4

NON-COMPRESSION OF AIR (UNLOADED)

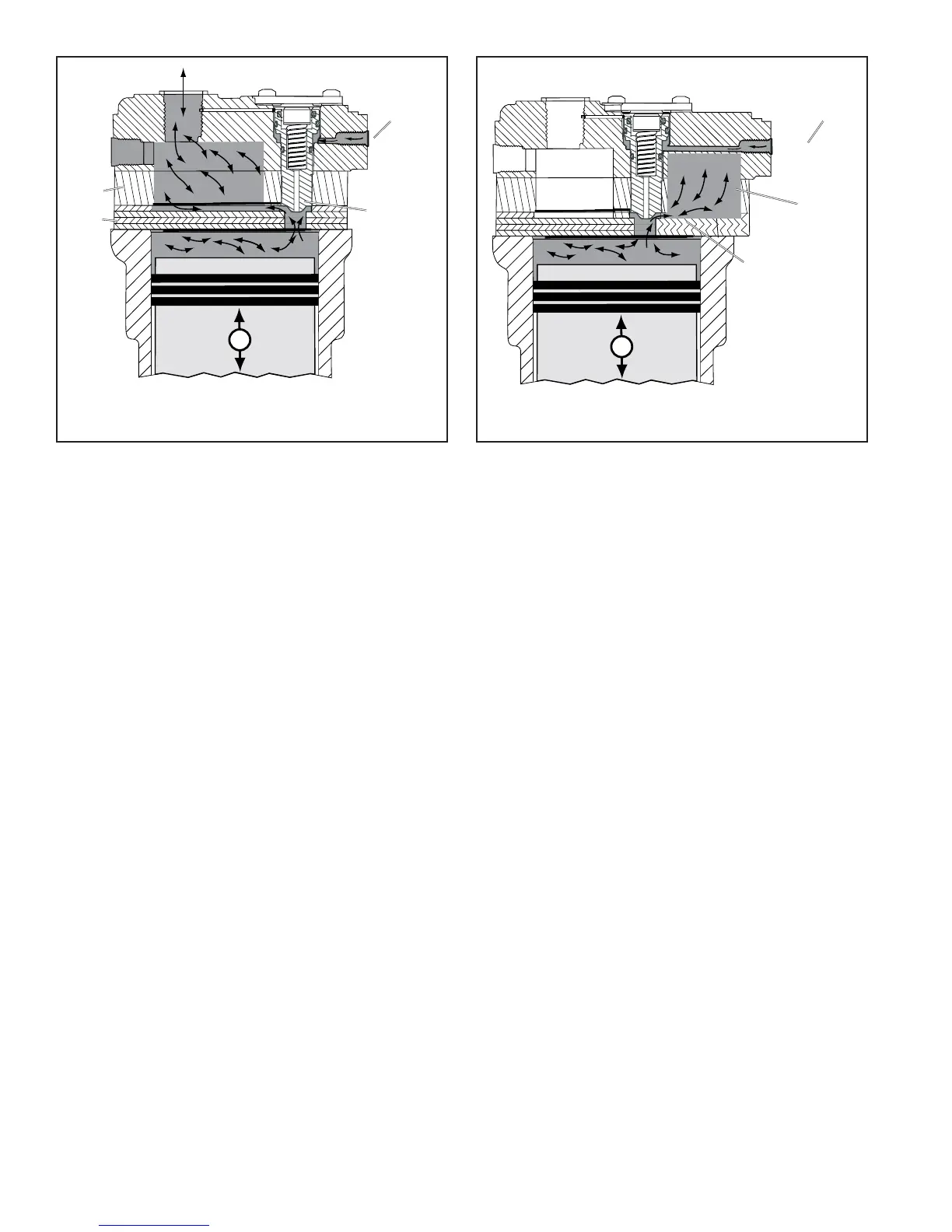

Section 1: For Standard Compressor. See Figure 8.

When air pressure in the supply reservoir reaches the

cutout setting of the governor, the governor delivers

system air to the compressor unloader port. Air entering

the unloader port acts on the unloader piston causing the

piston to move upwards, away from its seat on the valve

plate assembly. When the unloader piston is unseated

an air passageway is opened between the cylinder bore

and the air inlet cavity in the cylinder head.

As the piston moves from bottom dead center (BDC) to

top dead center (TDC) air in the cylinder bore fl ows past

the unseated unloader piston, into the cylinder head inlet

cavity and out the inlet port. To prevent the air from fl owing

back into the engine air induction system, an inlet check

valve (ICV) is installed upstream of the air compressor inlet

port. The location of the device and the way it is plumbed

into the compressor air induction system is unique to the

specifi c engine and the type of air induction (naturally

aspirated or boosted air) the compressor uses. These air

induction systems will be explained in further detail in the

“Air Induction” section on page 4. On the piston down

stroke (TDC to BDC) air fl ows in the reverse direction, from

the inlet cavity past the unseated unloader piston and inlet

reed valve, and into the cylinder bore.

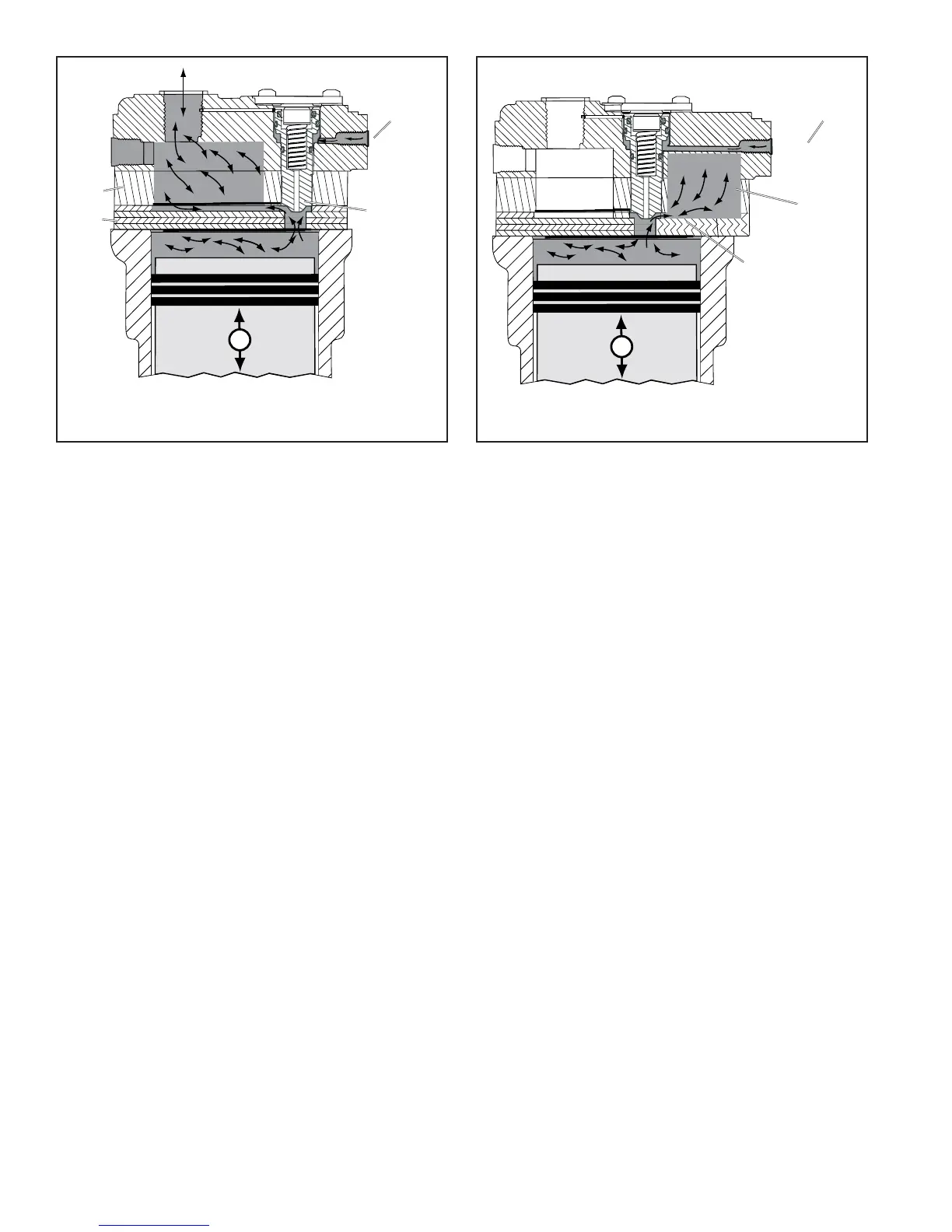

Section 2: For Closed Room Compressor. See Figure 9.

When air pressure in the supply reservoir reaches the

cutout setting of the governor, the governor delivers

system air to the compressor unloader port. Air entering

the unloader port acts on the unloader piston causing

the piston to move away from its seat on the valve plate

assembly. When the unloader piston is unseated, an air

passageway is opened between the cylinder bore and a

secondary compartment or “closed room” in the interior of

the cylinder head.

As the piston moves from bottom dead center (BDC) to top

dead center (TDC) air in the cylinder bore fl ows past the

unseated unloader piston, into the “closed room”. The size

of the closed room is suffi cient to accept the compressed

air provided by the compressor piston without creating

excessive air pressure in the “closed room”. On the piston

down stroke (TDC to BDC) air fl ows in the reverse direction,

from the “closed room” past the unseated unloader piston

and inlet reed valve, and into the cylinder bore. Note: For

optimum performance, it is recommended that the air dryer

is equipped with “turbo cut-off”.

FIGURE 8 - OPERATION - UNLOADED (STANDARD)

Air From

Governor

Unloader

Port

Air Inlet Port

Valve

Plate

Air in Pistons Shuttles Back and Forth from the

Piston to the Cylinder Head and Inlet Port During

Unloaded Mode

Unloader

Piston Up &

Unseated

Cooling

Plate

FIGURE 9 - OPERATION - UNLOADED (CLOSED ROOM)

Air From

Governor

Unloader

Port

Air in Pistons Shuttles Back and Forth from the

Piston to the Closed Room

Unloader

Piston Up &

Unseated

Closed

Room

Loading...

Loading...