13-26

®

LOADER MOUNTING INSTRUCTIONS

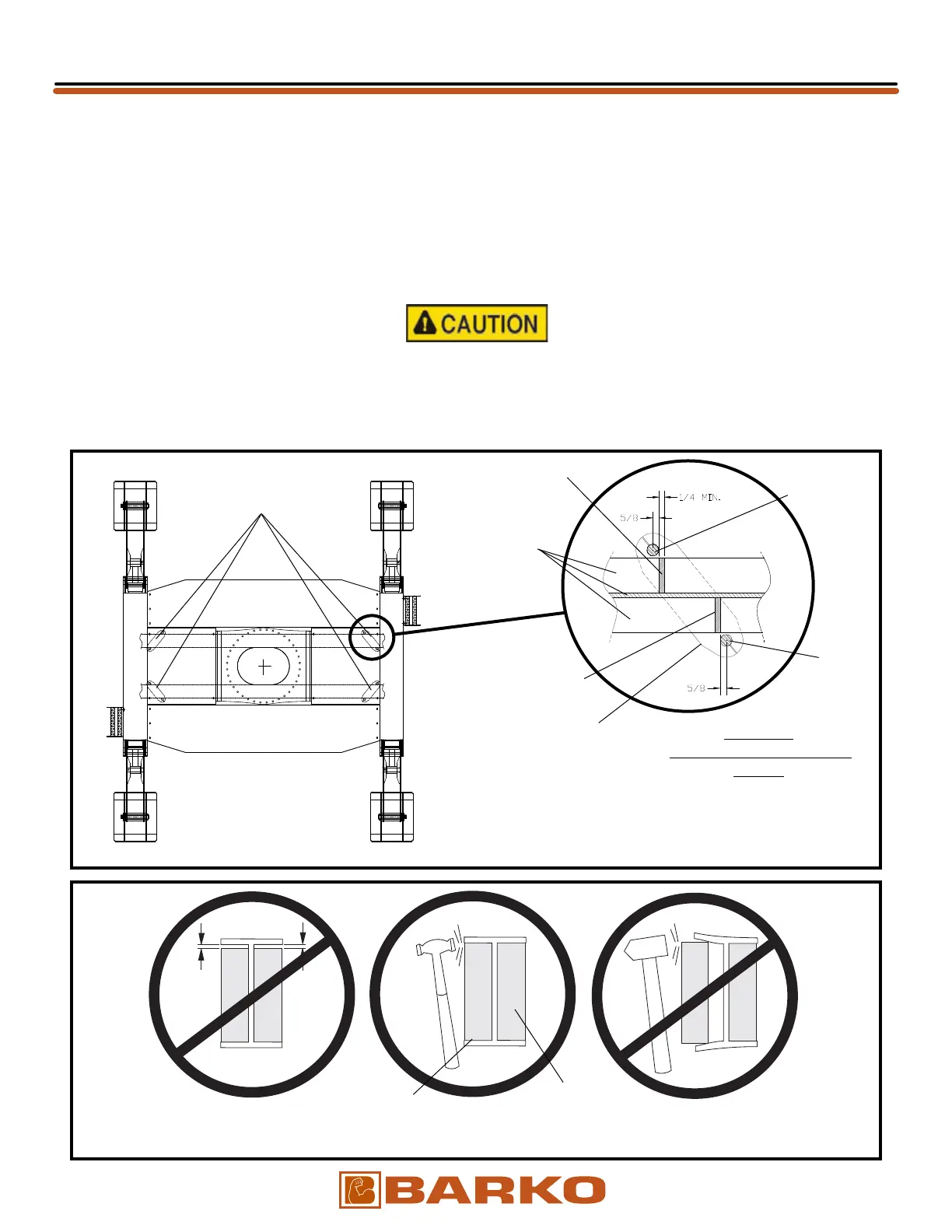

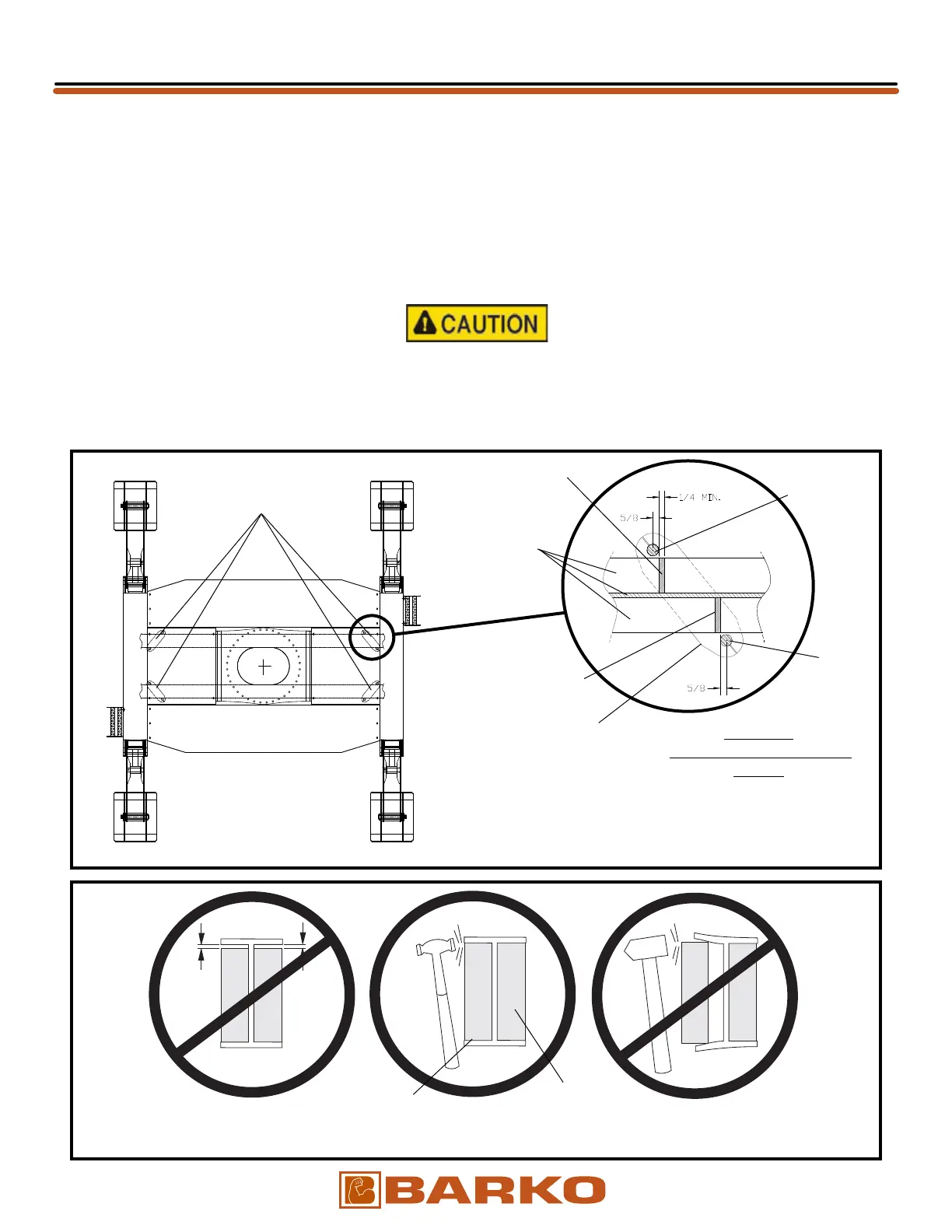

Do not cut spacer blocks too short, which will cause a loose fit, or too long which will cause frame to

spread. See Figure 2.

Use these recommended procedures for mounting the loader to a truck or trailer frame. Truck/trailer frame

is usually made of channel or I-beam. The following instructions show mostly I-beam, however the

principles for mounting to channel are generally the same, unless noted.

1. Using suitable lifting equipment, place loader on truck/trailer frame over axles, leaving enough room for

tailswing of machine plus two ft.

2. Install two spacer blocks at each of the four mounting points (See Figure 1 for offset mounting locations).

Spacer blocks must be slightly longer than the opening between I-beam edges so that they fit snug. See

Figure 2. Spacer blocks must be a minimum of 1/4" thick. DO NOT WELD SPACER BLOCKS TO

TRUCK/TRAILER FRAME!

NOTE: To prevent distortion of truck/trailer frame and ensure solid base for the loader, align spacer blocks

with edge truck/trailer frame but offset them from mounting studs as shown in Detail A in Figure 1.

Figure 1

Mounting Points

(there are four) on

subframe of machine.

Truck/Trailer

Frame

Spacer Block

Stud

Spacer Block

Clamping Plate

Stud

DETAIL A

Offset locations of Spacer

Blocks.

Figure 2

NO

OK

NO

Spacer Block

(offset one on each side

truck/trailer frame)

Truck/Trailer

Frame

07/26/2018

Updated

OPERATOR’S

Loading...

Loading...