825TKL OWNER’S MANUAL 10/17/22 Page 11 of 22

HYDRAULIC HOSE REPLACEMENT

• Make sure Track Loader is turned off and cooled down.

• Ensure the Track Loader is on a level and stable surface/ground.

• Identify the size of the tool needed for hose removal.

• Have shop rags/towels handy to absorb any fluid in the line.

• Make sure your replacement hose is the correct one.

• Once hose is replaced, make sure the fittings are tightened back up.

• Start machine and run all functions.

• Inspect hose(s) for leaks.

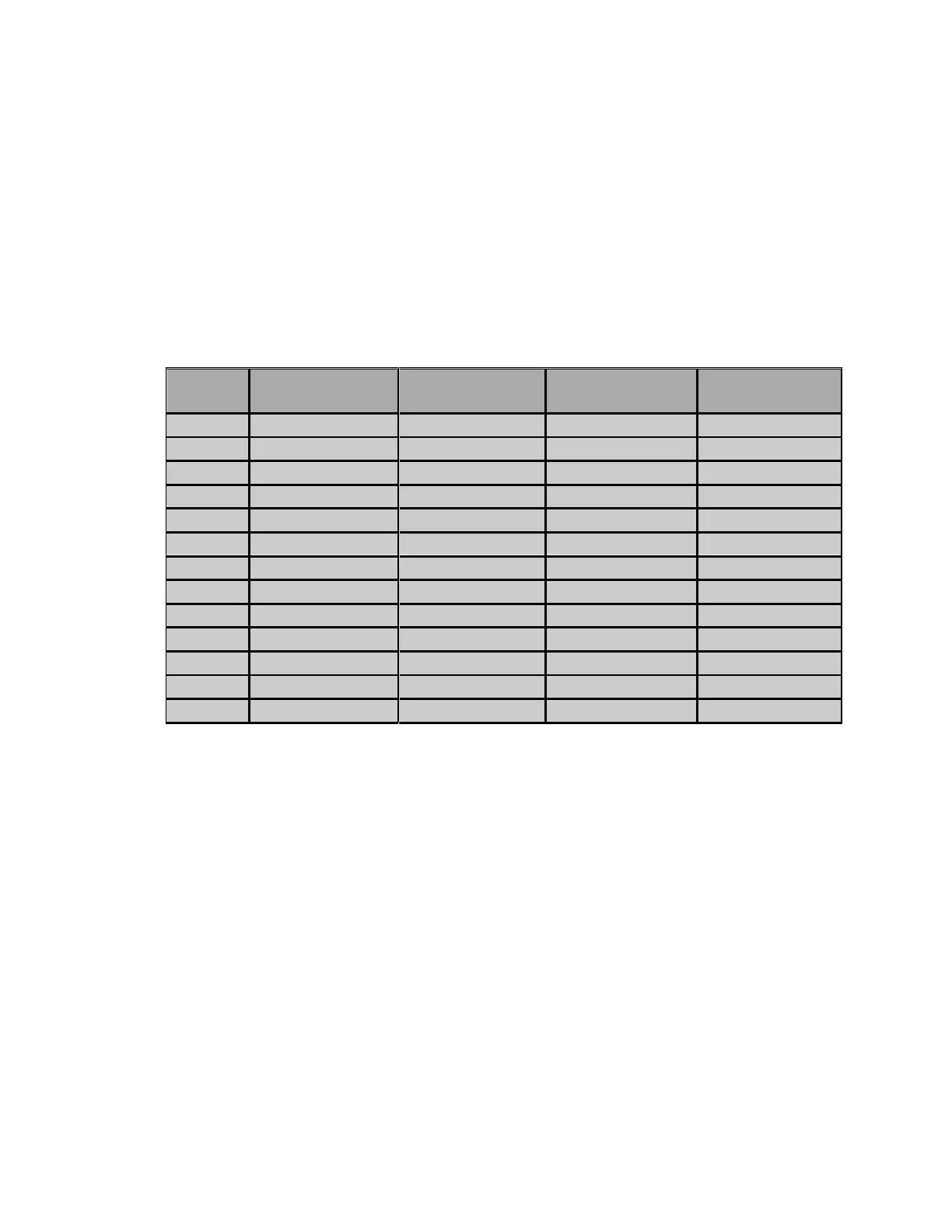

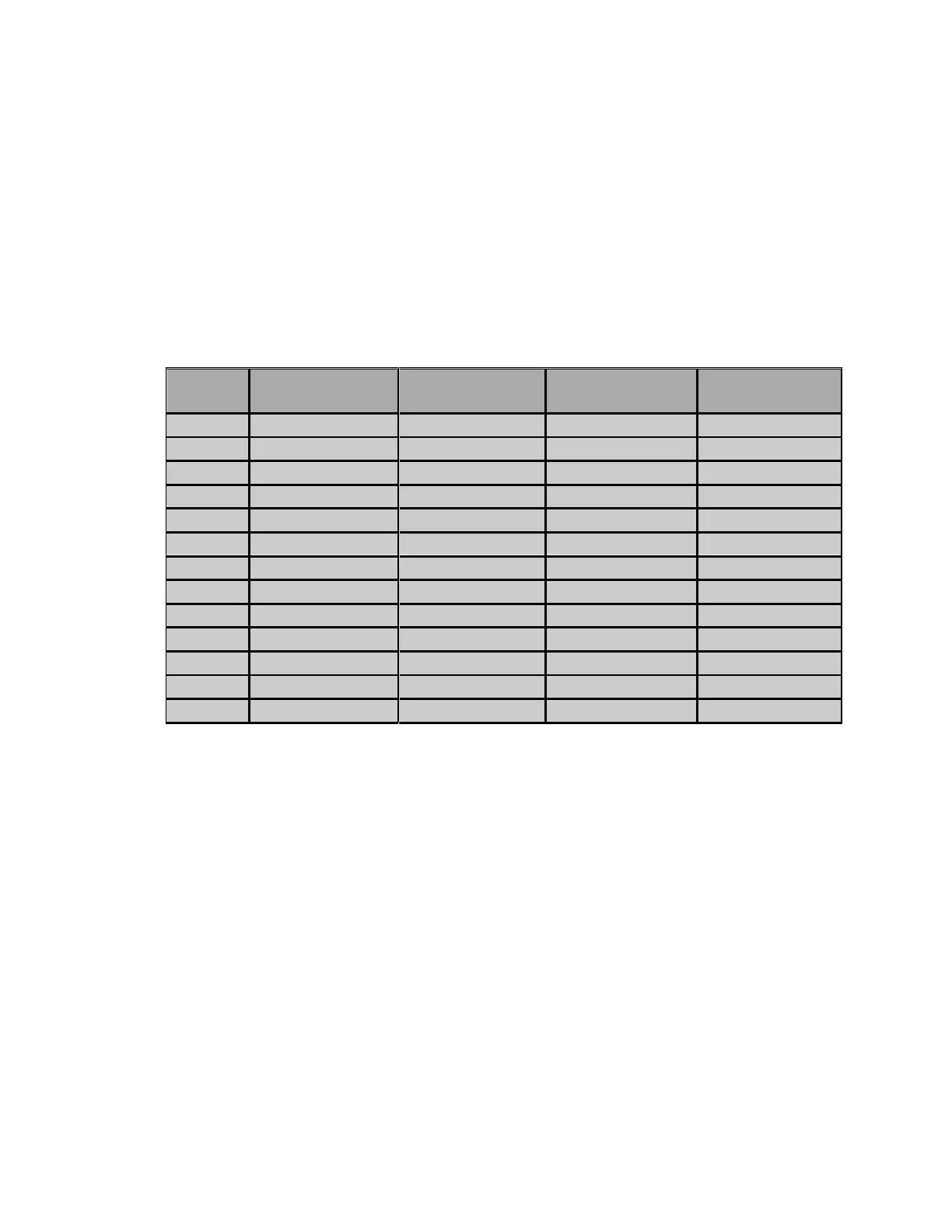

• Tighten fittings to spec as illustrated below.

• Make sure hydraulic fluid is filled to the top of the sight glass. (If low see page 3)

CHANGING THE HYDRAULIC FLUID

• Lift machine high enough to place a container large enough to hold at least 15 gallons.

• Remove the drain plug using a 5/16” hex key wrench and allow to drain.

• Replace drain plug.

• Remove the fill plug using a 9/16” hex key wrench.

• Fill to the top of the sight glass using a suitable ISO 68 hydraulic fluid.

• Replace fill plug.

• Dispose of the used fluid according to your local laws and regulations.

Loading...

Loading...