5

LUBRICATION

The vehicle's engine provides a continuous supply of oil

to the compressor. Oil is routed from the engine to the

compressor's oil inlet. An oil passage in the crankshaft

routes pressurized oil to the precision sleeve main bearings

and to the connecting rod bearings. Spray lubrication of

the cylinder bores, connecting rod wrist pin bushings, and

ball type main bearings is obtained as oil is forced out

around the crankshaft journals by engine oil pressure.

Oil then falls to the bottom of the compressor crankcase

and is returned to the engine through drain holes in the

compressor mounting fl ange.

Standard Compressor Lubrication for Caterpillar C11

and C13 engine applications

Bendix

®

BA-921

®

compressor - for Caterpillar C11 and

C13 engine installations only - use an "oil jet" that sprays

oil under the piston for purposes of cooling. This oil jet

is part of a special crankcase cover that is used only on

the BA-921

®

compressor for CAT C11 and C13 engine

installations (see Figure 17).

This design slightly alters the fl ow of oil for lubrication. The

oil supply line from the engine is directly connected to the

back side of the special crankcase over. The oil fl ows in

parallel through a passageway in the crankcase cover and

through the oil jet to spray oil under pressure up onto the

underneath of the piston for cooling. At the same time,

oil fl ows out of the opposite end of the special crankcase

cover, through a fi tting and a metal tube and second fi tting

into the oil supply port of the compressor. At this point oil

fl ows in a similar manner as in the fi rst paragraph of this

section.

COOLING

Bendix

®

BA-921

®

compressors are cooled by air fl owing

through the engine compartment as it passes the compres-

sor's cast-in cooling fi ns and by the fl ow of engine coolant

through the cylinder head. Coolant supplied by the engine

cooling system passes through connecting lines into the

cylinder head and passes through internal passages in

the cylinder head, cooling plate and valve plate assembly

and returns to the engine. Figures 10 and 11 illustrate the

various approved coolant fl ow connections. Proper cooling

is important in minimizing discharge air temperatures - see

the tabulated technical data on page 18 of this manual for

specifi c requirements.

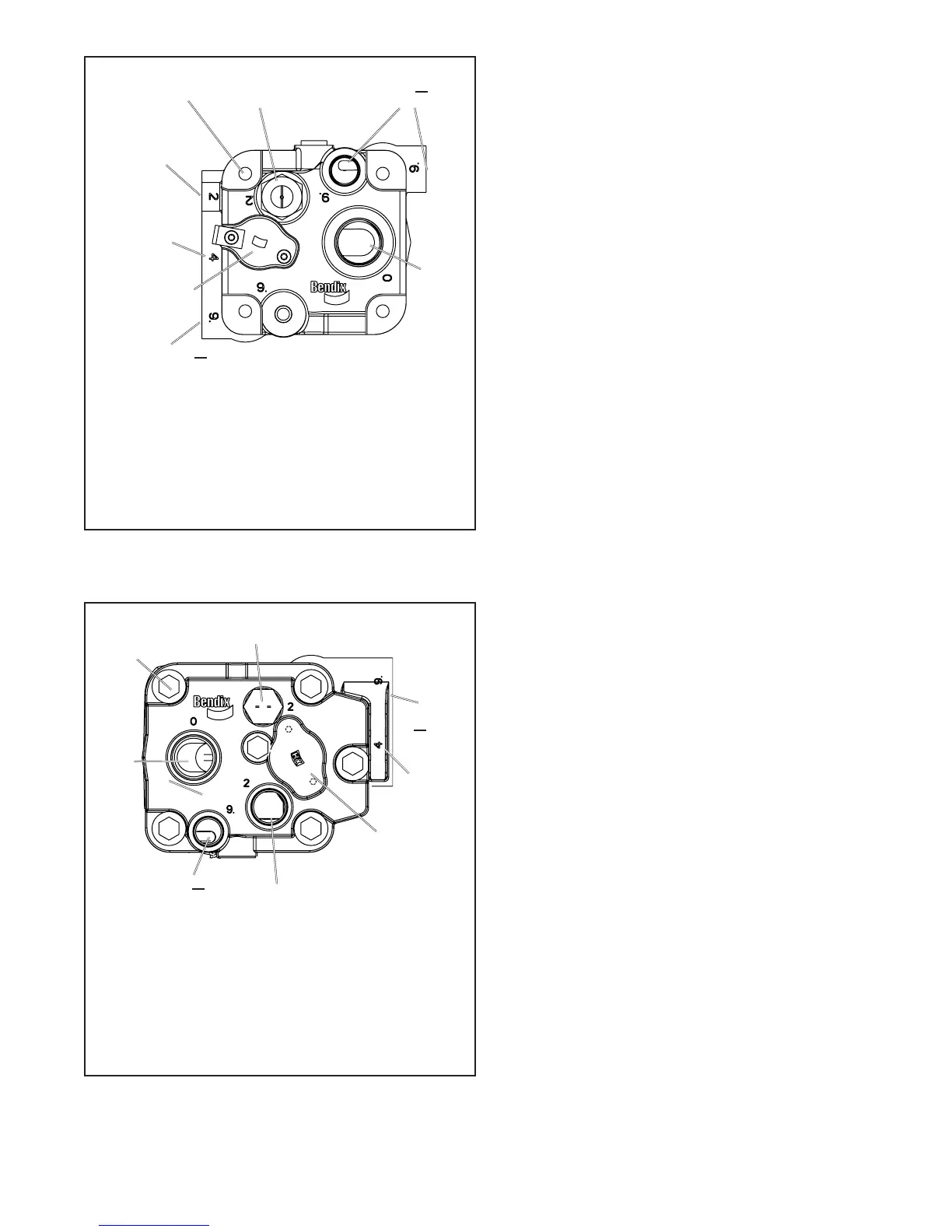

FIGURE 10 - STANDARD BENDIX

®

BA-921

®

COMPRESSOR

CYLINDER HEAD

Discharge

Safety Valve

Discharge

Port

Inlet

Port

Unloader

Cover

Coolant In or Out

Head

Bolt (4)

CYLINDER HEAD PORT IDENTIFICATION

The cylinder head connection ports are identifi ed with cast

in numerals as follows:

AIR IN 0

Compressed AIR OUT 2

Coolant IN or OUT 9

Governor Control 4

Governor

Connection

Coolant In or Out

(One or other not used)

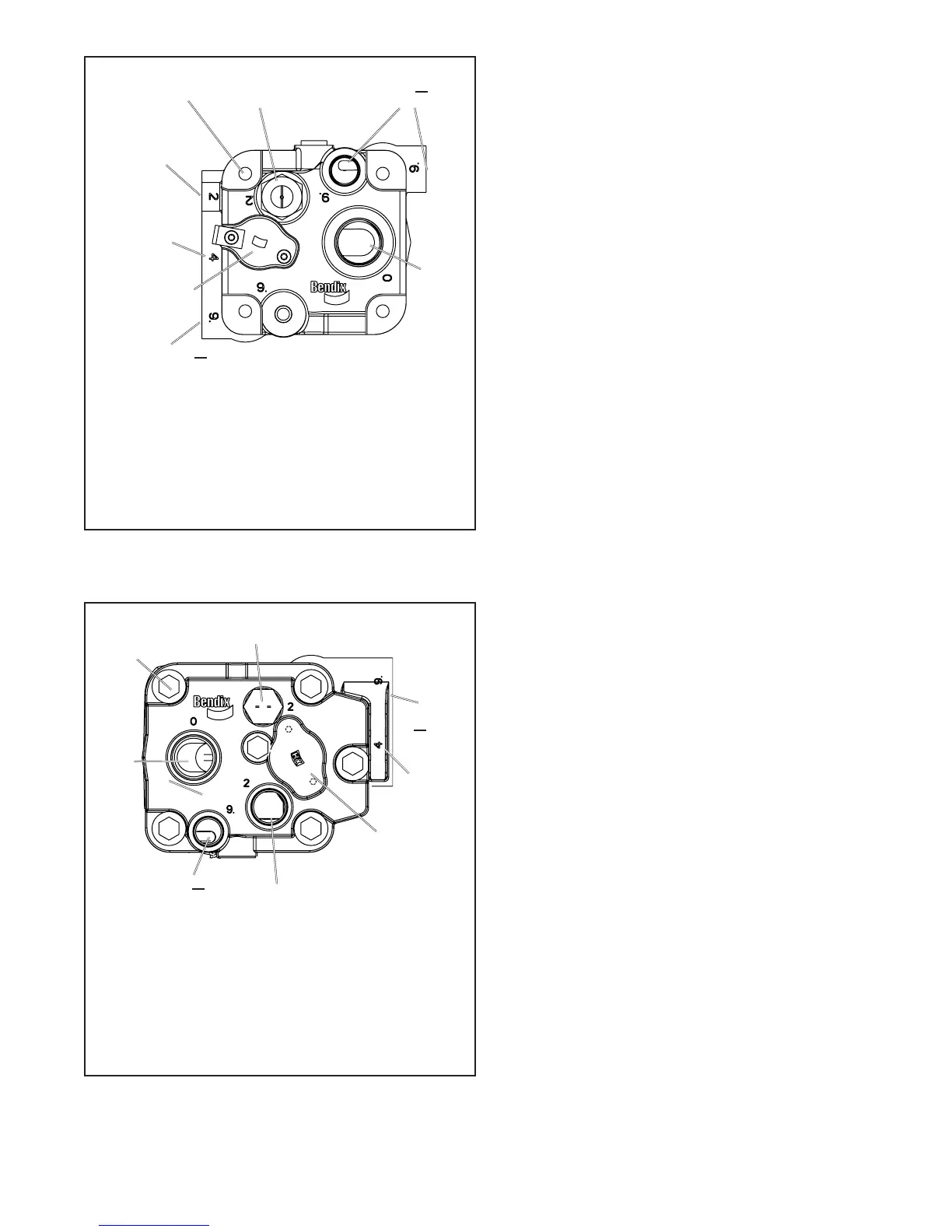

FIGURE 11 - CLOSED ROOM BENDIX

®

BA-921

®

COMPRESSOR CYLINDER HEAD

CYLINDER HEAD PORT IDENTIFICATION

The cylinder head connection ports are identifi ed with cast

in numerals as follows:

AIR IN 0

Compressed AIR OUT 2

Coolant IN or OUT 9

Governor Control 4

Discharge

Safety Valve

Discharge

Port

Inlet

Port

Unloader

Cover

Coolant In or Out

Head

Bolt (6)

Governor

Connection

Coolant In

or Out

(One or other not

used)

Loading...

Loading...