Group 22

Quick Reference

3

SUPPLY POWER

TERMINALS 1, 2, AND 3

Standard supply power for the model 22-309 is

single-phase 120 VAC (refer to the drive nameplate

for specific rating). Input power connects line to

terminal 1, neutral to terminal 2, and ground to

the enclosure power ground screw. Terminal 3 is

unused for 120 VAC operation.

Standard supply power for the model 22-409

is three-phase 208 VAC. Standard supply power

for the model 22-809 is three-phase 480 VAC.

Lines 1, 2, and 3 connect to terminals 1, 2, and 3

respectively on each of these drives. The ground

wire should be connected to the enclosure power

ground screw.

Alternate voltage options include single-phase

240 VAC for the model 22-309 and three-phase

208, 240, 380, 416, 480, & 575 VAC for all Group

22 models. The model 22-309 and 22-409 require

an optional transformer enclosure to accommodate

any non-standard voltage configuration.

Group 22 drives are equipped with a transient

protector assembly installed across each, or a

combination of terminals 1, 2, and 3 (dependent

upon your drive model and configuration). Note:

The transient protector assembly should not be

removed.

AUXILIARY LIMIT SWITCHES

TERMINALS 4 THROUGH 9

Group 22 drives include two single pole double

throw (SPDT) auxiliary limit switches rated for 1

Amp at 250 VAC. These switches may be useful

for discrete position indication. The limit switches

are actuated by adjustable cams on the control

shaft (located with the position sensing device).

Details on standard factory switch settings can be

found in the configuration section of this manual.

AUTO MODE INDICATION

TERMINALS 10 AND 11

A dry contact is available at terminals 10 and

11 to indicate when the handswitch is in the AUTO

position. The switch contact is Form A; when

the handswitch is not in the AUTO position, the

contact is open and when the handswitch is in the

AUTO position, the contact is closed. The contact

is rated for 1 Amp at 250 VAC.

CAUTION

Always close covers immediately after

installation or service to prevent moisture or

other foreign matter from entering the drive.

SYSTEM ALARM

TERMINALS 12 AND 13

Indication of the system alarm is available as

a dry contact at terminals 12 and 13. The factory

standard is a form B contact configuration (open on

alarm). It is configurable to a form A configuration

(closed on alarm). Reference the configuration

section of the manual for additional details on how

to change this functionality. The contact is rated

for a maximum of 80 milliamps at 120 VAC/VDC.

DEMAND SIGNAL

TERMINALS 14 AND 15

The DCM monitors an analog 4-20 milliamp

input signal at terminals 14 (–) and 15 (+), and

positions the output shaft position to match in

response. The standard response is to follow the

demand signal linearly.

FEEDBACK SIGNAL

TERMINALS 16 AND 17

When feedback sourcing is enabled, the DCM-2

transmits a 4-20 milliamp position feedback signal

on terminals 16 (–) and 17 (+) that is proportional

to the drive output shaft position.

CONTROL OVERRIDE INPUTS

TERMINALS 18 THROUGH 21

Analog signal operation may be overridden by

using discrete input signals on the control override

input terminals. CW (19), CCW (20), and STOP

(21) terminals require connection to a common

(COM) terminal (18) to perform the override as

shown in the table below.

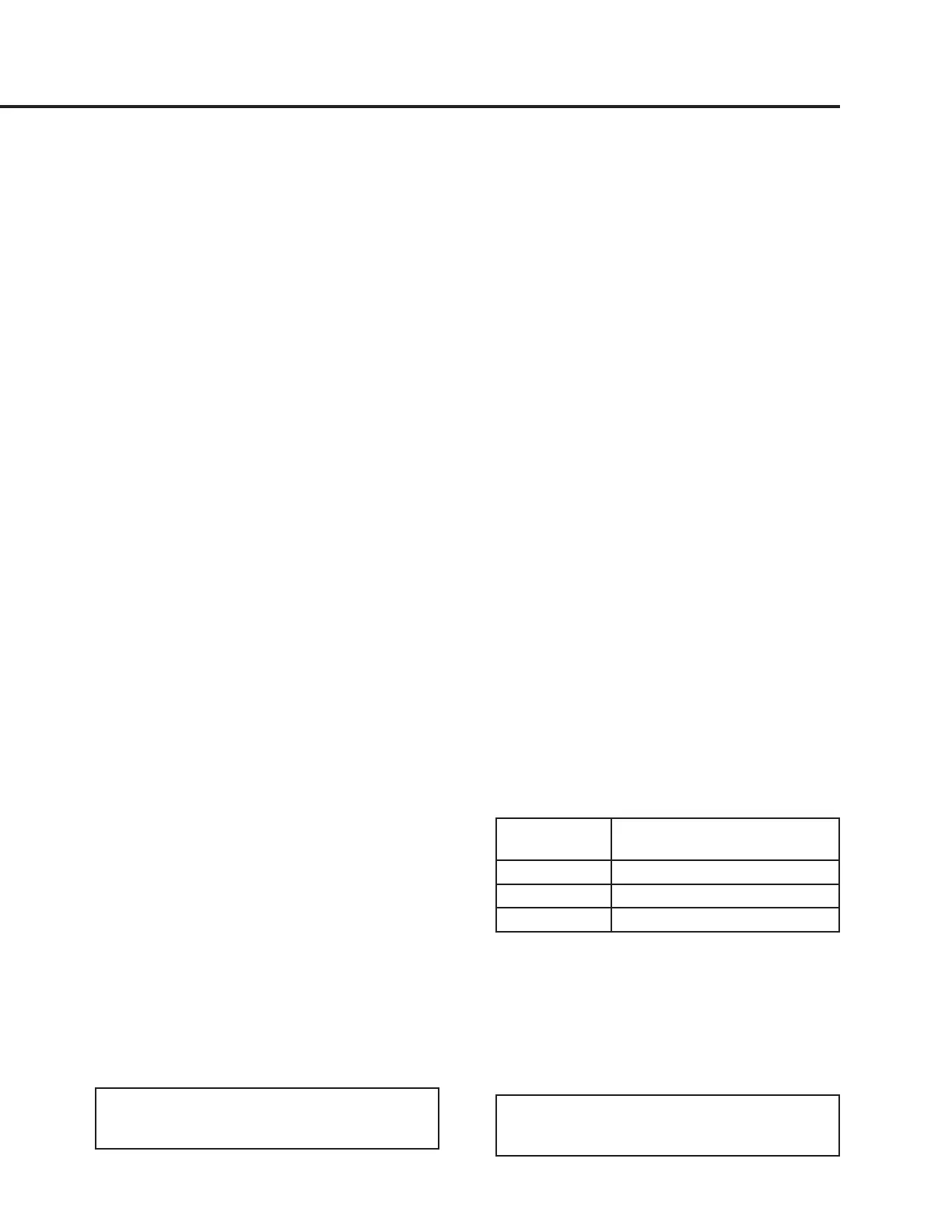

Terminal

Connections

Output Shaft

Action

19 to 18 Clockwise Rotation

20 to 18 Counter-Clockwise Rotation

21 to 18 Stop in Current Position

The connection to terminal 18 is designed to

be made through relay contacts or through a solid

state switch capable of sinking at least 5 milliamps

DC. When the circuit is open, terminals 19, 20,

and 21 should measure +12 VDC with respect to

terminal 18.

CAUTION

Do not connect an external voltage source to

override terminals 18–21; an external voltage

source may damage the DCM circuitry.

Loading...

Loading...