7

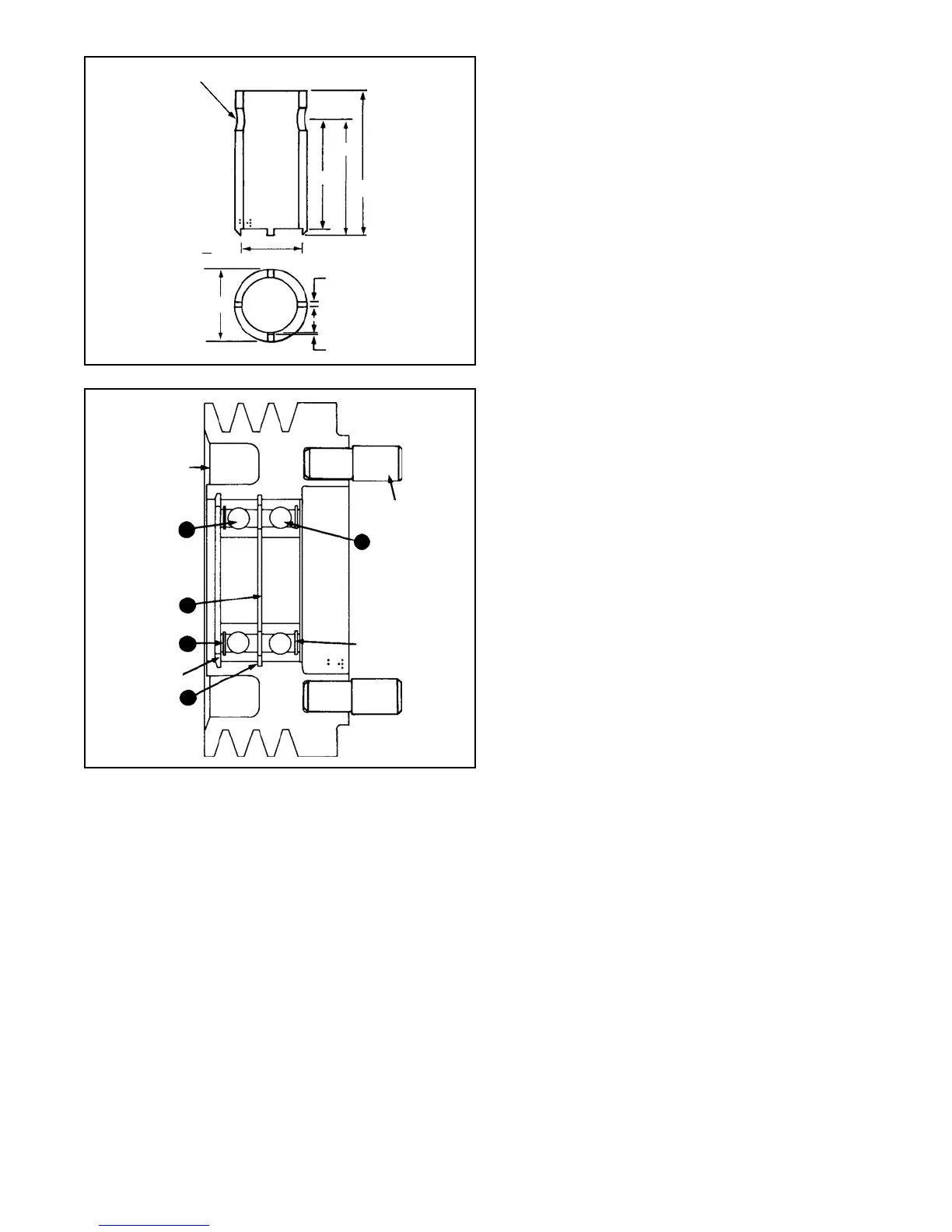

FIGURE 10

MATERIAL O.H.T.S. TUBING

HDN. & DRAW. RC 40-45

27/32” DRILL THRU

(2 HOLES FOR 3/4”

BAR”

2-3/4”

.235 + - .002 CENTERED

(4 LUGS)

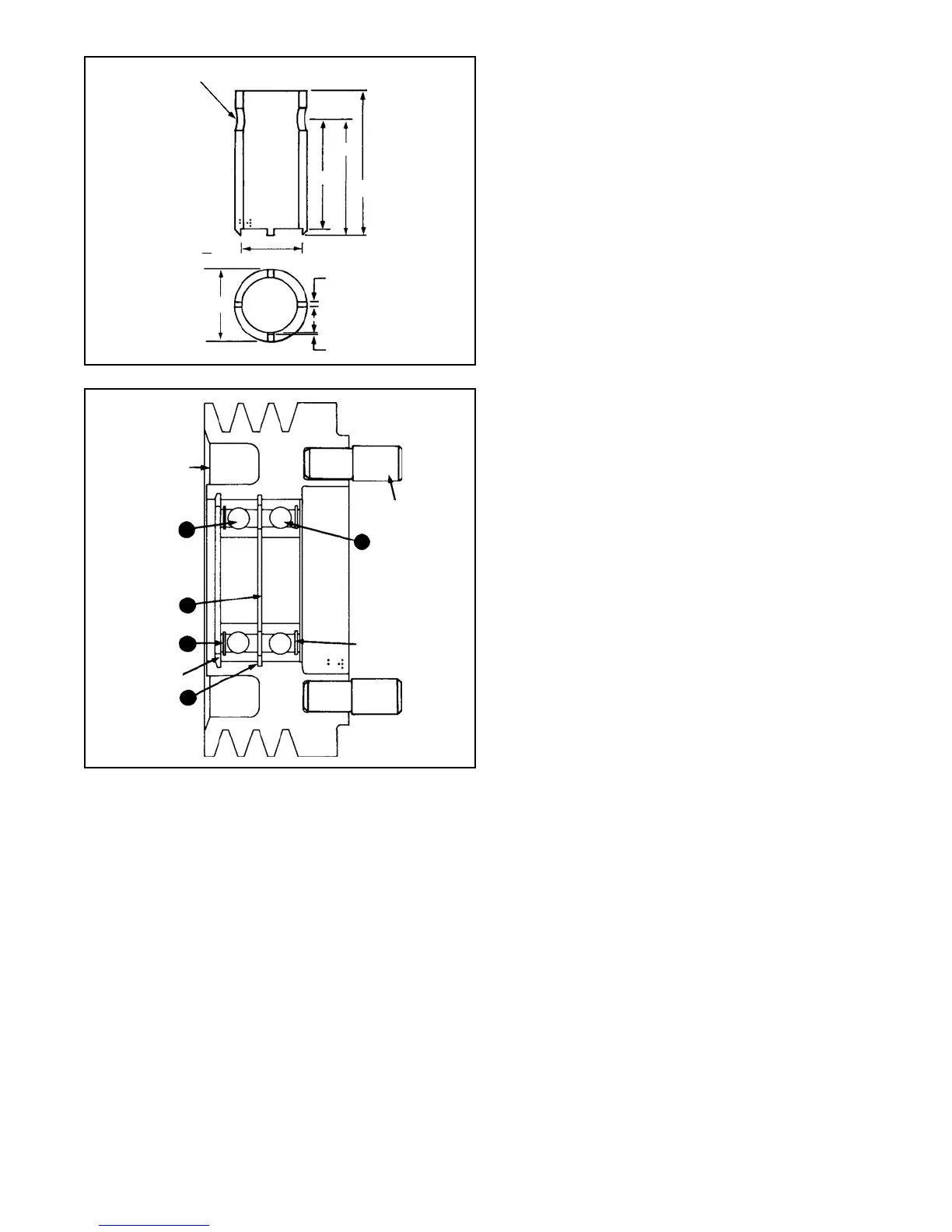

FIGURE 11

DRIVE PINS

PULLEY

22

19

SEAL

19

20

21

SEAL

Displace the bearing spacer(12) so that it is eccentric

to the bearing bore as far as possible. Insert a round

pressing tool through the I.D. of the ball bearing(13)

until it contacts the spacer(12). Press the ball

bearing(11) and the bearing spacer(12) out of the fan

plate. Discard the bearing because it will be damaged

by disassembly.

2. Remove retaining ring(14) using Waldes tool #6500.

Turn fan plate over and press out remaining bearing(13).

Discard the bearing.

FAN PLATE DISASSEMBLY WITH PILOT

DIAMETER OF 2.560

1. Remove the retaining ring(14) from the fan plate. Place

the fan plate on a firm surface and utilizing a round

pressing tool, press out the two ball bearings(13) and

the spacer(12). Discard the bearings.

REASSEMBLY

ASSEMBLY OF PULLEY (Refer to Figure 11)

1. Install snap ring(21) using Waldes tool #6500 or

equivalent.

2. Support the pulley on the drive pin end and press one

of the bearings(19) (seal side up) into the pulley until it

contacts the snap ring(21). Use a pressing tool that

contacts the outer race of the bearing.

3. Turn the pulley over and position the spacer(20)

concentric with the inner race of the previously installed

bearing. Pack grease (Exxon Unirex N-2 or equivalent)

around the spacer making certain not to overfill the

volume. Support both the inner and outer race of the

previously installed bearing. Press in second

bearing(19) (seal side up) using a tool that contacts

both the inner and outer race until the inner race of the

bearing contacts the spacer(20).

4. Turn the pulley over and install the tapered snap ring(22)

(flat side towards the bearing) making sure the snap

ring is fully seated in its groove.

ASSEMBLY OF PULLEY ONTO THE BRACKET

AND SHAFT

1. Support the bracket with the shaft pointing up. Apply

one bank of Loctite RC609 around the shaft at the

location of inner races of the bearings(19) in the pulley.

Also put a band of the Loctite on the inner races of the

bearings(19). NOTE: Parts must BE free of oil and

grease for Loctite to properly bond.

2. Slide the pulley onto the shaft, making sure the bottom

bearings inner race(19) contacts the bracket. Allow 24

hours for complete curing of the Loctite to take affect.

3. Place locking ring(23) on the shaft and install locknut(18)

using the same tool as Step 12 of ‘Disassembly’. Torque

locknut to 100-150 ft. lbs. until one of the tangs of the

lockring(23) can be bent up into one of the slots of the

locknut. Never back the torque off to align parts.

ASSEMBLY OF FAN PLATE WITH 1.998 PILOT

DIAMETER

1. Support the fan plate on the fan mounting surface (nose

down) and press bearing (13) into the housing until it

bottoms against the shoulder of the fan plate. NOTE:

Use a pressing tool that contacts the outer race of the

bearing, do not use a load greater than 1100 lbs. to

press bearing into bore.

2. Turn fan plate over and fully support the previously

installed bearing (13) both inner and outer race. Install

spacer (12) concentric with the inner race of bearing

(13). Press in bearing (11) with a tool that contacts

both the inner and outer race and with a force no greater

than 1100 lbs. until the inner race contacts the spacer.

2.125 + .010

1/32” FLAT

Loading...

Loading...