26

27

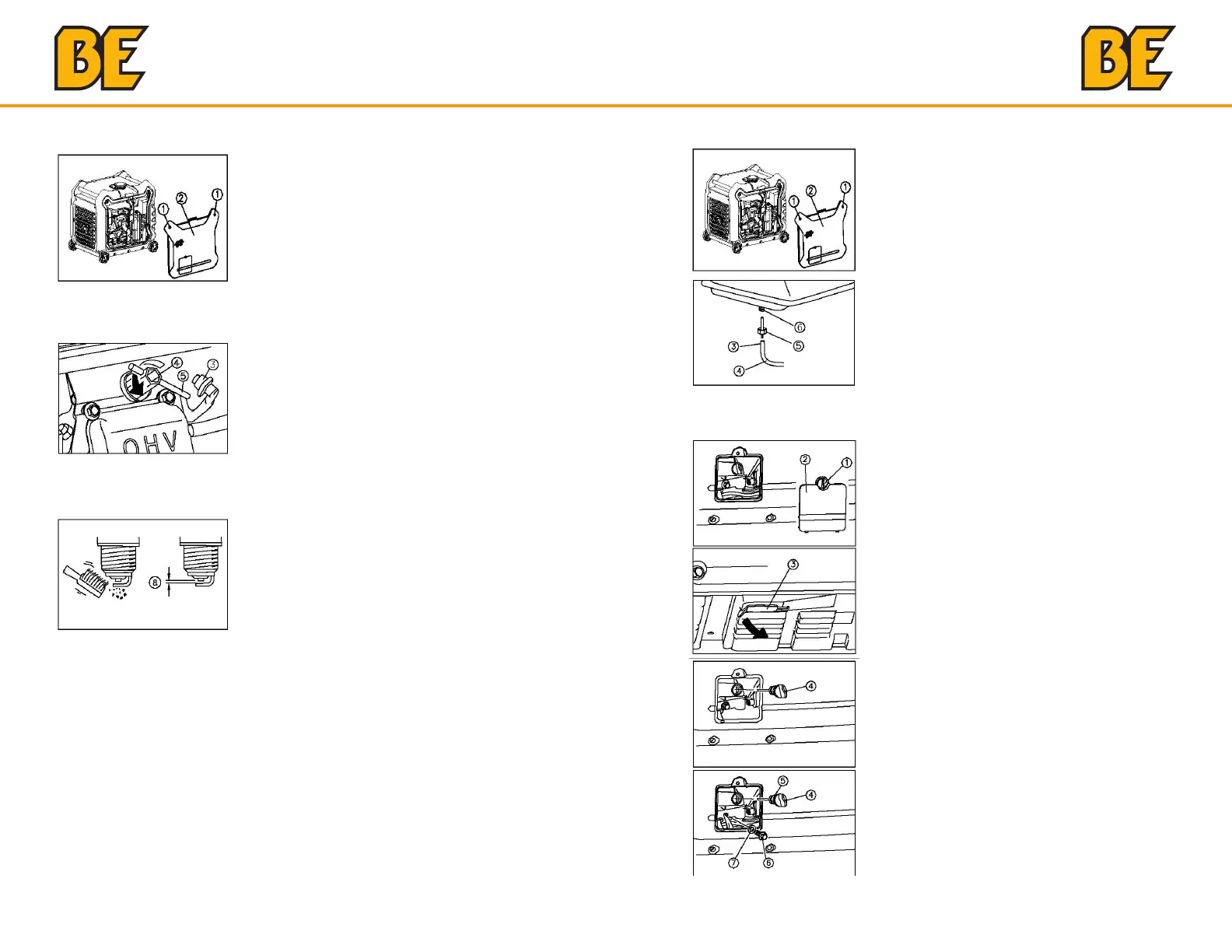

SPARK PLUG INSPECTION

CARBURETOR ADJUSTMENT

The spark plug is important engine

components, which should be checked

periodically.

1. Unscrew and take off the left exterior

cover.

2. Remove the noise suppressor cap assy

install spark plug box wrench on the

spark plug appropriately.

3. Insert the handlebar in to the tool and

turn it counterclockwise to remove the

spark plug.

4. Check for discoloration and remove the

carbon. The porcelain insulator around

the center electrode of spark plug should

be a medium-to- light tan color.

5. Check the spark plug type and gap.

Standard spark plug: BPR6ES/BP6ES

GK F7RTC F7TC

Spark plug gap: 0.6-0.7mm

6. Install the spark plug.

TIP: If a torque wrench is not available

when installing a spark plug, a good esti-

mate of the correct torque is 1/4-1/2 turn

past finger tight. However, the spark plug

should be tightened to the specified torque

as soon as possible.

7. Install the spark plug cap and spark plug

cover.

The carburetor is a vital part of the engine. Adjusting should be left to a

dealer with the professional knowledge, specialized tools, and equipment

to do so properly.

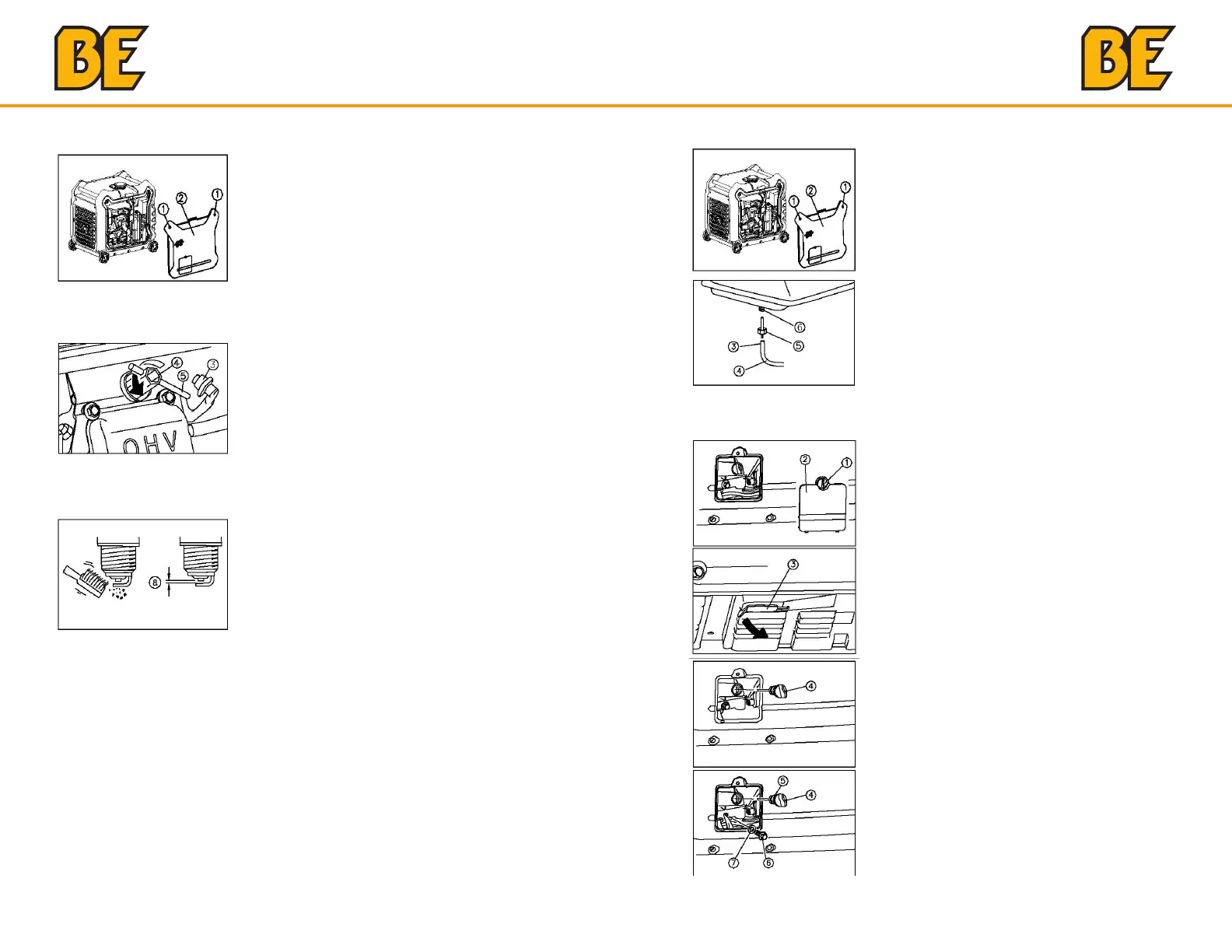

CLEAN FUEL FILTER

ENGINE OIL REPLACEMENT

1. Unscrew the screw (1) and take off the left

exterior cover (2).

2. Drain the fuel in the fuel tank. Hold the

tube clip (3) toward downward and pull

out the fuel tube (4) which is connected to

the fuel tank, then disassemble fuel filter.

3. Put the fuel filter (5) into noncombustible

or higher flash point solvent and clean it.

4. Assemble fuel filter to the main jet (6) on

the fuel tank then install tube clip.

Avoid draining the engine oil immediately after

stopping the engine. The oil is hot and should

be handled with care to avoid burns.

1. Place the generator on a level surface and

warm up the engine for several minutes.

2. Unscrew the screw (1) and take off the

sight glass of engine oil (2).

3. Lift and tilt the machine; take off the end

cap (3) at the bottom plate of machine

4. Remove the oil filler cap.

5. Place an oil pan under the engine, remove

the oil drain bolt (6) drain the oil from the

oil tank.

6. Check oil filler cap (4), O-ring (5), Oil drain

bolt (6), Oil filler cap packing (7). Replace

immediately with new components if any

are damaged.

7. Assemble oil drain bolt and oil filler cap

packing.

8. Add oil to a suitable level, tighten oil filler

cap.

9. Assembly the end cap at the bottom of

machine .

10. Assembly the sight glass of engine oil.

MAINTENANCE MAINTENANCE

Loading...

Loading...