24 • Important: Always read and follow operating instructions.

Maintain Bolt Torque

at 240 ft. lbs.

Grease Fittings

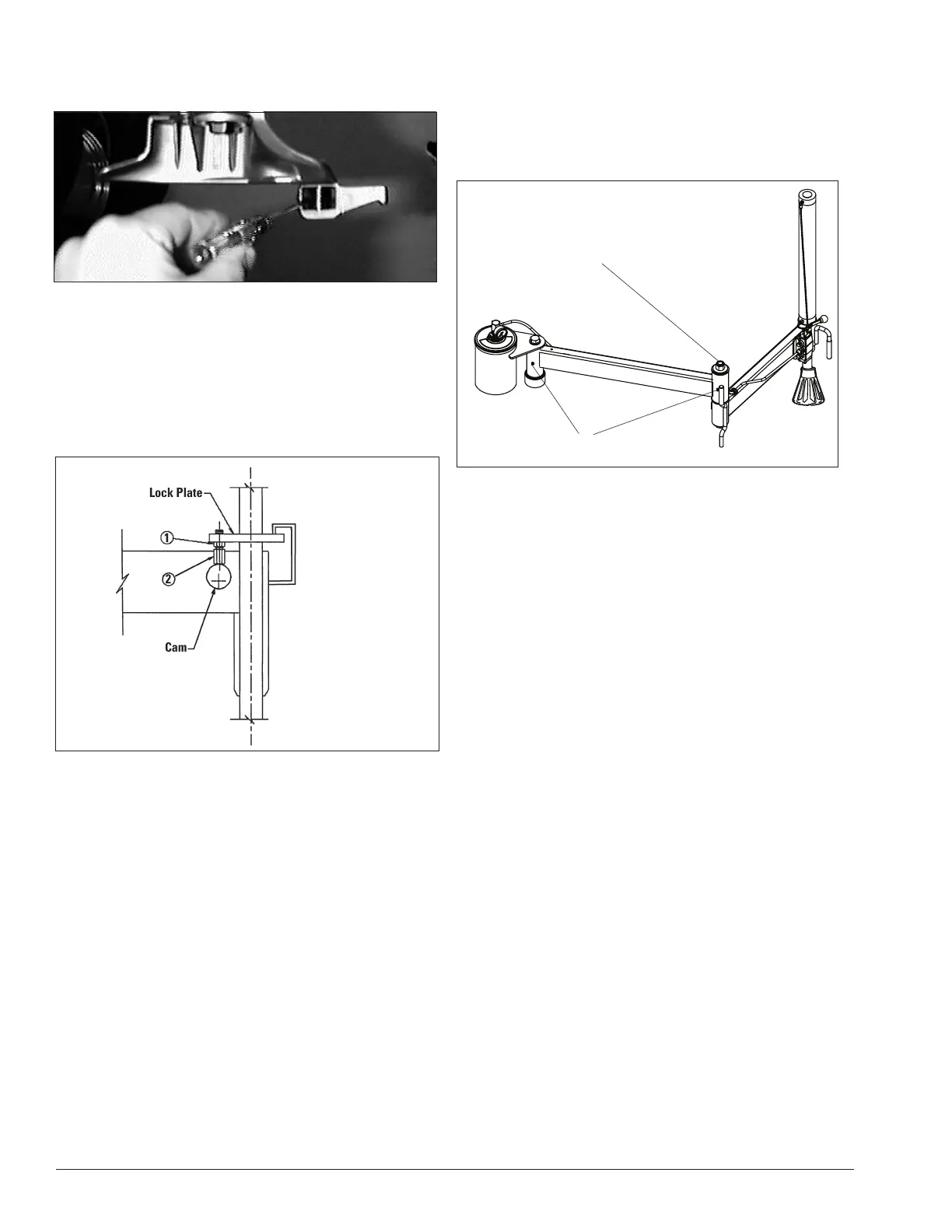

Mount/Demount Tool Cleaning

Clean dirt and debris from the Duckhead

®

mount/

demount tool roller with a small screwdriver or pick.

Figure 34 – Clean Duckhead

®

Mount/demount Tool Using

Small Screwdriver

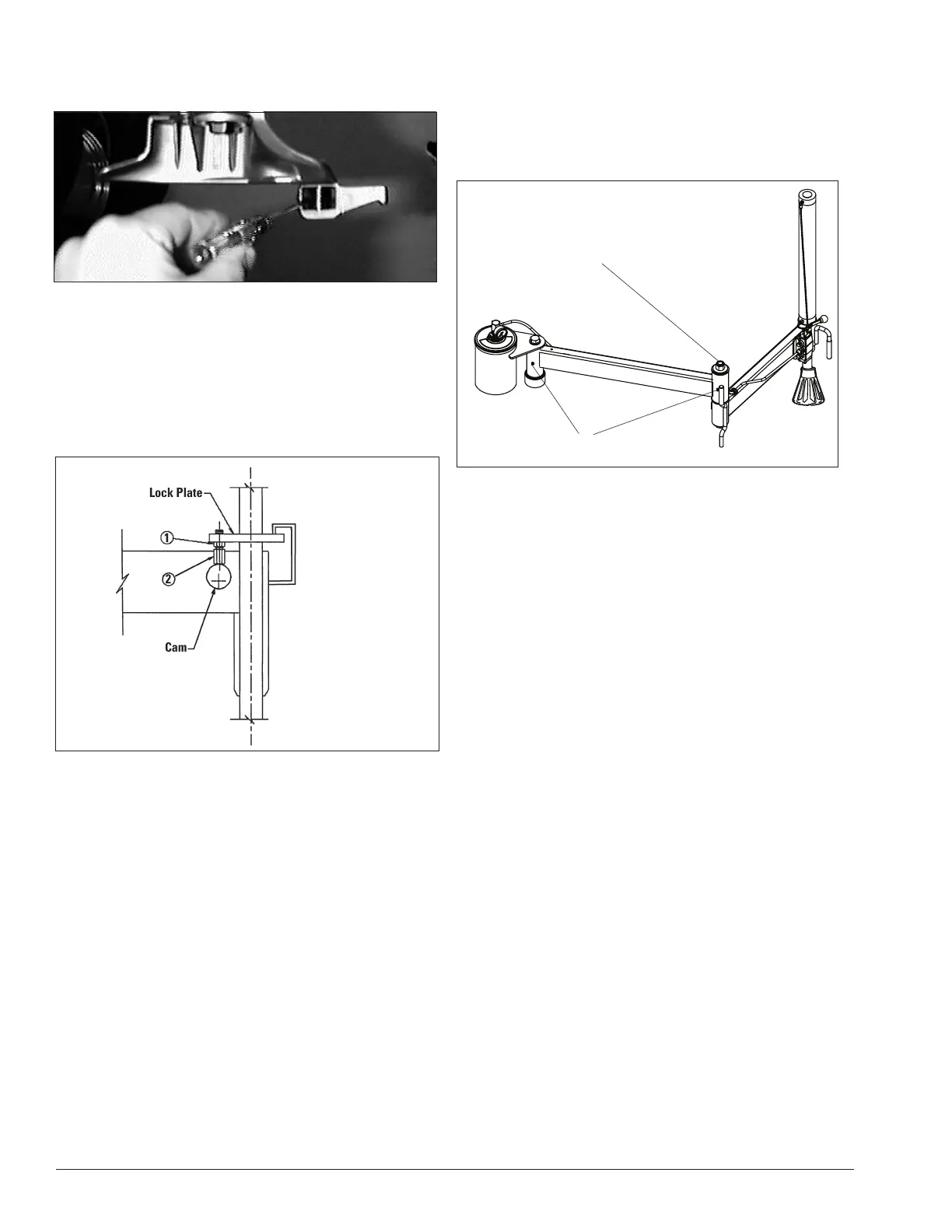

Mount/Demount Tool Adjustment

To Adjust Lock Tightness

With lock handle unlocked, loosen jam nut (ref. 1) and

adjust pin (ref. 2) until a slight firmness is obtained,

then tighten jam nut and check. Also recheck tool lift

at this time.

Figure 35 - Mount/Demount Tool Adjustment

Robo-Assist

®

Helper Arm Maintenance

Grease the Robo-Assist

®

Helper Arm to maintain

smooth rotation. Grease fittings are installed at the

pivot joints.

Check bolt torque periodically at pivot joints. Proper

Torque is 240 ft. lb.

Figure 36 – Grease Robo-Assist

®

Joints and Torque bolts

Loading...

Loading...