STEP 10

( Power-Unit Start Up )

1. Have a certified electrician run 208 - 230 volt

single phase 60 HZ power supply to motor. ( If you

ordered optional three phase power refer to the

data plate found on the motor for proper power

supply. ) Be sure to size wire for a 25 amp circuit.

RISK OF EXPLOSION!

This equipment has internal arcing or parts that

may spark and should not be exposed to

flammable vapors. Motor should not be located in

a recessed area or below floor level. NEVER

expose motor to rain or other damp environments.

DAMAGE TO MOTOR CAUSED BY WATER IS

NOT COVERED UNDER WARRANTY.

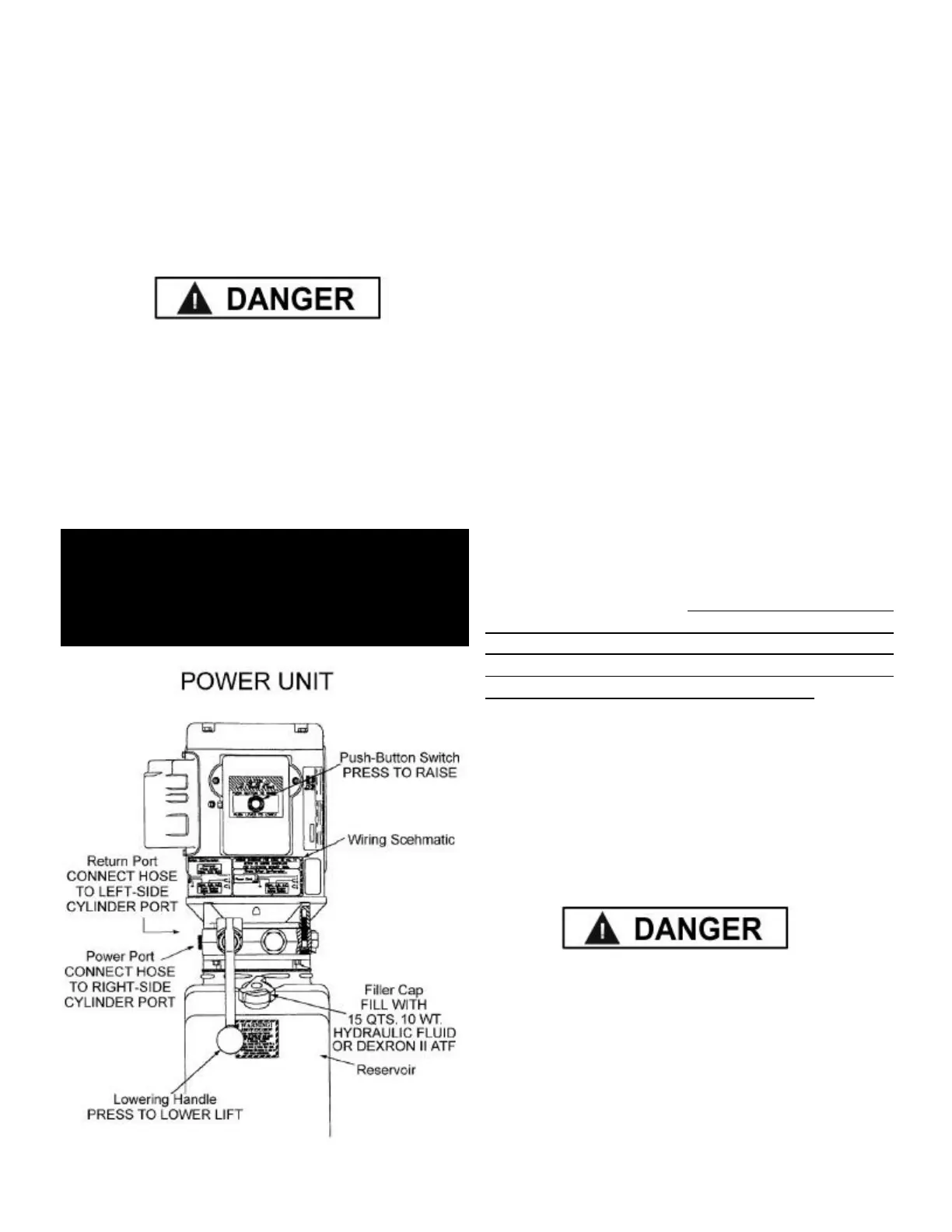

STEP 11

( Lift Start Up )

1. Make sure the power unit reservoir is full with

15 quarts of 10-WT hydraulic oil or Dexron-III

automatic transmission fluid.

2. Spray the inside of the columns where the slide

blocks glide with a light lubricant or WD-40.

3. Test the power unit by depressing the push-

button switch. If the motor sounds like it is

operating properly, raise lift and check all hose

connections for leaks.

SOUNDS PECULIAR, STOP IMMEDIATELY AND

RE-CHECK ELECTRICAL CONNECTIONS.

4. Once the lift starts to raise, simultaneously

press the power unit lowering handle at the same

time you are pressing the raise button. This will

allow any air trapped in the cylinder and lines to

escape and vent into the fluid reservoir.

5. Continue raising the lift slowly until all the slack in

the cables is taken out.

THE CYLINDER BOTTOMS OUT AND THE LIFT

STOPS. ADJUST EACH CABLE SO THAT THE

SAFETY LOCKS REST AT ONE INCH ABOVE

THE TOP SAFETY LOCK POSITION.

necessary to tighten or loosen each cable to reach

the proper height. The nylon cable nuts MUST be

tightened on each end until there is at least 1/4” of

threads through the nylon end of the nut.

STEP 12

( Installing Slack Safety Springs )

The following steps involve the SLACK CABLE

SAFETY DEVICE and MAIN SAFETY. Failure to

follow these steps could result in serious injury

or death in the event of cable failure.

1. Install the SLACK SAFETY LOCK SPRINGS

on the REAR CROSS TUBE as shown. Make

sure spring ends are secure at both ends. ( See

Fig. 14 )

IMPORTANT NOTE:

DO NOT USE 110 VOLT POWER SUPPLY for

this power unit. damage to motor will occur which

is not covered under warranty. You must use a

separate circuit breaker for each lift.

Loading...

Loading...