Table 3. System Start-Up

1. Perform the preliminary set-up.

2. Start prime mover and bring up to rated

speed.

If the voltage does not build up:

a. Flash Field

b. Remove power for 1 minute to allow

the overexcitation circuit to reset.

3. Slowly adjust

VOLT

adjustment or external

voltage adjust rheostat until voltage reaches

nominal.

If the voltage does not build up to the rated

value, check the generator output for a

shorted or excessive load.

4. Apply and remove load to check stability.

If the generator response is too slow or is

hunting (oscillating):

a. Check generator output for shorted

or excessive load. Adjust

STB

with

no load applied.

b. Check stability of governor system.

5. Check regulation under normal operating

conditions.

If the regulation is poor:

a. Check that the prime mover is up to

rated speed.

b. Check that the voltmeter is

connected at the same point as the

regulator sensing.

c. Use an average sensing voltmeter

(not an RMS sensing voltmeter).

6. Reduce generator frequency. Generator

output should decrease from this point.

If the generator output voltage does not

decrease at desired frequency:

a. Check that all the wiring is in

accordance with the connection

diagrams provided in these

instructions.

b. Adjust

FREQ

control.

OPERATIONAL TEST

This test is designed to test all eight models of

the AVC63-12 and AVC125-10. See Table 4 for

appropriate testing voltages and frequencies.

To operationally test any AVC63-12 or AVC125-

10, perform the following steps.

a. Connect the voltage regulator as shown by

Figure 9 and apply appropriate voltages.

b. Adjust the front panel

VLT ADJ

control fully

counterclockwise (CCW).

RESULT:

Observe that the lamp is OFF.

c. Adjust the front panel

VLT ADJ

control

clockwise (CW).

RESULT

: Observe that the lamp is now ON.

d. Adjust the front panel

VLT ADJ

control until

the lamp just goes out.

Regulator operation is satisfactory if the above

results are obtained. Stability, however, must be

tested with the generator and regulator in

operation.

MAINTENANCE

Preventive Maintenance

A periodic inspection should be made of the

voltage regulator to ensure that it is clean and

free from accumulations of dust and moisture.

Be sure that all connections are clean and tight.

Troubleshooting

In case of failure/defective operation of the unit,

simplifying the system by eliminating com-

ponents, such as remote adjust potentiometers

and other non-essential items can be helpful in

the troubleshooting process.

Table 4. Testing Parameters

Input

Sensing

Model Power Vac Freq.

AVC63-12A1 120 120 50/60

AVC63-12A2 120 120 400

AVC63-12B1 120 240 50/60

AVC63-12B2 120 240 400

AVC125-10A1 240 120 50/60

AVC125-10A2 240 120 400

AVC125-10B1 240 240 50/60

AVC125-10B2 240 240 400

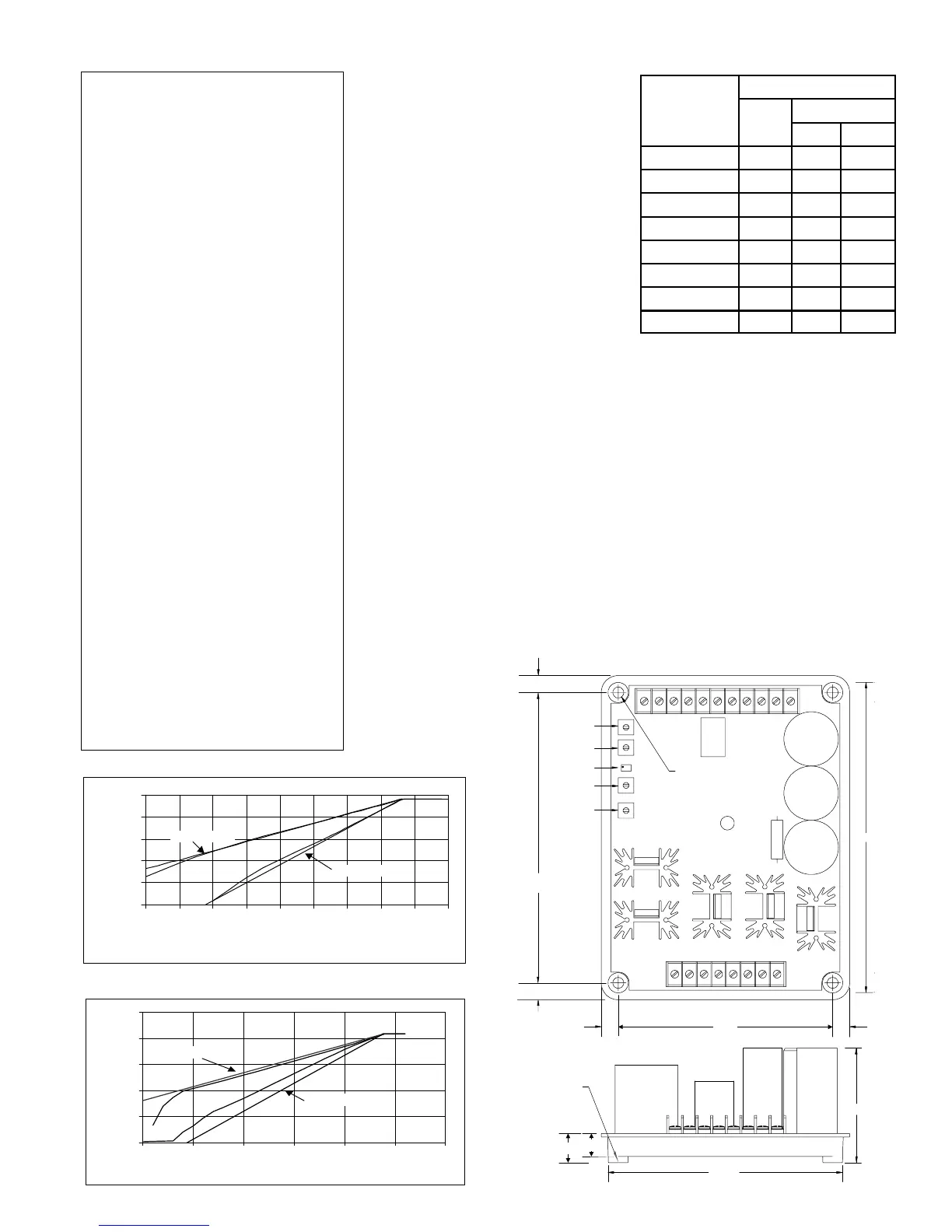

0

50

100

150

200

250

20 25 30 35 40 45 50 55 60 65

Frequency In Hertz

Terminal Voltag

Ideal 1 PU/Hz

Ideal 2 PU/Hz

Figure 1. 60 Hertz Frequency Compensation

0

50

100

150

200

250

150 200 250 300 350 400 450

Fre

uenc

in Hertz

Terminal Voltage in Volts

Ideal 2 PU/Hz

Ideal 1 PU/Hz

Figure 2. 400 Hertz Frequency Compensation

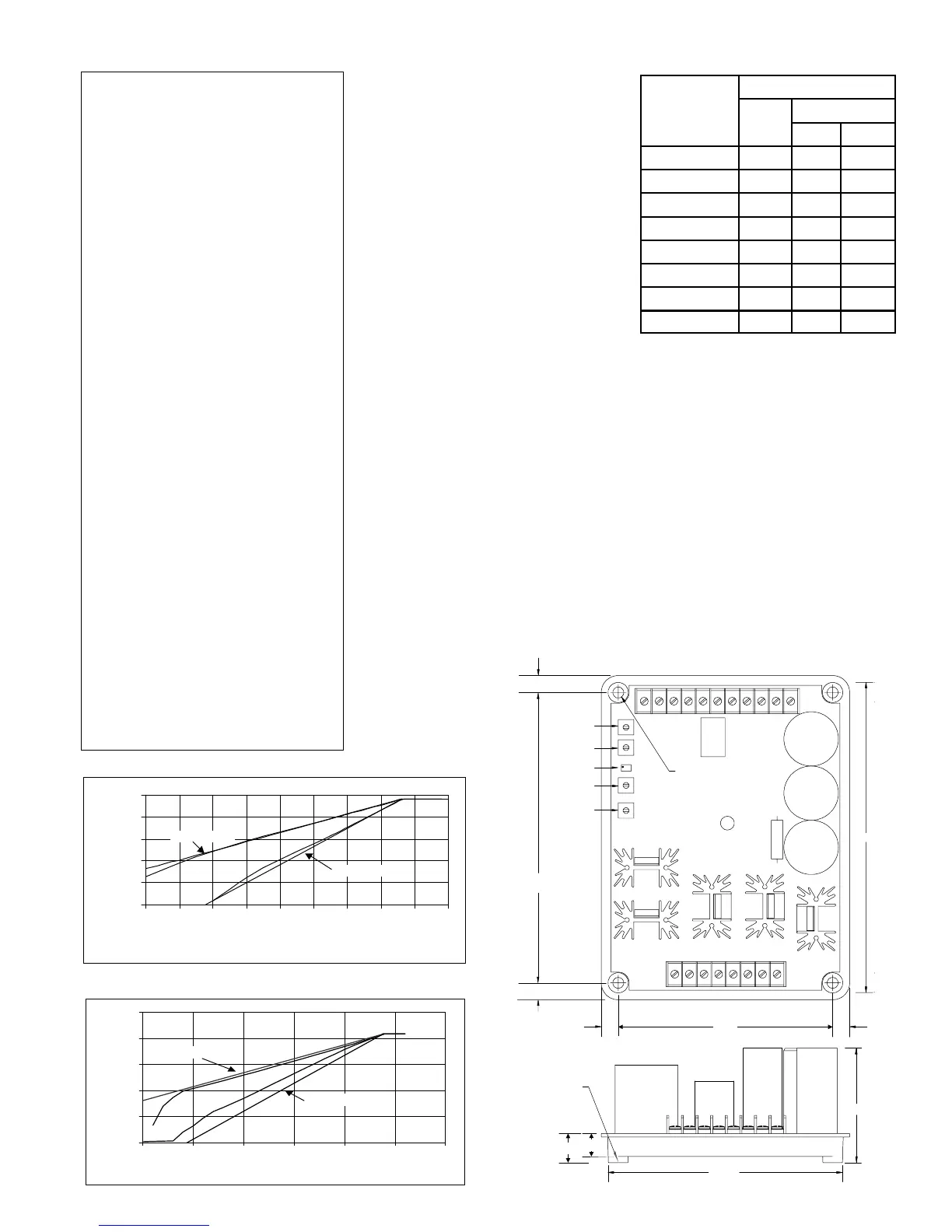

5.500

0.593

.281 DIA. HOLE

(4 PL)

6.01

D2590-30.vsd

06-20-01

0.438

STB

VLT ADJ

UF KNEE

FAC CAL

DRP

23455a66a789

F2F1302826242220

0.438

7.500

2.96

0.438

0.438

CH

GND

.750

.51 DIA.

(4 PL)

8.01

Figure 5. Outline Drawing

Loading...

Loading...