The typical US fire-smoke damper requires 5-15 in-lb torque

per square ft. [6-17 Nm per square meter] at 350°F [171°C]

under dynamic load (2400 fpm [12m/s] velocity).

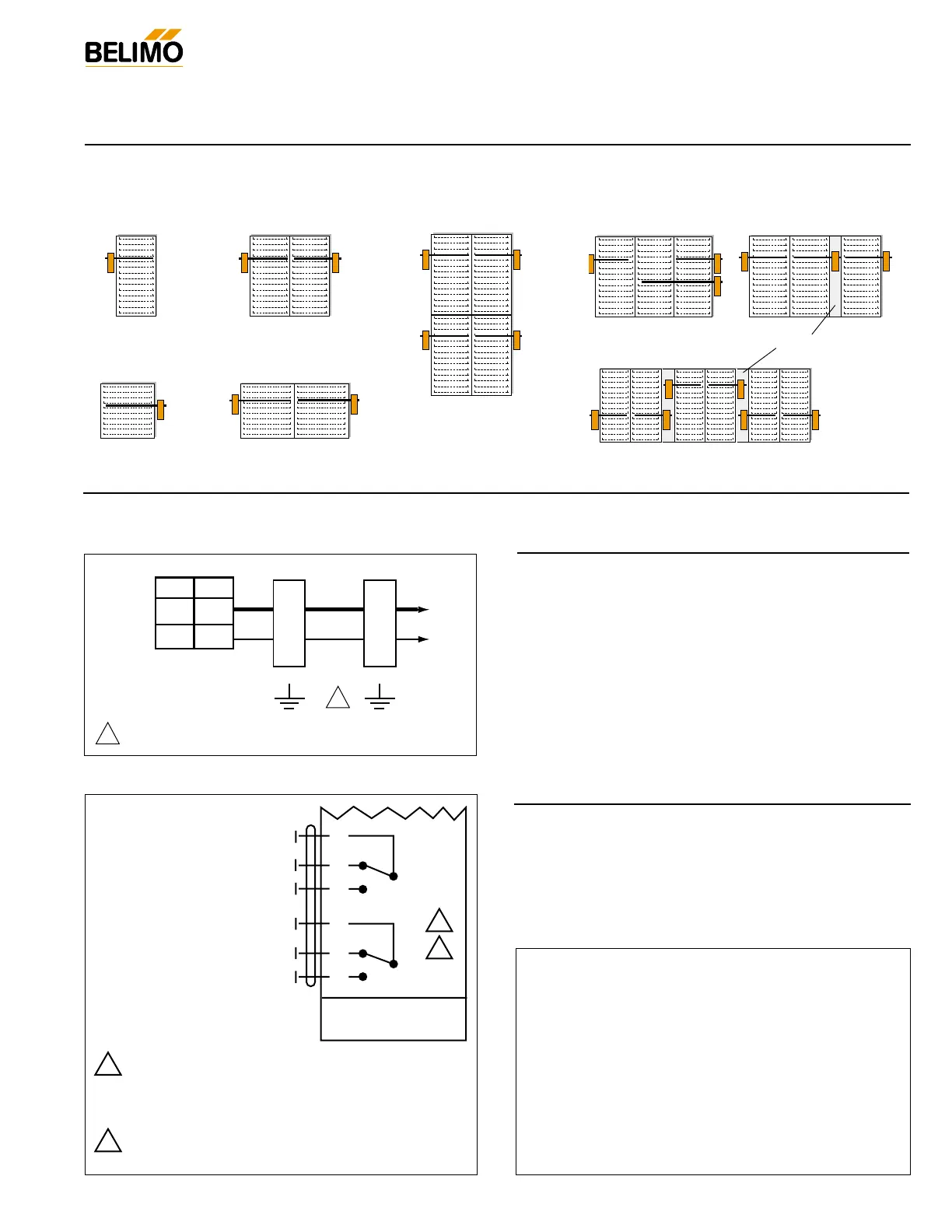

The FSNF will operate multi-section dampers using multiple

actuators for multiple sections. Some of the methods used are

shown below.

Multi-section damper assemblies – typical applications

Application information

Replacement applications

When actuators fail on existing dampers, the local authority having

jurisdiction sets the code requirements for replacement actuators.

The local inspector or fire marshal should be consulted. In most

jurisdictions, the replacement actuator must be “equal or

better”.

The FSNF will meet or exceed requirements, in most applications.

Caution must be used when replacing failed motors with new

Belimo actuators. Many old competitive motors did not have

internal springs and depended on external springs on the side of the

damper or wrapped around the damper shaft to close the damper.

Remove excess parts without interfering with fire functions.

In some cases, the damper must be replaced because the

damper would have to undergo major modifications to replace

an actuator.

Call Belimo to obtain a pdf version of a guide to replacement

smoke damper actuators including a checklist for proper testing.

Smoke Control and Combination Fire and Smoke Control

Actuator FSNF

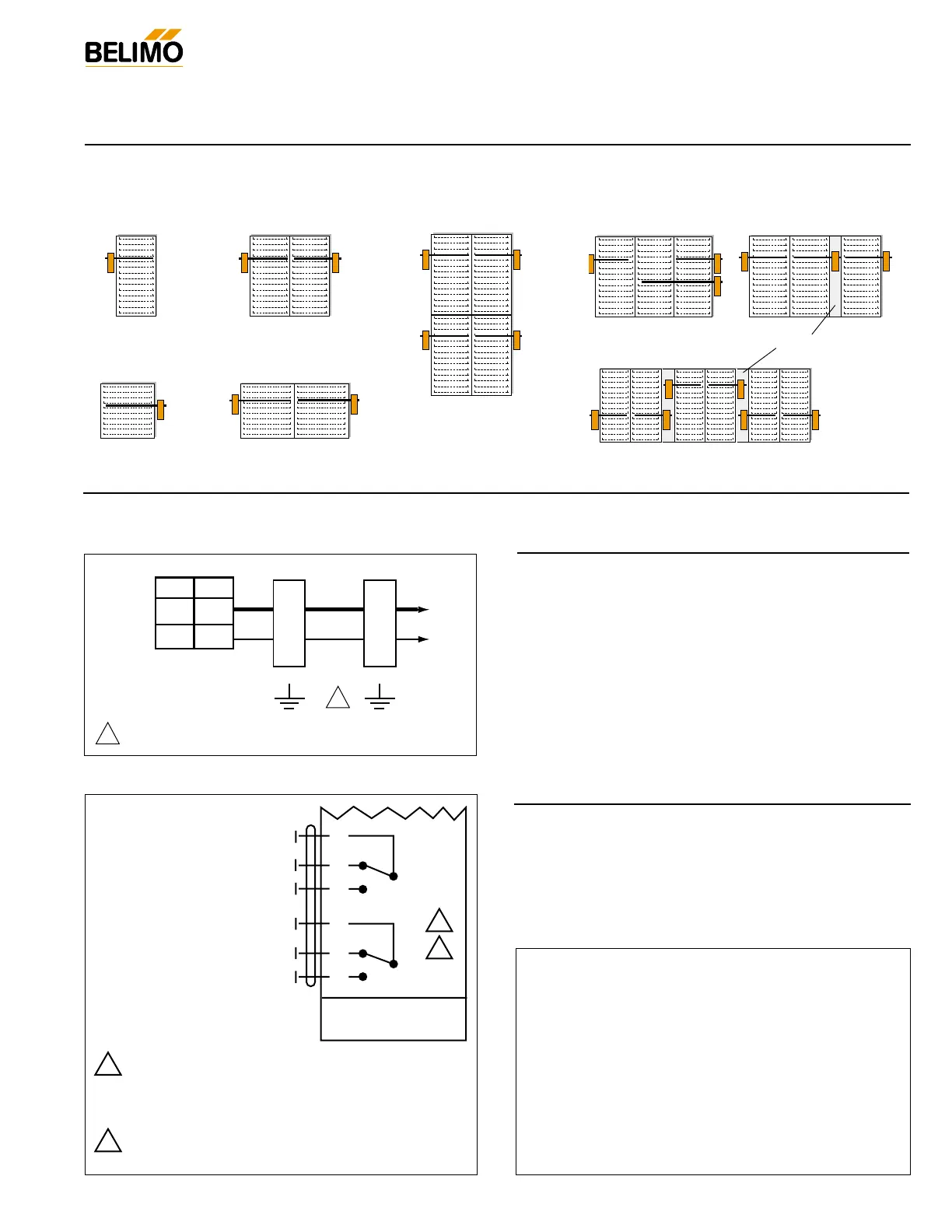

All smoke and combination fire and smoke dampers shall be

provided with Belimo FSNF US actuators. No substitutions

allowed.

Damper and actuator shall have UL555S Listing for 350°F [171°C]

(250°F [121°C]) and shall drive open in 15 seconds and spring

closed in 15 seconds.

Typical specification

electrical ground connection.

Loading...

Loading...