13-11

®

LUBRICATION & FLUID SPECIFICATIONS

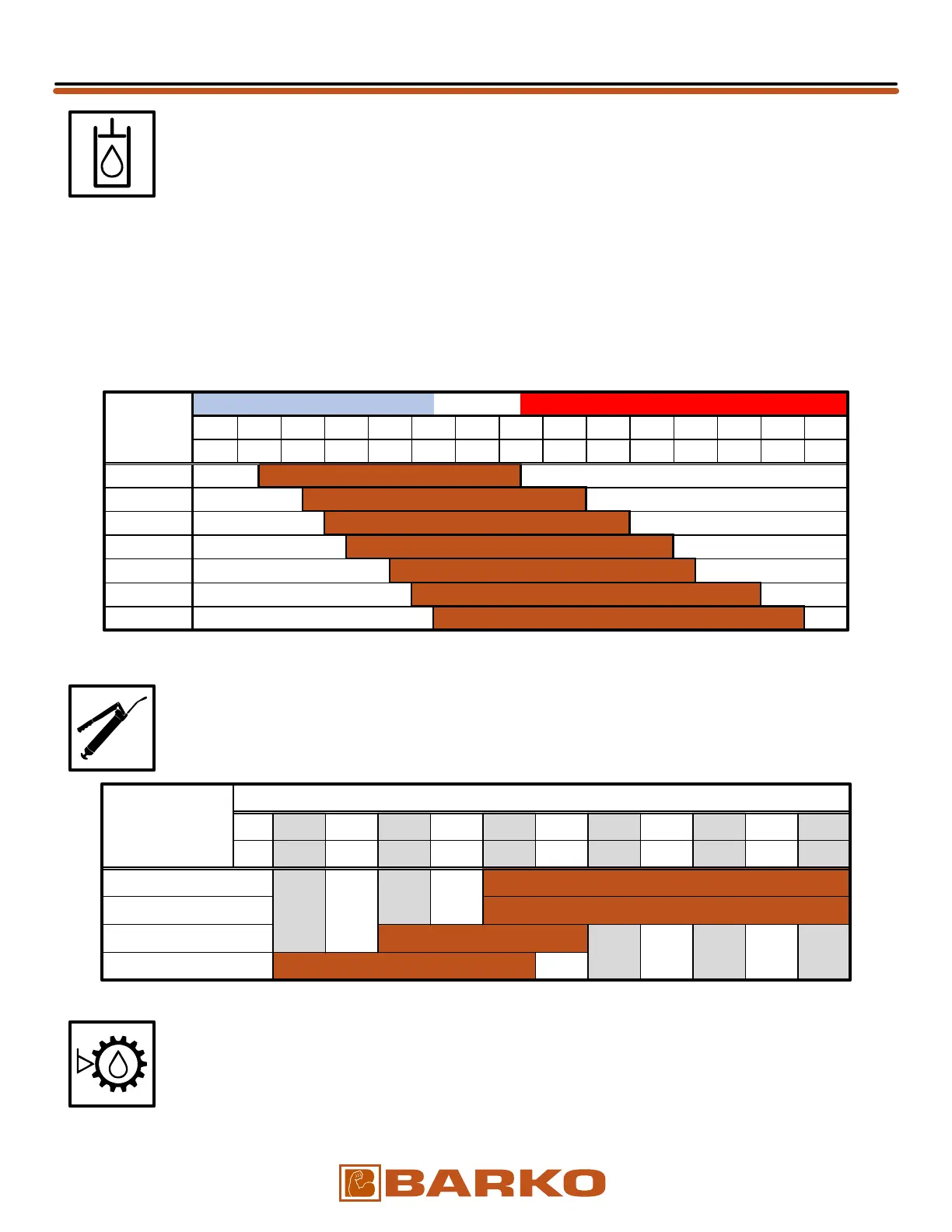

(°F)

10

15

22

32

46

68

100

-4-22

-27° to 90°F (-33° to 32°C)

-10° to 111°F (-23° to 44°C)

5° to 131°F (-15° to 55°C)

39° to 183°F (4° to 84°C)

50° to 201°F (10° to 94°C)

176 194 212

104 122 140 158

ISO

VISCOSITY

GRADE

LOWEST AMBIENT TEMPERATURE

TO

MAXIMUM OPERATING TEMPERATURE

28° to 163°F (-2° to 73°C)

18° to 147°F (-8° to 64°C)

8668503214

(°F) -58 -40 -22 -4 14 32 50 68 86 104 122

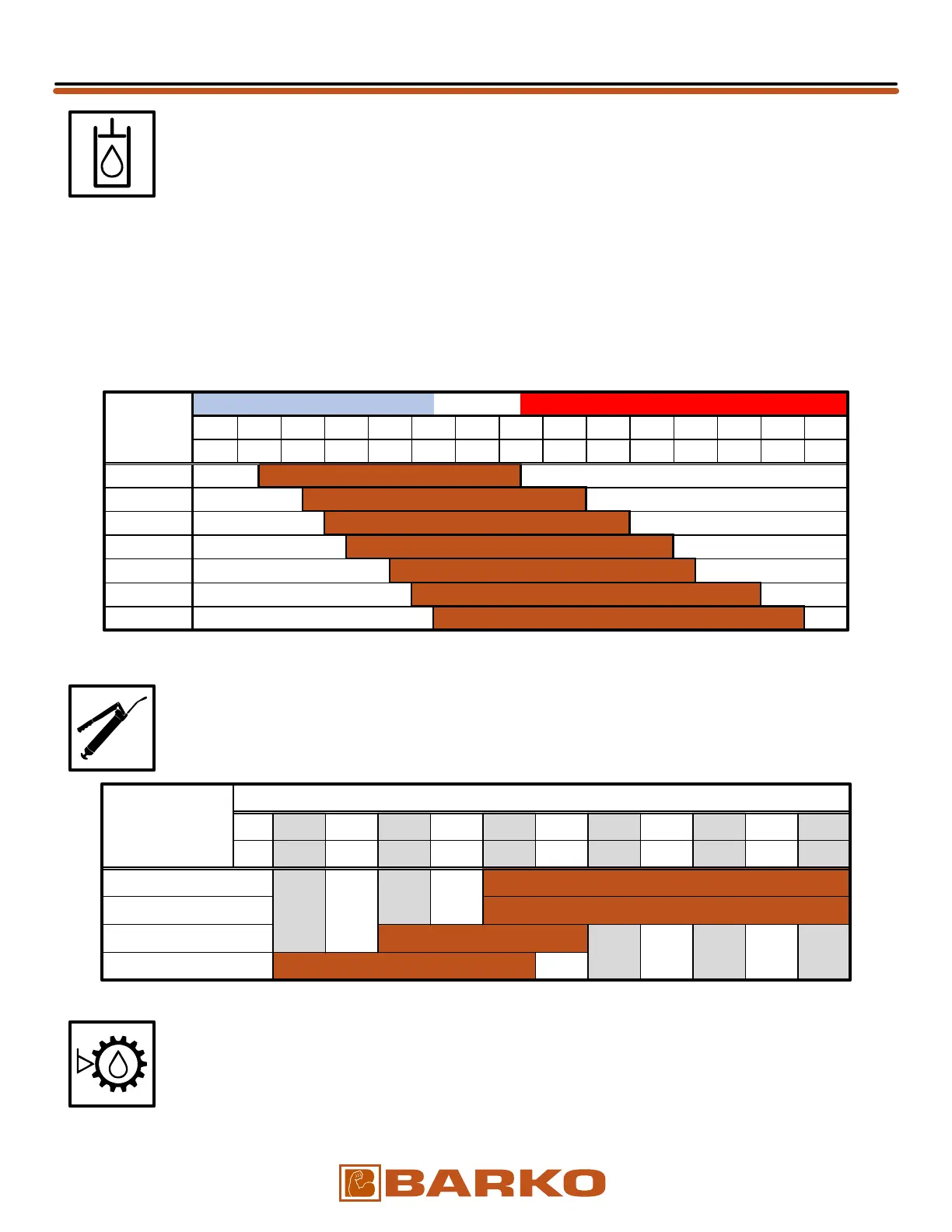

(°C) -50 -40 -30 -20 -10 0 10 20 30 40 50

GREASE TYPE

-20°F (-30° C) to 32°F (0°C)

HYDRAULIC OIL

The following lists some features to look for in an oil. The hydraulic oil for the machine should

feature:

Ÿ Rust resistant additives to prevent rust formation from moisture condensation.

Ÿ Anti-foaming agents to break up air bubbles and prevent "foaming" that may cause

sluggish and erratic operation.

Ÿ High stability to resist oxidation and prevent varnish formation and deposits that foul

systems.

Ÿ Anti-wear properties to prevent scuffing and excessive wear at high speeds and high

pressures.

Ÿ Good viscosity index for easy flow at low temperatures without thinning out at high temp's

after hours of use.

For operation in different temperatures, refer to Table 1 for selection of hydraulic oil:

GREASE

Use Grease Types listed in Table 2 below for expected temperature ranges.

GEAR OIL

See system chapters in this manual for gear oil specifications for specific machine

components.

Table 1

Table 2

07/26/2018

Updated

OPERATOR’S

Loading...

Loading...