125 150 175 200 225 250 300 350 400

9 10 11 12 138

9 10 11 128

9 10 11 12 138 14

9 10 11 12 13

10 11 12 13

9 10 11 12 13

4 5 6 7 8 9 10 11 12 13

Opening time delay adjustment: The opening time delay can be adjusted from 0.1 to 1.0 sec-

onds. It is recommended to use a shorter delay with spot welding applications and a longer delay

with applications using higher currents and longer welding intervals. Longer delay can also be

used for low current TIG welding in order to prevent the filter opening when the light path to the

sensors is temporarily obstructed by a hand, torch, etc.

Function welding/grinding

(models Power GDS, Grand GDS only): For these filters, two modes

of operation can be selected: welding or grinding. By selecting the position »Grind«, the filter

switches off and it will not be triggered by the sparks generated during grinding. Before restarting

welding work, the knob should be set back to the »Weld« position.

RECOMMENDED SHADE LEVELS FOR VARIOUS WELDING APPLICA-

TIONS / EN 379 /

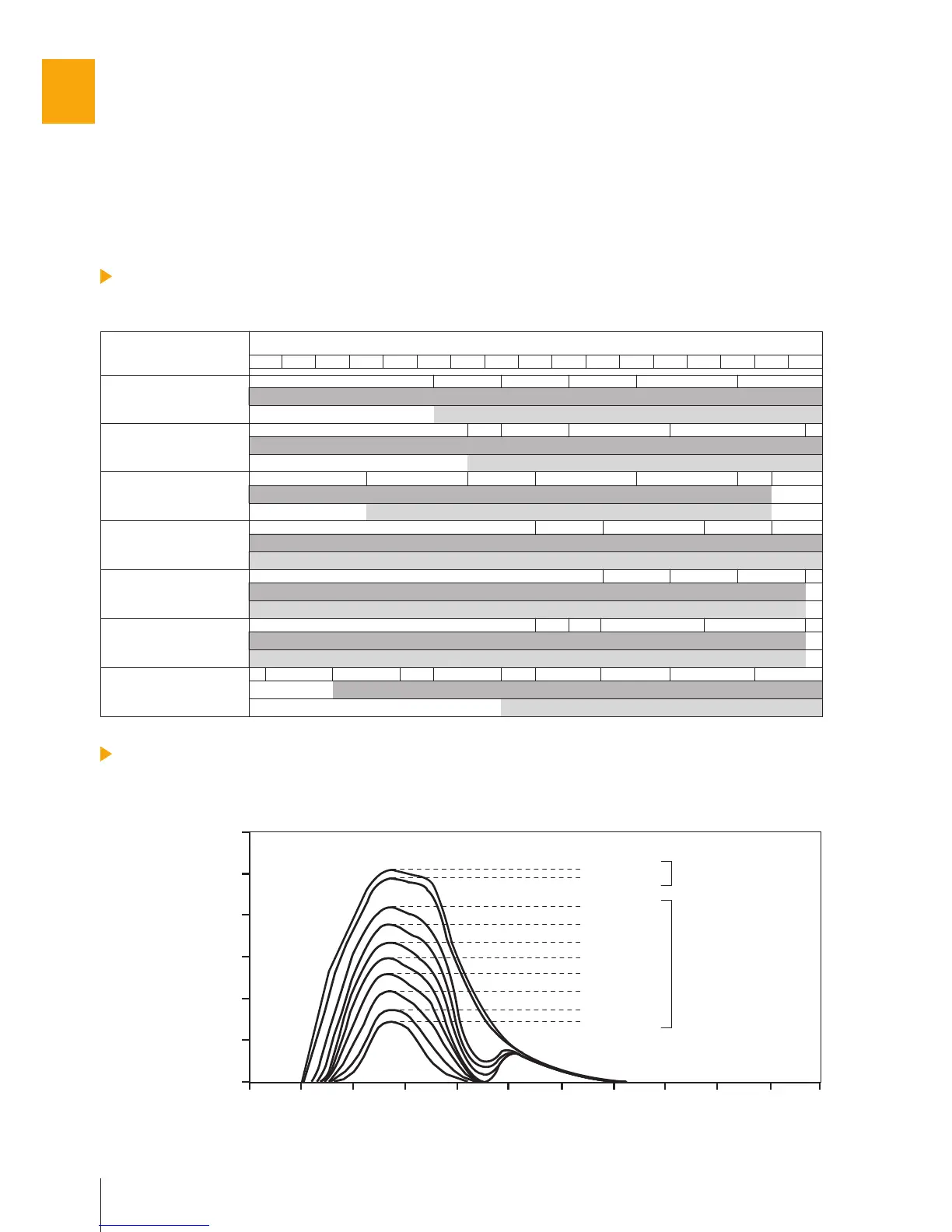

LIGHT TRANSMISSION CURVE

0,0001

0,001

0,01

0,1

1

10

100

T[%]

300 400 500 600 700 800 900 1000 1100 1200 1300 1400

λ[nm]

Shade 3

Shade 4

Shade 6

Shade 7

Shade 8

Shade 9

Shade 10

Shade 11

Shade 12

Shade 13

LIGHT STATE

Transmission

Wavelength

DARK STATE

14

GB

Loading...

Loading...