Crankaxle dis- and reassembly

Chain:

Remove pedal transmission chain by loosening the

connector.

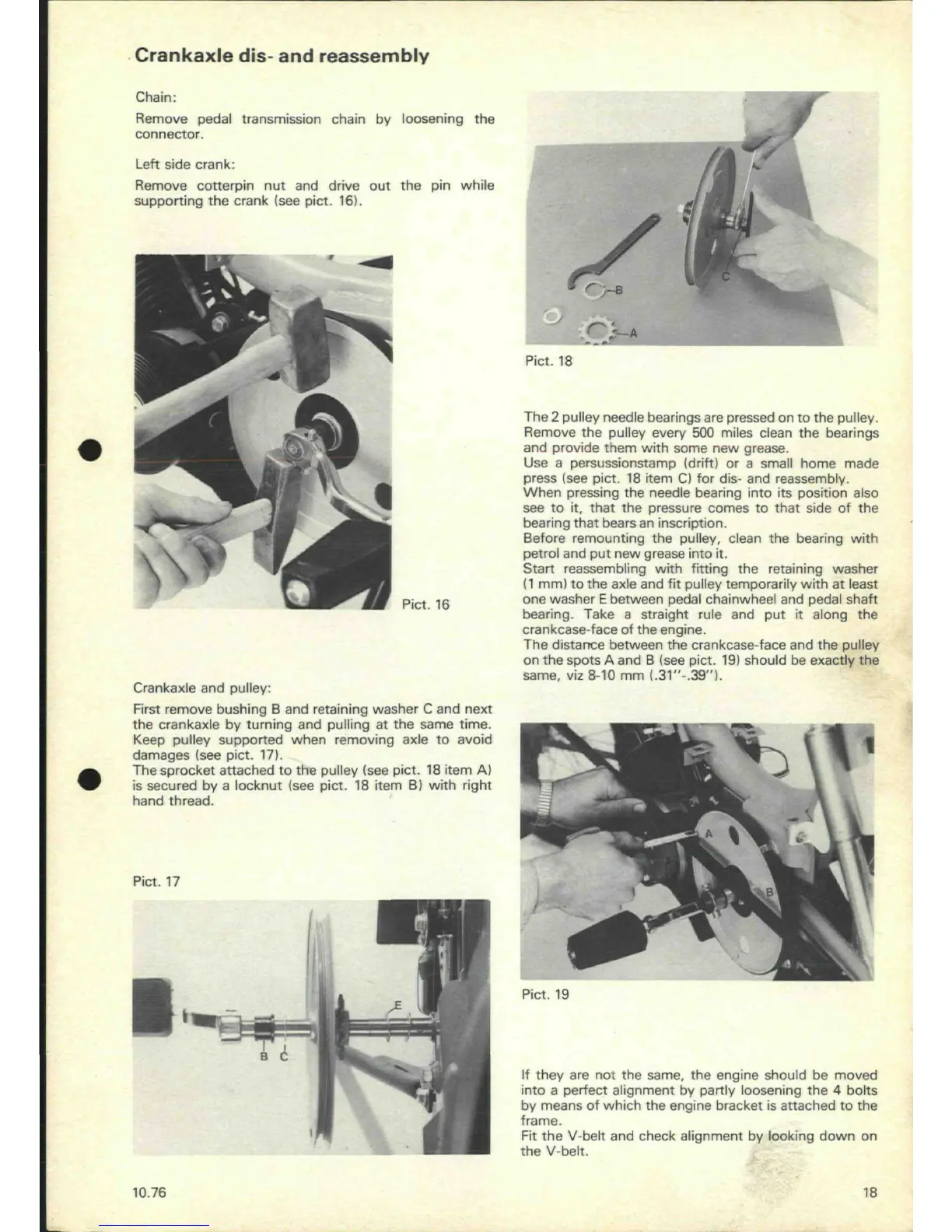

Left side crank:

Remove cotterpin nut and drive out the pin while

supporting the crank (see pict. 16).

Pict. 16

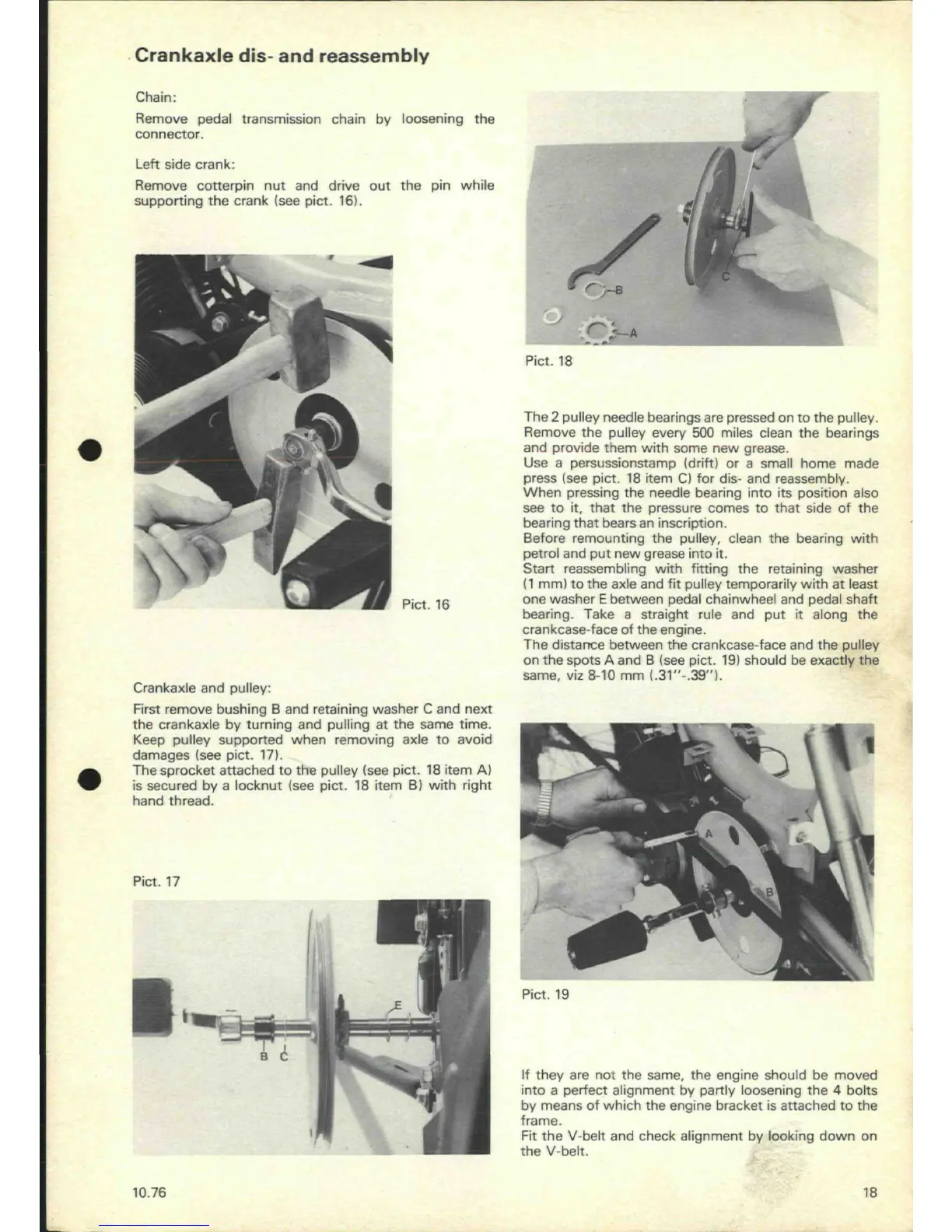

Crankaxle and pulley:

First remove bushing B and retaining washer C and next

the crankaxle by turning and pulling at the same time.

Keep pulley supported when removing axle to avoid

damages (see pict. 17).

The sprocket attached to the pulley (see pict. 18 item A)

is secured by a locknut (see pict. 18 item B) with right

hand thread.

Pict. 17

Pict. 18

The 2 pulley needle bearings are pressed on to the pulley.

Remove the pulley every 500 miles clean the bearings

and provide them with some new grease.

Use a persussionstamp (drift) or a small home made

press (see pict. 18 item C) for dis- and reassembly.

When pressing the needle bearing into its position also

see to it, that the pressure comes to that side of the

bearing that bears an inscription.

Before remounting the pulley, clean the bearing with

petrol and put new grease into it.

Start reassembling with fitting the retaining washer

(1 mm) to the axle and fit pulley temporarily with at least

one washer E between pedal chainwheel and pedal shaft

bearing.

Take a straight rule and put it along the

crankcase-face of the engine.

The distance between the crankcase-face and the pulley

on the spots A and B (see pict. 19) should be exactly the

same,

viz 8-10 mm

(.31"-.39").

^

Pict. 19

If they are not the same, the engine should be moved

into a perfect alignment by partly loosening the 4 bolts

by means of which the engine bracket is attached to the

frame.

Fit the

V-belt

and check alignment by looking down on

the V-belt.

10.76

18

Loading...

Loading...